Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

0.6/1 kV XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Power & Control Cables (Single Core)

Application | These unarmoured power & control cables are used on board of ships in all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352. These cables are flame retardant, low smoke & halogen free. |

Standards | IEC 60092-350/351/353/359 |

Construction | |

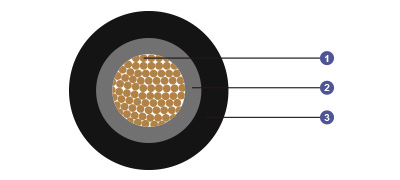

Conductors | Class 2 stranded copper conductor, round or sector shaped. Class 5 stranded conductors can be offered upon request. |

Insulation | XLPE. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Single core: Black |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD (OD>25mm); 4×OD (OD ≤25mm) |

Dimensions and Weight

Single Core 0.6/1kV (-R stands for class 2 conductor. For class 5 conductor, please change –R to –F)

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

1C1.5 | 1×1.5 | 0.7 | 1.0 | 5.0 | 40 |

1C2.5 | 1×2.5 | 0.7 | 1.0 | 5.4 | 50 |

1C4 | 1×4 | 0.9 | 1.04 | 6.4 | 70 |

1C6 | 1×6 | 0.9 | 1.04 | 7.0 | 90 |

1C10 | 1×10 | 0.9 | 1.04 | 7.9 | 130 |

1C16 | 1×16 | 0.9 | 1.04 | 8.9 | 190 |

1C25 | 1×25 | 0.9 | 1.1 | 10.4 | 295 |

1C35 | 1×35 | 0.9 | 1.1 | 11.7 | 380 |

1C50 | 1×50 | 1.0 | 1.2 | 13.3 | 510 |

1C70 | 1×70 | 1.1 | 1.3 | 15.5 | 720 |

1C95 | 1×95 | 1.1 | 1.3 | 17.4 | 970 |

1C120 | 1×120 | 1.2 | 1.4 | 19.4 | 1220 |

1C150 | 1×150 | 1.4 | 1.5 | 21.5 | 1505 |

1C185 | 1×185 | 1.6 | 1.5 | 23.8 | 1865 |

1C240 | 1×240 | 1.7 | 1.6 | 26.7 | 2420 |

1C300 | 1×300 | 1.8 | 1.7 | 29.6 | 3015 |

Introduction

In the demanding world of maritime engineering, where safety, reliability, and environmental compliance are paramount, the choice of electrical cabling plays a critical role. Unarmoured power and control cables, specifically those rated at 0.6/1 kV with cross-linked polyethylene (XLPE) insulation and low smoke zero halogen (LSOH) sheathing, have emerged as a cornerstone for fixed installations on ships and offshore platforms. These cables are designed for environments not prone to mechanical stress, ensuring seamless power transmission and control in confined, high-risk spaces. Compliant with international standards such as IEC 60092-352, they are flame retardant, emit minimal smoke, and are free from halogens, making them ideal for marine use where fire hazards can escalate rapidly.

The maritime industry in South Africa, with its extensive coastline and bustling ports like Durban and Cape Town, relies heavily on such advanced cabling solutions. South Africa's shipbuilding and repair sector, though modest compared to global giants, supports vital operations in fishing, offshore oil exploration, and cargo shipping. For instance, vessels operating in the Agulhas Current or servicing the Mossel Bay gas fields demand cables that withstand harsh oceanic conditions while prioritising crew safety. XLPE insulation provides superior thermal and electrical properties, while LSOH sheathing ensures low toxicity in fires, aligning with global trends towards sustainable and safer marine infrastructure.

Standards and Compliance

Compliance with international standards is the bedrock of marine cable reliability, ensuring they perform under extreme conditions without compromising safety. The 0.6/1 kV XLPE insulated, LSOH sheathed flame retardant cables adhere to a suite of IEC standards, specifically IEC 60092-350, 351, 353, and 359, which govern electrical installations in ships and offshore units. These standards provide general constructional requirements, test methods, and material specifications for power, control, and instrumentation cables.

IEC 60092-350 outlines the general construction and test methods for shipboard cables, focusing on conductors that are class 2 or class 5 stranded copper, suitable for fixed installations. It emphasises durability in marine environments, including resistance to vibration and salt exposure. Complementing this, IEC 60092-351 specifies requirements for insulating materials, detailing electrical, mechanical, and thermal characteristics of XLPE, ensuring it maintains integrity at voltages up to 1 kV. This standard ensures the insulation's dielectric strength and resistance to ageing, crucial for long-term performance on vessels.

For power cables with extruded solid insulation, IEC 60092-353 applies, covering non-radial field designs rated at 0.6/1 kV (up to 1.2 kV maximum). It addresses conductor screening and voltage ratings, preventing electrical faults in humid conditions. Meanwhile, IEC 60092-359 focuses on sheathing materials, testing for mechanical and flame properties in shipboard applications. This ensures the LSOH sheath withstands abrasion and environmental stresses.

Fire safety is rigorously tested under IEC 60332-1 and IEC 60332-3-22. The former evaluates vertical flame propagation on a single insulated wire, where the flame is applied for a specified time, and charring must not exceed limits. IEC 60332-3-22 assesses bunched cables in a vertical setup, simulating real shipboard clusters, with category A requiring no flame spread beyond 2.5 metres. These tests confirm the cables' flame retardant nature, preventing fire escalation in engine rooms or accommodation areas.

Halogen-free properties are verified via IEC 60754-1/2, measuring acidity and halogen content in combustion gases. Part 1 quantifies halogen release, while Part 2 assesses corrosivity through pH and conductivity, ensuring no harmful acids form that could damage electronics or harm personnel.

Low smoke emission is tested under IEC 61034, using a 3m cube chamber to measure light transmittance during burning. Transmittance must remain above 60%, allowing visibility for evacuation in smoke-filled corridors.

In South Africa, these standards align with SANS equivalents, supporting local certification by bodies like the South African Bureau of Standards (SABS). This compliance not only meets IMO SOLAS (Safety of Life at Sea) requirements but also enhances export potential for South African-built vessels, fostering industry growth in ports like Richards Bay.

Advantages in Marine Environments

The primary advantages stem from their flame retardant design, which limits fire spread and enhances safety on ships. In a fire, these cables self-extinguish, preventing propagation along cable runs, a common issue in engine compartments.

LSOH sheathing reduces smoke density, improving visibility and reducing inhalation risks during emergencies. Halogen-free composition avoids corrosive gases, protecting sensitive navigation equipment and extending vessel downtime.

XLPE insulation's hydrophobic nature resists water ingress, crucial in bilge areas or during flooding. Mechanically, they offer abrasion resistance, withstanding vibrations from engines or waves.

Environmentally, these cables support green shipping by minimising toxic emissions, aligning with South Africa's commitments under the Paris Agreement.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430