Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed, Armoured Flame Retardant Power & Control Cables (Multicore)

Application | These armoured cables are used on board of ships in all locations for fixed installations where cable protection is required. These cables are flame retardant, low smoke & halogen free. |

Standards | IEC 60092-350/351/353/359 |

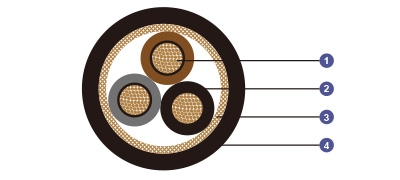

Construction | |

Conductors | Class 2 stranded copper conductor, round or sector shaped. Class 5 stranded conductors can be offered upon request. |

Insulation | XLPE |

Inner Covering | Lapping |

Armour | Copper wire braid |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request |

Core Identification | Two cores: Blue, Brown. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Multicore Armoured 0.6/1kV (-R stands for class 2 conductor. For class 5 conductor, please change –R to –F)

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

2C1.5 | 2×1.5 | 0.7 | 1.1 | 9.3 | 120 |

2C2.5 | 2×2.5 | 0.7 | 1.1 | 10.1 | 150 |

2C4 | 2×4 | 0.9 | 1.2 | 12.2 | 195 |

2C6 | 2×6 | 0.9 | 1.2 | 13.7 | 275 |

2C10 | 2×10 | 0.9 | 1.3 | 15.7 | 385 |

2C16 | 2×16 | 0.9 | 1.4 | 18.4 | 595 |

2C25 | 2×25 | 0.9 | 1.5 | 21.3 | 820 |

2C35 | 2×35 | 0.9 | 1.5 | 23.9 | 1140 |

2C50 | 2×50 | 1.0 | 1.5 | 26.7 | 1500 |

3C1.5(3G1.5) | 3×(G)1.5 | 0.7 | 1.1 | 9.8 | 145 |

3C2.5(3G2.5) | 3×(G)2.5 | 0.7 | 1.1 | 10.7 | 180 |

3C4 | 3×4 | 0.9 | 1.2 | 12.9 | 245 |

3C6 | 3×6 | 0.9 | 1.3 | 14.7 | 345 |

3C10 | 3×10 | 0.9 | 1.3 | 16.6 | 490 |

3C16 | 3×16 | 0.9 | 1.4 | 19.5 | 755 |

3C25 | 3×25 | 0.9 | 1.6 | 22.7 | 1095 |

3C35 | 3×35 | 0.9 | 1.6 | 24.9 | 1340 |

3C35S | 3×35 (sector shaped) | 0.9 | 1.6 | 22.0 | 1320 |

3C50 | 3×50 | 1.0 | 1.6 | 27.1 | 1750 |

3C50S | 3×50 (sector shaped) | 1.0 | 1.6 | 24.8 | 1820 |

3C70S | 3×70 (sector shaped) | 1.1 | 2.0 | 29.7 | 2575 |

3C95S | 3×95 (sector shaped) | 1.1 | 2.1 | 33.1 | 3435 |

3C120S | 3×120 (sector shaped) | 1.2 | 2.2 | 36.0 | 4070 |

3C150S | 3×150 (sector shaped) | 1.4 | 2.4 | 40.9 | 5435 |

4C1.5(4G1.5) | 4×(G)1.5 | 0.7 | 1.1 | 10.5 | 170 |

4C2.5(4G2.5) | 4×(G)2.5 | 0.7 | 1.2 | 11.8 | 225 |

4C4 | 4×4 | 0.9 | 1.3 | 14.7 | 335 |

4C6 | 4×6 | 0.9 | 1.3 | 16.0 | 425 |

4C10 | 4×10 | 0.9 | 1.4 | 18.3 | 625 |

4C16 | 4×16 | 0.9 | 1.5 | 21.5 | 935 |

4C25 | 4×25 | 0.9 | 1.6 | 24.4 | 1345 |

4C35 | 4×35 | 0.9 | 1.7 | 27.5 | 1715 |

4C35S | 4×35 (sector shaped) | 0.9 | 1.7 | 24.3 | 1700 |

4C50 | 4×50 | 1.0 | 1.6 | 29.9 | 2400 |

4C50S | 4×50(sector shaped) | 1.0 | 1.6 | 27.3 | 2300 |

4C70S | 4×70(sector shaped) | 1.1 | 2.1 | 32.8 | 3250 |

4C95S | 4×95(sector shaped) | 1.1 | 2.2 | 37.3 | 4390 |

5C1.5(5G1.5) | 5×(G)1.5 | 0.7 | 1.2 | 11.7 | 205 |

5C2.5(5G2.5) | 5×(G)2.5 | 0.7 | 1.2 | 12.8 | 265 |

5G4 | 5G4 | 0.9 | 1.2 | 15.2 | 360 |

6C1.5 | 6×1.5 | 0.7 | 1.2 | 12.7 | 240 |

7C1.5 | 7×1.5 | 0.7 | 1.2 | 12.7 | 260 |

8C1.5 | 8×1.5 | 0.7 | 1.2 | 15.5 | 340 |

10C1.5 | 10×1.5 | 0.7 | 1.3 | 16.2 | 390 |

12C1.5 | 12×1.5 | 0.7 | 1.4 | 16.9 | 440 |

16C1.5 | 16×1.5 | 0.7 | 1.4 | 18.6 | 550 |

19C1.5 | 19×1.5 | 0.7 | 1.5 | 19.7 | 620 |

24C1.5 | 24×1.5 | 0.7 | 1.6 | 22.9 | 800 |

5C2.5 | 5×2.5 | 0.7 | 1.2 | 12.9 | 290 |

7C2.5 | 7×2.5 | 0.7 | 1.2 | 14.6 | 390 |

12C2.5 | 12×2.5 | 0.7 | 1.4 | 18.7 | 610 |

19C2.5 | 19×2.5 | 0.7 | 1.5 | 21.8 | 870 |

24C2.5 | 24×2.5 | 0.7 | 1.6 | 25.6 | 1100 |

27C2.5 | 27×2.5 | 0.7 | 1.7 | 26.1 | 1200 |

37C2.5 | 37×2.5 | 0.7 | 1.9 | 29.2 | 1560 |

Introduction

In the realm of marine engineering, the reliability and safety of electrical systems are paramount. Ships operate in harsh environments where exposure to moisture, mechanical stress, and potential fire hazards demands robust cabling solutions. Among the most advanced options available are the 0.6/1 kV XLPE insulated, LSOH (SHF1) sheathed armoured flame retardant multicore power and control cables. These cables, designed specifically for fixed installations on board ships, embody a fusion of cutting-edge materials science and electrical engineering principles. They provide not only efficient power transmission but also enhanced protection against environmental and operational risks.

Compliance with International Standards

Adherence to rigorous standards is non-negotiable in marine cabling, and these 0.6/1 kV XLPE insulated, LSOH (SHF1) sheathed armoured flame retardant multicore cables excel in this regard. They comply with IEC 60092 series, which governs electrical installations in ships. Specifically, IEC 60092-350 covers general construction, IEC 60092-351 addresses insulating materials, IEC 60092-353 deals with power cables, and IEC 60092-359 specifies sheathing materials.

