Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Multicore)

Application | These unarmoured power & control cables are used on board of ships in all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352. |

Standards | IEC 60092-350/351/353/359 |

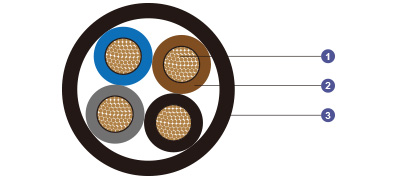

Construction | |

Conductors | Class 2 stranded copper conductor, round or sector shaped. Class 5 stranded conductors can be offered upon request. |

Insulation | XLPE. |

Filler (optional) | Halogen free filling compound. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Two cores: Blue, Brown. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD (OD>25mm); 4×OD (OD ≤25mm) |

Dimensions and Weight

MTX400 1RZ1-R Multicore 0.6/1kV (-R stands for class 2 conductor. For class 5 conductor, please change –R to –F)

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

MTX400-1RZ1-R-2C1.5 | 2×1.5 | 0.7 | 1.1 | 8.4 | 80 |

MTX400-1RZ1-R-2C2.5 | 2×2.5 | 0.7 | 1.1 | 9.2 | 100 |

MTX400-1RZ1-R-2C4 | 2×4 | 0.9 | 1.1 | 11.1 | 135 |

MTX400-1RZ1-R-2C6 | 2×6 | 0.9 | 1.2 | 12.4 | 185 |

MTX400-1RZ1-R-2C10 | 2×10 | 0.9 | 1.2 | 14.1 | 270 |

MTX400-1RZ1-R-2C16 | 2×16 | 0.9 | 1.3 | 16.4 | 400 |

MTX400-1RZ1-R-2C25 | 2×25 | 0.9 | 1.3 | 18.8 | 700 |

MTX400-1RZ1-R-2C35 | 2×35 | 0.9 | 1.3 | 21.4 | 930 |

MTX400-1RZ1-R-2C50 | 2×50 | 1.0 | 1.3 | 24.2 | 1290 |

MTX400-1RZ1-R-3C1.5(3G1.5) | 3×(G)1.5 | 0.7 | 1.1 | 8.8 | 100 |

MTX400-1RZ1-R-3C2.5(3G2.5) | 3×(G)2.5 | 0.7 | 1.1 | 9.8 | 130 |

MTX400-1RZ1-R-3C4(3G4) | 3×(G)4 | 0.9 | 1.2 | 12.0 | 190 |

MTX400-1RZ1-R-3C6(3G6) | 3×(G)6 | 0.9 | 1.2 | 13.2 | 250 |

MTX400-1RZ1-R-3C10 | 3×10 | 0.9 | 1.3 | 15.2 | 380 |

MTX400-1RZ1-R-3C16(3G16) | 3×16 | 0.9 | 1.3 | 17.5 | 560 |

MTX400-1RZ1-R-3C25 | 3×25 | 0.9 | 1.5 | 20.7 | 875 |

MTX400-1RZ1-R-3C35 | 3×35 | 0.9 | 1.6 | 23.5 | 1220 |

MTX400-1RZ1-R-3C35S | 3×35 (sector shaped) | 0.9 | 1.5 | 20.1 | 1135 |

MTX400-1RZ1-R-3C50 | 3×50 | 1.0 | 1.7 | 26.7 | 1780 |

MTX400-1RZ1-R-3C50S | 3×50 (sector shaped) | 1.0 | 1.7 | 22.8 | 1530 |

MTX400-1RZ1-R-3C70S | 3×70 (sector shaped) | 1.1 | 1.8 | 26.7 | 2150 |

MTX400-1RZ1-R-3C95S | 3×95 (sector shaped) | 1.1 | 1.9 | 30.2 | 2900 |

MTX400-1RZ1-R-3C120S | 3×120 (sector shaped) | 1.2 | 2.1 | 34.0 | 3675 |

MTX400-1RZ1-R-4C1.5(4G1.5) | 4×(G)1.5 | 0.7 | 1.1 | 9.6 | 120 |

MTX400-1RZ1-R-4C2.5(4G2.5) | 4×(G)2.5 | 0.7 | 1.1 | 10.7 | 165 |

MTX400-1RZ1-R-4C4(4G4) | 4×(G)4 | 0.9 | 1.2 | 13.2 | 240 |

MTX400-1RZ1-R-4C6(4G6) | 4×(G)6 | 0.9 | 1.2 | 14.5 | 320 |

MTX400-1RZ1-R-4C10(4G10) | 4×(G)10 | 0.9 | 1.3 | 16.7 | 490 |

MTX400-1RZ1-R-4C16(4G16) | 4×(G)16 | 0.9 | 1.4 | 19.5 | 740 |

MTX400-1RZ1-R-4C25(4G25) | 4×(G)25 | 0.9 | 1.5 | 22.8 | 1145 |

MTX400-1RZ1-R-4G35 | 4G35 | 0.9 | 1.7 | 26.0 | 1515 |

