Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV HEPR Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Single Core)

Application | These cables are used for fixed installations on ships and offshore units in all locations. These cables are flame retardant, low smoke & halogen free. |

Standards | DIN 89160/98 |

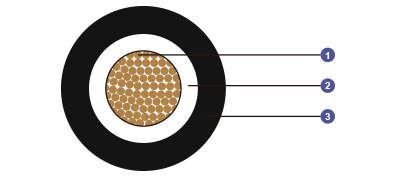

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | HEPR. |

Outer Sheath | LSOH (SHF1) |

Core Identification | Single core: Natural colour (beige). |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD (OD>25mm); 4×OD (OD ≤25mm) |

Dimensions and Weight

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

M092/0.6/1KV--1G7H-R-1C4 | 1×4 | 0.7 | 1.2 | 6.5 | 80 |

M092/0.6/1KV--1G7H--R-1C6 | 1×6 | 0.7 | 1.2 | 7.5 | 110 |

M092/0.6/1KV--1G7H--R-1C10 | 1×10 | 0.7 | 1.2 | 8.5 | 150 |

M092/0.6/1KV--1G7H--R-1C16 | 1×16 | 0.7 | 1.2 | 9.5 | 220 |

M092/0.6/1KV--1G7H--R-1C25 | 1×25 | 0.9 | 1.2 | 11.0 | 320 |

M092/0.6/1KV--1G7H--R-1C35 | 1×35 | 0.9 | 1.2 | 12.0 | 420 |

M092/0.6/1KV--1G7H--R-1C50 | 1×50 | 1.0 | 1.3 | 13.5 | 560 |

M092/0.6/1KV--1G7H-R-1C70 | 1×70 | 1.1 | 1.3 | 15.5 | 780 |

M092/0.6/1KV--1G7H-R-1C95 | 1×95 | 1.1 | 1.4 | 17.8 | 1030 |

M092/0.6/1KV--1G7H-R-1C120 | 1×120 | 1.2 | 1.4 | 19.3 | 1290 |

M092/0.6/1KV--1G7H-R-1C150 | 1×150 | 1.4 | 1.5 | 21.3 | 1590 |

M092/0.6/1KV--1G7H-R-1C185 | 1×185 | 1.6 | 1.5 | 23.5 | 1960 |

M092/0.6/1KV--1G7H-R-1C240 | 1×240 | 1.7 | 1.6 | 26.5 | 2560 |

M092/0.6/1KV--1G7H-R-1C300 | 1×300 | 1.8 | 1.7 | 29.5 | 3200 |

Introduction

In the demanding world of marine and offshore engineering, where reliability, safety, and environmental resilience are paramount, the choice of cabling systems plays a pivotal role. Among the specialised solutions available, 0.6/1 kV HEPR insulated, LSOH (SHF1) sheathed flame retardant power and control cables (single core) stand out as a cornerstone technology. These cables are engineered specifically for fixed installations on ships, offshore platforms, and related units, addressing the unique challenges posed by harsh maritime conditions such as humidity, salt exposure, mechanical stress, and the ever-present risk of fire.

Hard Ethylene Propylene Rubber (HEPR) insulation forms the core of these cables, offering superior electrical and mechanical properties that ensure consistent performance under extreme temperatures and environmental pressures. Combined with a Low Smoke Zero Halogen (LSOH) sheath classified as SHF1, these cables minimise smoke emission and eliminate halogen gases during combustion, thereby enhancing occupant safety and reducing equipment corrosion. This flame retardant design aligns with global standards, making them indispensable in confined spaces where rapid evacuation and minimal toxicity are critical.

South Africa, with its extensive coastline and burgeoning maritime sector, exemplifies the practical application of such cables. From the bustling ports of Durban and Cape Town to offshore oil and gas operations in the Agulhas Current, these cables support vital infrastructure.

Standards and Compliance

Compliance with rigorous international and national standards underpins the reliability of these cables. Primarily, they adhere to IEC 60092-353, which specifies requirements for shipboard and offshore non-radial field power cables with extruded solid insulation rated at 0.6/1 kV (up to 1.2 kV maximum). This standard ensures cables can handle the electrical stresses of marine power systems, including voltage withstand tests and insulation resistance measurements.