Flame retardancy is verified through IEC 60332-1 for single cable tests and IEC 60332-3-22 for bunched cables, ensuring they do not propagate fire in vertical installations—a critical factor in confined ship spaces. Low smoke and halogen-free properties are tested under IEC 60754-1/2 for halogen acid gas emission and IEC 61034 for smoke density, minimising toxicity and visibility obstruction during fires. These standards are particularly relevant in South Africa, where the South African Bureau of Standards (SABS) often harmonises with IEC norms to facilitate international trade in maritime equipment.

By meeting these benchmarks, the cables contribute to safer evacuations and reduced environmental harm, aligning with global initiatives like the International Maritime Organization's (IMO) SOLAS conventions. In South African contexts, such compliance supports the country's ratification of these treaties, ensuring vessels like those operated by Transnet National Ports Authority adhere to best practices.

Applications in Marine Environments

These armoured cables find extensive use in shipboard fixed installations where protection is essential. On vessels, they power lighting systems, control circuits, propulsion motors, and auxiliary equipment. Their flame retardant and low smoke characteristics make them ideal for engine rooms, accommodation areas, and cargo holds, where fire risks are elevated due to fuel proximity or electrical overloads.

In South Africa, the maritime sector benefits significantly from these cables. For instance, in the retrofit of older vessels at the Durban Ship Repair Yard, these multicore cables have been employed to upgrade electrical systems, enhancing safety amid the port's high traffic of container ships and tankers. A notable case study involves the MSC Oscar, a massive container ship that docked in Durban for maintenance in 2023. Engineers replaced outdated PVC-insulated cables with XLPE variants to comply with updated IMO fire safety codes, reducing the risk of halogen-induced corrosion on sensitive electronics.

Another example is the use in offshore support vessels servicing South Africa's oil and gas fields off the Mossel Bay coast. Here, the armoured design protects against mechanical damage from waves and equipment handling, while the LSOH sheath ensures minimal smoke in the event of a fire, aiding crew evacuation in confined platforms.

Beyond ships, these cables are adaptable for fixed offshore installations, such as wind farms in the Agulhas Current region, where South Africa's renewable energy push is gaining momentum. Their multicore configuration allows for efficient bundling of power and control signals, streamlining installations in space-limited turbine nacelles.

Advantages Over Conventional Cables

The advantages of these cables are multifaceted, starting with enhanced safety. The flame retardant property, combined with LSOH sheathing, significantly reduces fire spread and toxic emissions. In a fire scenario, halogen-free materials avoid releasing corrosive gases that could damage equipment or harm personnel, a stark improvement over PVC cables.

Durability is another edge; the armoured braid offers superior mechanical protection, extending service life in vibration-prone marine settings. This translates to lower maintenance costs, as seen in South African fishing fleets where cable failures from abrasion are common.

Environmentally, the halogen-free composition aligns with South Africa's commitments under the Stockholm Convention on persistent organic pollutants. In terms of performance, XLPE insulation provides better electrical efficiency, with lower capacitance and higher current ratings, enabling longer runs without voltage drop issues.

Economically, while initial costs may be higher, the long-term savings from reduced downtime and compliance with standards like IEC make them cost-effective. A study by the South African Maritime Safety Authority (SAMSA) on vessel incidents highlighted that upgraded cabling reduced electrical fires by 40% in monitored ships.

Conclusion

The 0.6/1 kV XLPE insulated, LSOH (SHF1) sheathed armoured flame retardant multicore power and control cables represent a pinnacle of marine electrical innovation. Their sophisticated construction, stringent standard compliance, and superior properties make them indispensable for safe, efficient ship operations. In South Africa, where maritime trade drives economic growth, adopting such technologies not only enhances vessel reliability but also aligns with global sustainability goals.

As the industry evolves, these cables will likely see further enhancements, such as integrated fibre optics for data transmission. For professionals in the field, understanding their intricacies offers valuable insights into building resilient electrical systems. Ultimately, investing in these cables is an investment in safety, performance, and the future of marine engineering.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430