MTX400-1RZ1-R-4G50 | 4G50 | 1.0 | 1.8 | 29.7 | 2340 |

MTX400-1RZ1-R-5C1.5(5G1.5) | 5×(G)1.5 | 0.7 | 1.1 | 10.5 | 145 |

MTX400-1RZ1-R-5C2.5(5G2.5) | 5×(G)2.5 | 0.7 | 1.2 | 11.9 | 205 |

MTX400-1RZ1-R-5G6 | 5G6 | 0.9 | 1.3 | 16.1 | 400 |

MTX400-1RZ1-R-5G16 | 5G16 | 0.9 | 1.5 | 21.6 | 920 |

MTX400-1RZ1-R-6C1.5 | 6×1.5 | 0.7 | 1.2 | 11.6 | 180 |

MTX400-1RZ1-R-7C1.5 | 7×1.5 | 0.7 | 1.2 | 11.7 | 195 |

MTX400-1RZ1-R-8C1.5(8G1.5) | 8×(G)1.5 | 0.7 | 1.2 | 12.7 | 225 |

MTX400-1RZ1-R-10C1.5 | 10×1.5 | 0.7 | 1.3 | 14.8 | 275 |

MTX400-1RZ1-R-12C1.5 | 12×1.5 | 0.7 | 1.3 | 15.3 | 315 |

MTX400-1RZ1-R-16C1.5 | 16×1.5 | 0.7 | 1.4 | 17.2 | 410 |

MTX400-1RZ1-R-19C1.5 | 19×1.5 | 0.7 | 1.4 | 18.1 | 470 |

MTX400-1RZ1-R-24C1.5 | 24×1.5 | 0.7 | 1.5 | 21.3 | 620 |

MTX400-1RZ1-R-5C2.5 | 5×2.5 | 0.7 | 1.2 | 11.9 | 210 |

MTX400-1RZ1-R-7C2.5 | 7×2.5 | 0.7 | 1.2 | 13.2 | 280 |

MTX400-1RZ1-R-12C2.5 | 12×2.5 | 0.7 | 1.3 | 17.4 | 460 |

MTX400-1RZ1-R-19C2.5 | 19×2.5 | 0.7 | 1.4 | 20.6 | 690 |

MTX400-1RZ1-R-24C2.5 | 24×2.5 | 0.7 | 1.5 | 24.3 | 880 |

MTX400-1RZ1-R-27C2.5 | 27×2.5 | 0.7 | 1.5 | 24.6 | 970 |

MTX400-1RZ1-R-37C2.5 | 37×2.5 | 0.7 | 1.6 | 27.7 | 1300 |

Introduction

In the demanding world of maritime engineering, where reliability and safety are paramount, the choice of electrical cabling can make the difference between seamless operations and catastrophic failures. The 0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Multicore) represent a pinnacle of modern cable technology tailored for shipboard installations. These unarmoured cables are specifically designed for fixed installations on vessels, ensuring compliance with rigorous international standards while prioritising flame retardancy, low smoke emission, and halogen-free properties.

South Africa's maritime sector, encompassing bustling ports like Durban and Cape Town, relies heavily on such advanced cabling to support its growing shipbuilding, repair, and offshore industries. With the country's extensive coastline and increasing involvement in international shipping routes, the adoption of these cables aligns with global safety trends and local regulatory demands.

Applications in Maritime Environments

These 0.6/1 kV XLPE Insulated LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables are primarily utilised on board ships for fixed installations in locations not exposed to mechanical risks. According to industry specifications, they comply with IEC 60092-352, making them ideal for powering essential systems such as lighting, machinery controls, and communication networks. Their unarmoured design suits internal ship compartments where armouring might add unnecessary weight or bulk, yet protection from fire and environmental factors is crucial.

