Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV HEPR Insulated, LSOH (SHF1) Sheathed, Screened Flame Retardant Power & Control Cables (Single Core)

Application | These cables are used for fixed installations on ships and offshore units in all locations and on open deck. The good screening qualities of the copper braid also reduce radio interference and electrical influences to electronics installations. These cables are flame retardant, low smoke & halogen free. |

Standards | DIN 89160/98 |

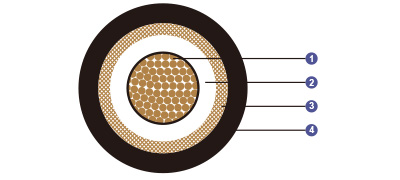

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | HEPR. |

Overall Screen | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Single core: Natural colour (beige). |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

M092-0.6/1KV-1G7MH-R-1C4 | 1×4 | 0.7 | 1.2 | 7.3 | 110 |

M092-0.6/1KV-1G7MH-R-1C6 | 1×6 | 0.7 | 1.2 | 8.3 | 140 |

M092-0.6/1KV-1G7MH-R-1C10 | 1×10 | 0.7 | 1.2 | 9.3 | 190 |

M092-0.6/1KV-1G7MH-R-1C16 | 1×16 | 0.7 | 1.2 | 10.3 | 270 |

M092-0.6/1KV-1G7MH-R-1C25 | 1×25 | 0.9 | 1.2 | 12.3 | 380 |

M092-0.6/1KV-1G7MH-R-1C35 | 1×35 | 0.9 | 1.2 | 13.3 | 480 |

M092-0.6/1KV-1G7MH-R-1C50 | 1×50 | 1.0 | 1.3 | 15.3 | 660 |

M092-0.6/1KV-1G7MH-R-1C70 | 1×70 | 1.1 | 1.4 | 17.3 | 900 |

M092-0.6/1KV-1G7MH-R-1C95 | 1×95 | 1.1 | 1.4 | 19.5 | 1170 |

M092-0.6/1KV-1G7MH-R-1C120 | 1×120 | 1.2 | 1.5 | 21.0 | 1410 |

M092-0.6/1KV-1G7MH-R-1C150 | 1×150 | 1.4 | 1.6 | 22.8 | 1750 |

M092-0.6/1KV-1G7MH-R-1C185 | 1×185 | 1.6 | 1.6 | 24.8 | 2160 |

M092-0.6/1KV-1G7MH-R-1C240 | 1×240 | 1.7 | 1.7 | 27.8 | 2770 |

M092-0.6/1KV-1G7MH-R-1C300 | 1×300 | 1.8 | 1.8 | 30.3 | 3440 |

Introduction

In the demanding environment of marine and offshore installations, the choice of cabling is critical to ensuring safety, reliability, and operational efficiency. The 0.6/1 kV HEPR insulated, low smoke zero halogen (LSOH) sheathed, screened flame retardant power and control cables (single core) are engineered to meet the stringent requirements of ships and offshore units. These cables, compliant with international standards such as DIN 89160/98 and IEC 60092-353, offer exceptional performance in harsh conditions, including open deck installations. This article provides a comprehensive analysis of their construction, characteristics, and advantages, with a focus on their relevance in South African maritime applications.

Standards and Compliance

These cables adhere to a suite of international standards, ensuring their suitability for marine and offshore applications:

DIN 89160/98: Specifies requirements for power cables in marine environments.

IEC 60092-353: Governs the design and testing of power cables for ships and offshore units.

IEC 60332-1 and IEC 60332-3-22: Ensure flame retardancy, critical for fire safety.

IEC 60754-1/2: Confirm the absence of halogen emissions, reducing toxicity risks.

IEC 61034: Verify low smoke emission, enhancing visibility during emergencies.

Compliance with these standards ensures that the cables meet global benchmarks for safety and performance, making them a trusted choice for South African shipbuilders and offshore operators.

Advantages in Marine Applications

The 0.6/1 kV HEPR insulated, LSOH sheathed, screened cables offer several advantages that make them indispensable in marine and offshore settings:

1. Enhanced Fire Safety

The LSOH sheath and flame-retardant properties significantly reduce fire hazards. In a fire, the cables produce minimal smoke and no halogen gases, which is critical in enclosed environments like ships. For example, in South Africa’s busy ports like Durban and Cape Town, where vessels are frequently docked, these cables ensure compliance with stringent safety regulations, protecting both crew and cargo.

2. Electromagnetic Interference Protection

The copper braid screen minimizes electromagnetic interference, ensuring the reliable operation of sensitive equipment such as radar, GPS, and communication systems. This is particularly relevant for South African fishing vessels operating in the Southern Ocean, where precise navigation is essential for safety and efficiency.

3. Durability in Harsh Environments

The HEPR insulation and LSOH sheath provide resistance to moisture, UV radiation, and temperature extremes, making these cables ideal for open deck installations. In South Africa’s offshore oil and gas sector, particularly in the Mossel Bay fields, these cables withstand the corrosive effects of saltwater and harsh weather conditions.

4. Compliance with International Standards

Adherence to IEC and DIN standards ensures global acceptance, facilitating the export of South African-built vessels to international markets. This is a significant advantage for shipyards in Cape Town, which compete in the global maritime industry.

5. Versatility

Available in a wide range of sizes, these cables cater to diverse applications, from powering critical systems to controlling auxiliary equipment. Their flexibility and compact design make them suitable for retrofitting older vessels, a common practice in South Africa’s maritime refurbishment industry.

Conclusion

The 0.6/1 kV HEPR insulated, LSOH (SHF1) sheathed, screened flame retardant power and control cables represent a pinnacle of engineering for marine and offshore applications. Their robust construction, compliance with international standards, and advanced safety features make them an ideal choice for South African maritime operations. From the busy ports of Durban to the offshore platforms of Mossel Bay, these cables ensure reliability, safety, and efficiency in the harshest environments. As the industry evolves, these cables will continue to play a vital role in supporting South Africa’s maritime ambitions, both domestically and on the global stage.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430