Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V HEPR Insulated, LSOH (SHF1) Sheathed, Armoured Flame Retardant Instrumentation & Control Cables (Multipair)

Application | These armoured cables are used on board of ships in all locations for fixed installations where cable protection is required. These cables are flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | DIN 89159/98 |

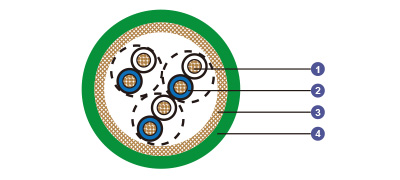

Construction | |

Conductors | Stranded copper conductor. |

Insulation | HEPR. |

Cabling Element | Pair. |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Pair: white/ blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Part No. | Construction No. of elements×No. of cores in element×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

M092-RE-3GCH-1P0.75 | 1×2×0.75 | 0.5 | 1.2 | 8.5 | 90 |

M092-RE-3GCH-2P0.75 | 2×2×0.75* | 0.5 | 1.3 | 9.5 | 130 |

M092-RE-3GCH-4P0.75 | 4×2×0.75 | 0.5 | 1.4 | 13.0 | 230 |

M092-RE-3GCH-7P0.75 | 7×2×0.75 | 0.5 | 1.8 | 15.5 | 340 |

M092-RE-3GCH-10P0.75 | 10×2×0.75 | 0.5 | 1.9 | 18.5 | 470 |

M092-RE-3GCH-14P0.75 | 14×2×0.75 | 0.5 | 2.0 | 21.0 | 610 |

M092-RE-3GCH-19P0.75 | 19×2×0.75 | 0.5 | 2.1 | 23.5 | 770 |

M092-RE-3GCH-24P0.75 | 24×2×0.75 | 0.5 | 2.2 | 26.5 | 950 |

In the intricate world of maritime engineering, where safety, reliability, and resilience are non-negotiable, the choice of cabling systems plays a pivotal role. Ships, whether colossal passenger liners or rugged commercial vessels, operate in some of the most demanding environments on Earth. From the corrosive bite of saltwater to the constant threat of fire in confined spaces, every component must be engineered to withstand extreme conditions while ensuring operational efficiency. Among these critical components are the 150/250V HEPR insulated, low smoke zero halogen (LSOH) sheathed, armoured, flame-retardant instrumentation and control cables (multipair). These cables, designed specifically for fixed installations on ships, are a marvel of modern engineering, blending advanced materials with rigorous standards to deliver unparalleled performance.

The Role of Instrumentation and Control Cables in Marine Environments

Instrumentation and control cables are the nervous system of a ship, transmitting signals and power to critical systems such as navigation, communication, propulsion control, and safety monitoring. Unlike standard cables used in terrestrial applications, marine cables must endure unique challenges: constant vibration, humidity, temperature fluctuations, and the ever-present risk of fire. These cables are often installed in confined spaces, such as engine rooms or control panels, where mechanical damage is a constant threat. This is where the armoured, flame-retardant, low smoke, and halogen-free properties of the 150/250V HEPR insulated cables shine.

These cables are designed for fixed installations across all areas of a ship, from the bridge to the engine room. Their robust construction ensures they can withstand physical stress, while their flame-retardant and low-smoke properties make them ideal for passenger ships, where human safety is paramount. The use of low smoke zero halogen (LSOH) materials ensures that, in the event of a fire, the cables produce minimal toxic fumes, reducing the risk of harm to crew and passengers and aiding safe evacuation.

Compliance with International Standards

The design and manufacture of these cables adhere to stringent international standards, ensuring they meet the rigorous demands of marine applications. Key standards include:

DIN 89159/98: A German standard specifying requirements for marine cables, focusing on their electrical and mechanical properties.

IEC 60092-351/375/359: These International Electrotechnical Commission (IEC) standards govern the design, construction, and testing of electrical installations in ships, including insulation materials and sheathing.

IEC 60332-1 and IEC 60332-3-22: These standards ensure the cables are flame-retardant, with IEC 60332-3-22 specifically addressing flame spread in bunched cables, critical for preventing fires from spreading in confined ship spaces.

IEC 60754-1/2: These standards confirm the cables are halogen-free, ensuring minimal emission of corrosive or toxic gases during combustion.

IEC 61034: This standard measures smoke density, ensuring the cables produce low smoke in fire conditions, improving visibility for evacuation and firefighting.

Compliance with these standards ensures that the cables are not only functional but also prioritise safety, a critical consideration in the high-stakes environment of maritime operations.

Applications in Maritime Settings

These cables are used across a wide range of applications on ships, including:

Navigation Systems: Transmitting data from radar, GPS, and other navigational instruments to the bridge.

Communication Systems: Supporting internal and external communication networks, including intercoms and satellite systems.

Propulsion and Engine Control: Relaying control signals to engines and propulsion systems for precise operation.

Safety and Monitoring Systems: Connecting sensors and alarms for fire detection, gas monitoring, and other safety-critical functions.

Their armoured construction makes them suitable for installation in high-risk areas, such as engine rooms or exposed decks, where mechanical damage is a concern. The flame-retardant and low-smoke properties are particularly valuable on passenger ships, where large numbers of people rely on clear evacuation routes and safe air quality in emergencies.

Why These Cables Matter for South Africa’s Maritime Industry

South Africa, with its extensive coastline and bustling ports like Durban and Cape Town, plays a significant role in global maritime trade. The country’s shipbuilding and repair industries, as well as its growing cruise tourism sector, rely on high-quality marine cables to ensure safety and operational efficiency. The use of 150/250V HEPR insulated, LSOH sheathed, armoured cables aligns with international safety standards, making South African vessels competitive and compliant in global markets.

Moreover, the emphasis on low smoke and halogen-free materials resonates with South Africa’s commitment to environmental and human safety. In the event of a fire, these cables reduce the risk of toxic exposure, protecting crew members and passengers—many of whom may be tourists contributing to the local economy. For South African shipbuilders, specifying these cables ensures compliance with international regulations, enhancing the reputation of locally built or serviced vessels.

The 150/250V HEPR insulated, LSOH sheathed, armoured, flame-retardant instrumentation and control cables are a testament to the ingenuity of modern engineering. Designed to meet the unique challenges of marine environments, these cables combine stranded copper conductors, HEPR insulation, copper wire braid armour, and LSOH sheathing to deliver reliability, safety, and performance. Their compliance with stringent international standards ensures they are fit for purpose on everything from passenger liners to commercial vessels.

For South Africa, a nation with a proud maritime heritage, these cables are more than just components—they are critical enablers of safe and efficient seafaring. As technology evolves and the maritime industry embraces sustainability and digitalisation, these cables will continue to play a vital role, adapting to meet the needs of tomorrow’s ships. Whether navigating stormy seas or ensuring the safety of thousands of passengers, these cables are the unsung heroes of the maritime world, quietly powering the systems that keep ships sailing.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430