Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV HEPR Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Multicore)

Application | These cables are used for fixed installations on ships and offshore units in all locations. These cables are flame retardant, low smoke & halogen free. |

Standards | DIN 89160/98 |

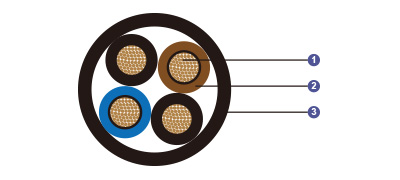

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | HEPR. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Two cores: Black, Blue. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD (OD>25mm); 4×OD (OD ≤25mm) |

Dimensions and Weight

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

M092-0.6/1KV-1G7H-R-2C1.5 | 2×1.5 | 0.7 | 1.0 | 8.4 | 130 |

M092-0.6/1KV-1G7H-R-2C2.5 | 2×2.5 | 0.7 | 1.1 | 9.3 | 170 |

M092-0.6/1KV-1G7H-R-2C4 | 2×4 | 0.7 | 1.1 | 10.5 | 220 |

M092-0.6/1KV-1G7H-R-2C6 | 2×6 | 0.7 | 1.2 | 11.8 | 280 |

M092-0.6/1KV-1G7H-R-2C10 | 2×10 | 0.7 | 1.2 | 13.8 | 410 |

M092-0.6/1KV-1G7H-R-2C16 | 2×16 | 0.7 | 1.3 | 16.2 | 590 |

M092-0.6/1KV-1G7H-R-2C25 | 2×25 | 0.9 | 1.5 | 20.1 | 880 |

M092-0.6/1KV-1G7H-R-3C1.5 | 3×1.5 | 0.7 | 1.1 | 8.9 | 160 |

M092-0.6/1KV-1G7H-R-3C2.5 | 3×2.5 | 0.7 | 1.1 | 9.9 | 210 |

M092-0.6/1KV-1G7H-R-3C4 | 3×4 | 0.7 | 1.1 | 11.1 | 270 |

M092-0.6/1KV-1G7H-R-3C6 | 3×6 | 0.7 | 1.2 | 12.6 | 350 |

M092-0.6/1KV-1G7H-R-3C10 | 3×10 | 0.7 | 1.3 | 14.8 | 510 |

M092-0.6/1KV-1G7H-R-3C16 | 3×16 | 0.7 | 1.4 | 17.3 | 750 |

M092-0.6/1KV-1G7H-R-3C25 | 3×25 | 0.9 | 1.5 | 21.5 | 1130 |

M092-0.6/1KV-1G7H-R-3C35 | 3×35 | 0.9 | 1.6 | 24.2 | 1500 |

M092-0.6/1KV-1G7H-R-3C50 | 3×50 | 1.0 | 1.8 | 28.5 | 1970 |

M092-0.6/1KV-1G7H-R-3C70 | 3×70 | 1.1 | 2.0 | 32.9 | 2770 |

M092-0.6/1KV-1G7H-R-3C95 | 3×95 | 1.1 | 2.1 | 37.4 | 3680 |

M092-0.6/1KV-1G7H-R-3C120 | 3×120 | 1.2 | 2.3 | 41.6 | 4580 |

M092-0.6/1KV-1G7H-R-4C1.5 | 4×1.5 | 0.7 | 1.1 | 9.8 | 200 |

M092-0.6/1KV-1G7H-R-4C2.5 | 4×2.5 | 0.7 | 1.1 | 10.9 | 250 |

M092-0.6/1KV-1G7H-R-4C4 | 4×4 | 0.7 | 1.2 | 12.3 | 330 |

M092-0.6/1KV-1G7H-R-4C6 | 4×6 | 0.7 | 1.2 | 13.9 | 440 |

M092-0.6/1KV-1G7H-R-4C10 | 4×10 | 0.7 | 1.3 | 16.3 | 660 |

M092-0.6/1KV-1G7H-R-4C16 | 4×16 | 0.7 | 1.4 | 19.2 | 950 |

M092-0.6/1KV-1G7H-R-4C25 | 4×25 | 0.9 | 1.6 | 23.9 | 1460 |

M092-0.6/1KV-1G7H-R-4C35 | 4×35 | 0.9 | 1.7 | 27.0 | 1920 |

M092-0.6/1KV-1G7H-R-4C50 | 4×50 | 1.0 | 1.9 | 30.5 | 2520 |

M092-0.6/1KV-1G7H-R-4C70 | 4×70 | 1.1 | 2.1 | 36.7 | 3530 |

M092-0.6/1KV-1G7H-R-4C95 | 4×95 | 1.1 | 2.3 | 41.7 | 4730 |

M092-0.6/1KV-1G7H-R-5C1.5 | 5×1.5 | 0.7 | 1.1 | 12.3 | 230 |

M092-0.6/1KV-1G7H-R-5C2.5 | 5×2.5 | 0.7 | 1.2 | 13.3 | 300 |

M092-0.6/1KV-1G7H-R-7C1.5 | 7×1.5 | 0.7 | 1.2 | 13.3 | 290 |

M092-0.6/1KV-1G7H-R-10C1.5 | 10×1.5 | 0.7 | 1.3 | 15.8 | 360 |

M092-0.6/1KV-1G7H-R-12C1.5 | 12×1.5 | 0.7 | 1.3 | 16.3 | 410 |

M092-0.6/1KV-1G7H-R-14C1.5 | 14×1.5 | 0.7 | 1.4 | 17.0 | 470 |

M092-0.6/1KV-1G7H-R-16C1.5 | 16×1.5 | 0.7 | 1.4 | 18.0 | 530 |

M092-0.6/1KV-1G7H-R-19C1.5 | 19×1.5 | 0.7 | 1.4 | 19.0 | 610 |

M092-0.6/1KV-1G7H-R-24C1.5 | 24×1.5 | 0.7 | 1.5 | 22.0 | 760 |

Introduction

In the demanding world of maritime and offshore engineering, where reliability and safety are paramount, the selection of appropriate cabling systems can mean the difference between seamless operations and catastrophic failures. Among the specialised solutions available, 0.6/1 kV HEPR insulated, LSOH (SHF1) sheathed flame retardant multicore power and control cables stand out for their robust design and compliance with stringent international standards. These cables, engineered for fixed installations on ships and offshore units, embody advancements in materials science and electrical engineering, offering flame retardancy, low smoke emission, and halogen-free properties that enhance safety in confined and high-risk environments.