In marine applications, these cables excel in environments prone to humidity, salt exposure, and temperature fluctuations. For instance, on cargo vessels navigating South African waters, they ensure reliable power distribution to navigation systems and cargo handling equipment. The flame retardant nature prevents fire propagation, while low smoke and halogen-free emissions facilitate safer evacuations during emergencies. This is particularly relevant in passenger ships or ferries operating along the Cape Route, where passenger safety is non-negotiable.

Moreover, their versatility extends to offshore platforms and mobile units, where fixed wiring must withstand vibrations and corrosive sea air without compromising performance. In South Africa, with its expanding offshore oil and gas sector off the coast of Mossel Bay, these cables support control systems that monitor drilling operations, highlighting their role in enhancing operational resilience.

Compliance with International Standards

Adherence to standards is the backbone of marine cable reliability. These cables meet a suite of IEC specifications, including IEC 60092-350, which covers general construction and test requirements for shipboard cables; IEC 60092-351 for insulating materials; IEC 60092-353 for single and multicore non-radial field power cables with extruded solid insulation; and IEC 60092-359 for sheathing materials. These standards ensure the cables are suitable for electrical installations on ships and offshore units, incorporating good practice and alignments with broader maritime safety protocols.

Flame retardancy is verified through IEC 60332-1 for single cable flame tests and IEC 60332-3-22 for bunched cable fire propagation tests, confirming the cables do not spread flames vertically or horizontally. Low smoke emission complies with IEC 61034, measuring smoke density to ensure visibility during fires, while halogen-free properties are tested under IEC 60754-1/2, limiting acid gas evolution to prevent corrosion and health risks. In South African contexts, these align with local maritime authority requirements, such as those from the South African Maritime Safety Authority (SAMSA), which emphasise international compliance for vessels registered under the South African flag.

This rigorous standardisation not only guarantees performance but also facilitates global trade, as ships built or repaired in South African yards can meet export criteria for European or Asian markets.

In-Depth Analysis of Characteristics

Delving deeper, the XLPE insulation stands out for its cross-linked structure, which prevents melting even at high temperatures, unlike thermoplastic alternatives. This results in a higher continuous operating temperature of 90°C and short-circuit tolerance up to 250°C, enhancing reliability in overloaded conditions common on ships.

The LSOH (SHF1) sheath, a halogen-free polyolefin compound, minimises toxic gas release, with acidity levels below 5% as per IEC 60754-2. In marine fires, this characteristic is crucial, as halogens from PVC can form hydrochloric acid, corroding equipment and harming crew.

Flame retardancy, achieved through additives in the sheath, ensures self-extinguishing properties, tested to IEC 60332-3-22 where cables withstand a 40-minute flame without propagating fire beyond 2.5 metres. Low smoke density, under IEC 61034, maintains transmittance above 60%, aiding visibility in smoke-filled compartments.

Electrically, the 0.6/1 kV rating supports low-voltage power and control applications, with low dielectric constant reducing power losses. Mechanically, the cables resist abrasion and chemicals, vital in salty marine air.

Advantages in Marine Environments

The advantages of these cables are multifaceted. Safety is foremost: in a fire, LSOH sheathing reduces smoke to levels that preserve escape routes, potentially saving lives on vessels like South African ferries. Halogen-free composition prevents acid formation, protecting sensitive electronics and reducing post-fire cleanup costs.

XLPE insulation provides superior moisture resistance, preventing water treeing—a common failure in humid environments—and extending cable lifespan to over 30 years. This hydrophobic quality is advantageous in South Africa's rainy coastal regions.

Efficiency gains include lighter weight due to unarmoured design, lowering ship fuel consumption, and higher current ratings allowing smaller cross-sections for the same load, saving space. Environmentally, halogen-free materials align with sustainable practices, reducing ecological impact during disposal.

In comparison to PVC cables, these offer better ageing resistance, with XLPE maintaining properties under UV and thermal stress. For marine control systems, multicore configurations streamline wiring, reducing installation time and errors.

Conclusion

The 0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Multicore) embody innovation in marine electrical engineering. Their robust construction, compliance with IEC standards, and superior characteristics—flame retardancy, low smoke, and halogen-free—offer unparalleled advantages in safety, efficiency, and longevity. In South Africa, where the maritime industry drives trade and employment, adopting such technology is not just beneficial but essential. As global shipping evolves towards sustainability and resilience, these cables will undoubtedly play a central role, ensuring vessels navigate the seas with confidence.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430