Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV Fire Barriers + HEPR Insulated, LSOH (SHF1) Sheathed, Screened Fire Resistant Power & Control Cables (Single Core)

Application | These cables are used for fixed installations on ships and offshore units in all locations and on open deck in safety circuits, where fire resistance is required. The good screening qualities of the copper braid also reduce radio interference and electrical influences to electronics installations. These cables are fire resistant, flame retardant, low smoke & halogen free. |

Standards | DIN 89160/98 |

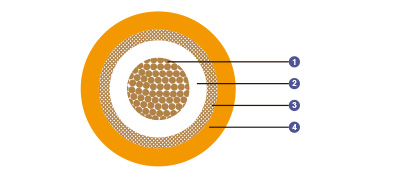

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | Fire barriers + HEPR. |

Overall Screen | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Single core: Natural colour (beige). |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

M092-FR0.6/1KV-1MG7MH-R-1C25 | 1×25 | 0.9 | 1.2 | 12.5 | 380 |

M092-FR0.6/1KV-1MG7MH-R-1C35 | 1×35 | 0.9 | 1.2 | 13.5 | 480 |

M092-FR0.6/1KV-1MG7MH-R-1C50 | 1×50 | 1.0 | 1.3 | 15.5 | 670 |

M092-FR0.6/1KV-1MG7MH-R-1C70 | 1×70 | 1.1 | 1.4 | 17.5 | 900 |

M092-FR0.6/1KV-1MG7MH-R-1C95 | 1×95 | 1.1 | 1.4 | 19.5 | 1170 |

M092-FR0.6/1KV-1MG7MH-R-1C120 | 1×120 | 1.6 | 1.5 | 21.0 | 1430 |

Introduction

In the demanding environments of maritime and offshore installations, the reliability and safety of electrical systems are paramount. Among the critical components ensuring operational integrity are 0.6/1 kV fire resistant power and control cables, specifically designed with fire barriers, High Electron Proton Rubber (HEPR) insulation, Low Smoke Zero Halogen (LSOH) SHF1 sheathing, and copper braid screening. These cables, adhering to stringent international standards such as DIN 89160/98 and various IEC specifications, are engineered for fixed installations on ships and offshore units. Their fire-resistant, flame-retardant, low smoke, and halogen-free properties make them indispensable in safety-critical circuits, particularly in South Africa’s growing maritime and offshore sectors.

Standards Compliance

These cables comply with several international standards, ensuring their suitability for global maritime and offshore applications:

DIN 89160/98: A German standard for marine cables, ensuring compatibility with European maritime regulations.

IEC 60092-353: Governs the design and testing of power cables for shipboard and offshore use.

IEC 60331-21: Specifies fire resistance requirements, ensuring circuit integrity under fire conditions.

IEC 60332-1 and IEC 60332-3-22: Address flame retardancy, preventing fire propagation along cable runs.

IEC 60754-1/2: Ensures halogen-free properties, minimising toxic gas emissions.

IEC 61034: Confirms low smoke emission, enhancing safety in fire scenarios.

Advantages of Fire Resistant Cables

Enhanced Fire Safety

The primary advantage of these cables is their fire resistance, achieved through the combination of fire barriers and HEPR insulation. In a fire, these cables maintain circuit integrity, ensuring that critical systems such as emergency lighting, fire alarms, and communication networks remain operational. This is particularly vital in maritime settings, where escape routes may be limited, and rapid evacuation is essential.

Low Smoke and Halogen-Free Properties

The LSOH (SHF1) sheathing significantly reduces the risks associated with fire. Traditional PVC cables release dense smoke and toxic halogen gases when burned, posing severe health hazards and reducing visibility. In contrast, LSOH cables produce minimal smoke and no halogen gases, improving safety for crew members and facilitating firefighting efforts. This is especially relevant in South Africa, where maritime safety regulations are stringent due to the country’s extensive coastline and busy ports like Durban and Cape Town.

Electromagnetic Compatibility

The copper braid screen provides excellent protection against RFI and EMI, ensuring the reliable operation of sensitive electronic equipment. In modern ships and offshore platforms, where advanced navigation, communication, and control systems are prevalent, this shielding is critical to preventing malfunctions caused by electrical interference.

Durability in Harsh Environments

The combination of HEPR insulation and LSOH sheathing ensures that these cables can withstand the harsh conditions of marine environments. They resist corrosion from saltwater, degradation from UV exposure, and thermal stress from fluctuating temperatures. This durability is particularly advantageous in South Africa’s offshore oil and gas sector, where platforms operate in challenging conditions off the coast of Mossel Bay or in the Agulhas Current.

Versatility

These cables are suitable for a wide range of applications, from power distribution to control circuits. Their single-core design makes them ideal for high-current applications, while their compliance with international standards ensures compatibility with global maritime and offshore projects. In South Africa, they are used in both commercial shipping and offshore energy projects, supporting the country’s maritime economy.

Applications

Maritime Industry

South Africa’s maritime industry is a significant contributor to the economy, with major ports in Durban, Cape Town, and Port Elizabeth handling substantial cargo and passenger traffic. The 0.6/1 kV fire resistant cables are widely used in shipbuilding and retrofitting projects to ensure compliance with international safety standards. For example, in the Port of Durban, these cables are installed in safety circuits for emergency systems on cargo vessels, ensuring that critical equipment remains operational during fire incidents.

Offshore Oil and Gas

The offshore oil and gas sector in South Africa, particularly around the Mossel Bay Gas Field, relies on these cables for power and control applications on platforms and rigs. The fire-resistant and low-smoke properties are critical in these high-risk environments, where fires can have catastrophic consequences. The cables’ ability to maintain circuit integrity under fire conditions ensures that safety systems, such as gas detection and shutdown mechanisms, remain functional, protecting both personnel and infrastructure.

Case Study: PetroSA’s FA Platform

A notable example is the use of these cables in PetroSA’s F-A Platform, located off the South African coast. The platform, which produces natural gas and condensate, requires robust electrical systems to operate safely in a harsh marine environment. The 0.6/1 kV fire resistant cables were selected for their ability to withstand fire, corrosion, and electromagnetic interference. Their installation in safety circuits, including fire alarms and emergency shutdown systems, has enhanced the platform’s safety profile, reducing the risk of incidents and ensuring compliance with IEC standards.

Renewable Energy Projects

South Africa’s growing offshore renewable energy sector, including wind farms proposed off the Western Cape, also benefits from these cables. Their durability and fire safety features make them suitable for connecting control systems in offshore wind turbines, where reliability is critical to maintaining power generation and grid stability.

Conclusion

The 0.6/1 kV fire resistant power and control cables, with their HEPR insulation, LSOH (SHF1) sheathing, and copper braid screening, represent a pinnacle of engineering for safety-critical applications in maritime and offshore environments. Their compliance with international standards, combined with their fire-resistant, low-smoke, and halogen-free properties, makes them an ideal choice for ensuring safety and reliability in South Africa’s challenging marine conditions. From the busy ports of Durban and Cape Town to the offshore platforms of Mossel Bay, these cables play a vital role in protecting lives and infrastructure. As South Africa continues to expand its maritime and renewable energy sectors, the adoption of these advanced cables will remain a cornerstone of safe and efficient electrical systems.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430