Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed, Armoured Flame Retardant Power & Control Cables (Single Core)

Application | These armoured cables are used on board of ships in all locations for fixed installations where cable protection is required. These cables are flame retardant, low smoke & halogen free. |

Standards | IEC 60092-350/351/353/359 |

Construction | |

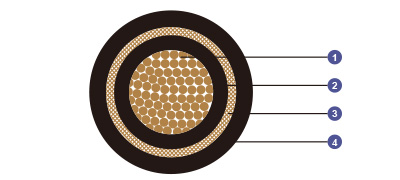

Conductors | Class 2 stranded copper conductor, round or sector shaped. Class 5 stranded conductors can be offered upon request. |

Insulation | XLPE |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Single core: Black. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Single Core Armoured 0.6/1kV (-R stands for class 2 conductor. For class 5 conductor, please change –R to –F)

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

1C1.5 | 1×1.5 | 0.7 | 1.1 | 6.3 | 70 |

1C2.5 | 1×2.5 | 0.7 | 1.1 | 6.7 | 80 |

1C4 | 1×4 | 0.9 | 1.1 | 7.4 | 100 |

1C6 | 1×6 | 0.9 | 1.1 | 8.0 | 120 |

1C10 | 1×10 | 0.9 | 1.1 | 8.8 | 180 |

1C16 | 1×16 | 0.9 | 1.1 | 10.2 | 245 |

1C25 | 1×25 | 0.9 | 1.2 | 11.7 | 355 |

1C35 | 1×35 | 0.9 | 1.2 | 13.0 | 455 |

1C50 | 1×50 | 1.0 | 1.3 | 15.0 | 620 |

1C70 | 1×70 | 1.1 | 1.4 | 17.2 | 850 |

1C95 | 1×95 | 1.1 | 1.4 | 19.1 | 1115 |

1C120 | 1×120 | 1.2 | 1.5 | 21.1 | 1385 |

1C150 | 1×150 | 1.4 | 1.6 | 23.2 | 1690 |

1C185 | 1×185 | 1.6 | 1.6 | 25.5 | 2065 |

1C240 | 1×240 | 1.7 | 1.7 | 28.4 | 2640 |

1C300 | 1×300 | 1.8 | 1.8 | 31.3 | 3260 |

Introduction

In the demanding environment of maritime operations, the reliability and safety of electrical systems are paramount. Ships, offshore platforms, and marine installations require robust cabling solutions that can withstand harsh conditions while ensuring safety and performance. The 0.6/1 kV XLPE insulated, low smoke zero halogen (LSOH) sheathed, armoured flame retardant power and control cables (single core) are engineered to meet these challenges. Widely used in fixed installations on board ships, these cables combine advanced materials and construction techniques to deliver exceptional performance.

Compliance with International Standards

These cables adhere to stringent international standards, ensuring their suitability for marine applications. The relevant standards include:

IEC 60092-350/351/353/359: These standards govern the design, construction, and testing of electrical installations in ships, ensuring safety and reliability.

IEC 60332-1 and IEC 60332-3-22: These standards confirm the cables’ flame retardant properties, ensuring they resist fire propagation.

IEC 60754-1/2: These standards verify that the cables are halogen-free, minimizing toxic gas emissions during combustion.

IEC 61034: This standard ensures low smoke emission, enhancing visibility and safety in fire scenarios.

Key Characteristics and Technical Specifications

The 0.6/1 kV single-core armoured cables are available in a range of cross-sectional sizes, from 1.5 mm² to 300 mm², catering to various power and control requirements. Below is a summary of their technical specifications:

Bending Radius: 6 × overall diameter (OD), ensuring flexibility during installation without compromising structural integrity.

Temperature Range: -30°C to +80°C, suitable for extreme marine environments.

Nominal Insulation Thickness: Ranges from 0.7 mm to 1.8 mm, depending on the conductor size.

Nominal Sheath Thickness: Ranges from 1.1 mm to 1.8 mm, providing robust protection.

Nominal Overall Diameter: Varies from 6.3 mm (1.5 mm²) to 31.3 mm (300 mm²).

Nominal Weight: Ranges from 70 kg/km (1.5 mm²) to 3260 kg/km (300 mm²), reflecting the cables’ robust construction.

Advantages of 0.6/1 kV XLPE Insulated, LSOH Sheathed Cables

The unique combination of materials and design in these cables offers several advantages, particularly in marine applications.

Flame Retardancy

The cables’ compliance with IEC 60332-1 and IEC 60332-3-22 ensures they resist fire propagation. In the confined spaces of a ship, this is critical to preventing the spread of fire, protecting both personnel and equipment.

Low Smoke and Halogen-Free Properties

The LSOH sheath (SHF1 or SHF2) minimizes smoke emission and eliminates toxic halogen gases in fire scenarios. This enhances visibility and reduces health risks, making these cables ideal for densely populated areas like crew quarters and control rooms.

Mechanical Protection

The copper wire braid armour provides robust protection against mechanical damage. In marine environments, where cables are subject to vibrations, impacts, and abrasions, this armour ensures long-term reliability.

Thermal and Environmental Resilience

The XLPE insulation and LSOH sheath enable the cables to operate effectively in a wide temperature range (-30°C to +80°C). This is particularly important in South African waters, where vessels may encounter both scorching summer heat and cold winter conditions.

High Electrical Performance

The use of high-quality copper conductors and XLPE insulation ensures low electrical resistance and high dielectric strength, resulting in efficient power transmission and minimal energy loss.

Versatility

With a range of conductor sizes and the option for Class 5 conductors, these cables can be tailored to various applications, from powering navigation systems to controlling machinery.

Applications in South African Maritime Contexts

South Africa’s maritime industry, encompassing ports like Durban, Cape Town, and Richards Bay, relies on robust electrical systems to support shipping, offshore oil and gas exploration, and renewable energy projects. The 0.6/1 kV XLPE insulated, LSOH sheathed, armoured cables are well-suited to these applications.

Case Study: Port of Durban

The Port of Durban, one of Africa’s busiest ports, handles a significant volume of cargo and passenger vessels. Electrical systems on these vessels must comply with international safety standards while withstanding the humid, corrosive coastal environment. The flame retardant and LSOH properties of these cables make them ideal for use in engine rooms, control panels, and lighting systems, where safety is paramount. Their armoured construction protects against mechanical damage during cargo handling operations, ensuring uninterrupted power supply.

Installation and Maintenance Considerations

Proper installation and maintenance are critical to maximizing the performance and lifespan of these cables. Key considerations include:

Bending Radius: Adhering to the 6 × OD bending radius prevents damage to the insulation and conductors during installation.

Environmental Protection: While the cables are designed for harsh environments, installers should avoid prolonged exposure to direct sunlight or chemicals, which could degrade the LSOH sheath over time.

Regular Inspections: Periodic checks for signs of wear, corrosion, or mechanical damage can prevent failures, particularly in high-vibration areas like engine rooms.

Compliance with Standards: Installations must comply with IEC 60092 standards to ensure safety and performance.

Conclusion

The 0.6/1 kV XLPE insulated, LSOH sheathed, armoured flame retardant power and control cables are a cornerstone of modern marine electrical systems. Their robust construction, compliance with international standards, and advanced safety features make them ideal for the demanding conditions of maritime environments. In South Africa, these cables support critical applications in ports, offshore energy projects, and fishing vessels, contributing to safety, reliability, and efficiency. As the maritime industry evolves, these cables will continue to play a vital role, with ongoing innovations enhancing their performance and sustainability.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430