Complementing this is DIN 89160/98, a German standard focused on marine cables for passenger ships and special-purpose vessels. It emphasises flame retardancy and low smoke properties, mandating tests for halogen content and smoke density. Additional IEC standards include IEC 60332-1 and IEC 60332-3-22 for flame retardancy, evaluating single cable and bunched cable fire propagation; IEC 60754-1/2 for halogen acid gas emission, ensuring zero halogens; and IEC 61034 for smoke density, guaranteeing low obscuration in fires.

These standards collectively assure that the cables perform safely in offshore environments. For example, IEC 60092-353 requires cables to maintain functionality under humid, saline conditions, with tests simulating ship vibrations and thermal cycling. In South African contexts, compliance aligns with local regulations under the South African Maritime Safety Authority (SAMSA), which harmonises with IMO (International Maritime Organization) guidelines, promoting global interoperability.

Manufacturers must conduct type tests, including bending radius evaluations and temperature endurance, to certify compliance. This rigorous framework not only mitigates risks but also facilitates insurance and certification for vessels operating in international waters, such as those from South African ports engaging in global trade.

Key Characteristics

The characteristics of these cables encompass electrical, mechanical, thermal, and environmental attributes, making them ideally suited for marine demands.

Electrically, the HEPR insulation provides high dielectric strength, with insulation resistance often exceeding industry norms. The single-core design minimises electromagnetic interference, crucial for control circuits in navigation and automation systems. Voltage ratings of 0.6/1 kV support a wide range of applications, from lighting to motor drives.

Mechanically, bending radii of 6×OD for diameters over 25 mm and 4×OD for smaller ones allow flexible installation without kinking. Stranded conductors enhance fatigue resistance against ship motions.

Thermally, the cables operate from -20°C to +75°C, with HEPR allowing conductor temperatures up to 90°C continuously and 130°C in overloads. This thermal stability prevents degradation in hot engine compartments or cold polar routes.

Environmentally, the LSOH SHF1 sheath ensures low smoke (typically <60% obscuration) and zero halogens, reducing toxicity. Flame retardancy meets Category A bunch tests, limiting fire spread.

In terms of dimensions, a comprehensive range caters to varying power needs: from 1×4 mm² (6.5 mm OD, 80 kg/km) for light loads to 1×300 mm² (29.5 mm OD, 3200 kg/km) for heavy-duty applications. These specs enable precise selection based on current-carrying capacity and voltage drop calculations.

Overall, these characteristics confer durability in corrosive marine atmospheres, with resistance to oil and chemicals preventing insulation breakdown.

Advantages

The advantages of these cables are multifaceted, spanning safety, performance, and sustainability.

Foremost is enhanced fire safety: LSOH materials produce minimal smoke and no corrosive halogen gases, aiding visibility and evacuation in fires—a critical factor in offshore platforms where escape routes are limited. This reduces secondary damage to electronics and structures from acid formation.

Performance-wise, HEPR's superior insulation properties extend cable lifespan, with better resistance to water treeing and aging compared to XLPE alternatives. Lower weight and smaller diameters optimise space and reduce installation costs on ships.

Sustainability benefits include halogen-free composition, aligning with environmental regulations like REACH and RoHS. In offshore environments, their robustness minimises maintenance, lowering operational downtime and carbon footprints.

Economically, while initial costs may be higher than PVC cables, long-term savings accrue from reduced fire risks and extended service life—up to 30 years in marine settings.

In South African offshore oil rigs, these advantages translate to compliance with stringent safety protocols, enhancing worker protection amid hazardous conditions.

In summary, 0.6/1 kV HEPR insulated, LSOH (SHF1) sheathed flame retardant single core power cables embody innovation in marine engineering. Their robust construction, standards compliance, and superior characteristics offer unmatched advantages in safety and efficiency. For South Africa’s maritime ambitions, embracing these cables paves the way for sustainable, resilient infrastructure. As the industry evolves, their role will only grow, safeguarding lives and assets on the high seas.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430