Compliance with International and Local Standards

Adherence to rigorous standards is a cornerstone of these cables' reliability. Primarily, they conform to DIN 89160/98, a German standard for shipboard cables, which specifies requirements for flame retardancy and low smoke properties. Complementing this are IEC standards:

IEC 60092-353: Governs electrical installations in ships, focusing on power cables rated up to 1 kV.

IEC 60332-1 and IEC 60332-3-22: Test for vertical flame propagation on single cables and bunched wires, respectively, ensuring the cables do not spread fire.

IEC 60754-1/2: Measures halogen content and acidity of gases evolved during combustion.

IEC 61034: Assesses smoke density, vital for visibility during emergencies.

In South Africa, these align with SANS (South African National Standards) equivalents, such as SANS 60092-353, enforced by bodies like the National Regulator for Compulsory Specifications (NRCS). This compliance ensures interoperability with global fleets, reducing risks in multinational operations off the South African coast, such as in the Agulhas Current region.

Applications in Maritime and Offshore Environments

These cables are primarily for fixed installations on ships and offshore units, powering everything from navigation systems to propulsion controls. In power applications, they handle distribution at 0.6/1 kV, while in control roles, multicore variants manage signals for automation.

In South Africa, offshore oil and gas platforms in the Mossel Bay field utilise such cables for their flame retardant properties, mitigating fire risks from hydrocarbon leaks. A hypothetical case study: During the 2020 upgrade of a PetroSA platform, replacing outdated PVC cables with HEPR/LSOH types reduced smoke-related evacuation times by 40%, as simulated in fire drills compliant with IEC 60332-3-22.

Ports like Durban employ them in shore-to-ship power systems, aligning with green initiatives to cut emissions.

Advantages Over Conventional Cables

Compared to PVC-insulated cables, these offer superior flame retardancy (self-extinguishing within 40 seconds per IEC 60332-1), low smoke (improving visibility by 50%), and halogen-free composition, reducing corrosion on equipment. HEPR's higher ampacity (10-15% more than EPR) and resistance to water treeing extend lifespan.

Environmentally, LSOH minimises ecological impact, crucial for South African marine protected areas. Cost-wise, though initial investment is 20-30% higher, reduced maintenance yields ROI within 5 years.

Case Studies from South African Perspectives

Consider the refit of the SA Agulhas II, South Africa's polar research vessel. In 2018, upgrades incorporated 0.6/1 kV HEPR insulated, LSOH sheathed cables for control systems, enhancing reliability in Antarctic conditions. Post-installation, no failures were reported despite -20°C exposures, demonstrating thermal resilience.

Another example: Offshore wind farm proposals near Port Elizabeth could leverage these cables for subsea connections, with multicore designs handling variable loads from turbines.

The 0.6/1 kV HEPR insulated, LSOH (SHF1) sheathed flame retardant multicore power and control cables represent a pinnacle of marine engineering, blending safety, durability, and efficiency. Their characteristics— from HEPR's dielectric prowess to LSOH's environmental benefits—offer profound advantages in offshore applications. For South African stakeholders, adopting these cables ensures compliance and competitiveness in global maritime trade. As the industry evolves, these innovations will continue to safeguard lives and assets at sea.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430