Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V Mica Tape + HEPR Insulated, LSOH (SHF1) Sheathed, Armoured Fire Resistant Instrumentation & Control Cables (Multipair)

Application | These cables are used on board of ships in all locations for fixed installations complying with IEC standards 60092-352 in safety circuit, where fire resistance is required. These cables are fire resistant, flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | DIN 89159 |

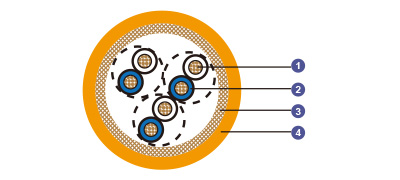

Construction | |

Conductors | Stranded copper conductor. |

Insulation | Mica tape + HEPR. |

Cabling Element | Pair. |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Part No. | Construction No. of elements×No. of cores in element×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

MFR-M3GCH-1P0.75 | 1×2×0.75 | 0.5 | 1.2 | 10.5 | 110 |

MFR-M3GCH-2P0.75 | 2×2×0.75* | 0.5 | 1.3 | 11.0 | 150 |

MFR-M3GCH-4P0.75 | 4×2×0.75 | 0.5 | 1.4 | 16.0 | 270 |

MFR-M3GCH-7P0.75 | 7×2×0.75 | 0.5 | 1.8 | 19.0 | 400 |

MFR-M3GCH-10P0.75 | 10×2×0.75 | 0.5 | 1.9 | 22.0 | 560 |

MFR-M3GCH-14P0.75 | 14×2×0.75 | 0.5 | 2.0 | 27.0 | 740 |

MFR-M3GCH-19P0.75 | 19×2×0.75 | 0.5 | 2.1 | 29.0 | 930 |

MFR-M3GCH-24P0.75 | 24×2×0.75 | 0.5 | 2.2 | 31.0 | 1110 |

Introduction

In the demanding world of maritime operations, where safety, reliability, and performance are non-negotiable, the choice of cabling systems plays a pivotal role. Among the most critical components are 150/250V Mica Tape + HEPR Insulated, Low Smoke Zero Halogen (LSOH) Sheathed, Armored Fire Resistant Instrumentation and Control Cables (Multipair). These cables are engineered to withstand extreme conditions, ensuring operational continuity in the harshest environments, such as those found on ships and offshore platforms.

Understanding Fire-Resistant Instrumentation Cables

What Are Instrumentation and Control Cables?

Instrumentation and control cables are specialised electrical cables designed to transmit low-voltage signals for monitoring and controlling equipment. In maritime settings, these cables connect sensors, control systems, and instrumentation devices, enabling critical functions such as navigation, communication, and engine monitoring. Unlike standard power cables, instrumentation cables are built to handle low-power signals with high precision, ensuring minimal signal interference and maximum reliability.

The 150/250V Mica Tape + HEPR Insulated, LSOH (SHF1) Sheathed, Armored Fire Resistant Instrumentation and Control Cables (Multipair) are a premium subset of these cables, specifically designed for environments where fire safety and operational continuity are paramount. Their multipair configuration allows them to carry multiple signal channels within a single cable, making them ideal for complex control systems on ships.

Key Features and Construction

The construction of these cables is a testament to advanced engineering, combining materials and designs that prioritise safety, durability, and performance. Below is a detailed breakdown of their components, as specified in the provided technical document:

Conductors: Stranded copper conductors are used for flexibility and efficient signal transmission. Stranded conductors are less prone to breakage under mechanical stress, making them suitable for the dynamic conditions of maritime environments.

Insulation: The cables feature a dual-layer insulation system comprising mica tape and High Electron Proton Rubber (HEPR). Mica tape provides exceptional fire resistance, maintaining circuit integrity even under direct flame exposure. HEPR, a high-performance elastomer, enhances insulation properties, offering resistance to heat, moisture, and chemical degradation.

Cabling Element: The cables are configured in pairs, with each pair consisting of two cores (white and blue) identified by printed pair and core numbers. This multipair design allows for the simultaneous transmission of multiple signals, reducing the need for multiple cables and simplifying installation.

Armour: A copper wire braid serves as the armour, providing mechanical protection against physical damage and electromagnetic interference (EMI). This is critical in maritime settings, where equipment is exposed to vibrations, impacts, and electromagnetic noise from nearby machinery.

Outer Sheath: The Low Smoke Zero Halogen (LSOH) SHF1 sheath is a standout feature. This material is flame-retardant, emits minimal smoke, and releases no toxic halogen gases when exposed to fire, ensuring safer evacuation and firefighting conditions.

Mechanical and Thermal Properties: The cables have a bending radius of 6 times the outer diameter (OD), allowing for flexible installation in confined spaces. They operate reliably within a temperature range of -30°C to +75°C, accommodating the extreme conditions of maritime environments.

Why Fire Resistance Matters in Maritime Environments

Maritime environments pose unique challenges for electrical systems. Ships, whether passenger vessels, cargo carriers, or offshore platforms, operate in confined spaces where fire hazards are a significant concern. A fire onboard can spread rapidly, and the presence of smoke and toxic gases can hinder evacuation and firefighting efforts. The fire-resistant properties of these cables address these risks in several ways:

Circuit Integrity: The mica tape insulation ensures that the cables continue to function during a fire, maintaining critical systems such as fire alarms, emergency lighting, and communication networks.

Low Smoke Emission: The LSOH sheath minimises smoke production, improving visibility for crew and passengers during evacuation.

Halogen-Free Design: By eliminating halogenated compounds, the cables prevent the release of toxic gases, reducing health risks in fire scenarios.

Flame Retardancy: Compliance with IEC 60332 standards ensures that the cables do not contribute to fire propagation, limiting the spread of flames.

Applications in Maritime Settings

The primary application of these cables is in fixed installations on ships, as outlined in IEC 60092-352. They are used in safety circuits, instrumentation systems, and control networks across various maritime vessels, including:

Passenger Ships: These cables ensure the reliability of navigation, communication, and emergency systems, protecting passengers and crew.

Commercial Vessels: Cargo ships and tankers rely on these cables for monitoring and controlling critical equipment, such as engines and cargo handling systems.

Offshore Platforms: In oil and gas platforms, the cables support instrumentation for monitoring pressure, temperature, and other parameters in hazardous environments.

Their fire-resistant and low-smoke properties make them particularly suitable for installations where safety is paramount, such as in engine rooms, control rooms, and passenger areas.

Advantages Over Traditional Cables

Compared to traditional instrumentation cables, the 150/250V Mica Tape + HEPR Insulated, LSOH Sheathed, Armored Fire Resistant Cables offer several advantages:

Enhanced Fire Safety: The combination of mica tape and LSOH materials provides superior fire resistance and safety compared to PVC-insulated cables, which may emit toxic gases.

Durability: The copper wire braid armour enhances mechanical strength, making the cables suitable for harsh maritime environments.

Signal Integrity: The multipair configuration and high-quality insulation minimise signal loss and interference, ensuring reliable data transmission.

Compliance: Adherence to IEC and DIN standards ensures global acceptance, critical for South African vessels operating in international waters.

The 150/250V Mica Tape + HEPR Insulated, LSOH (SHF1) Sheathed, Armored Fire Resistant Instrumentation and Control Cables (Multipair) represent the pinnacle of maritime cabling technology. Their fire-resistant, low-smoke, and halogen-free properties make them essential for ensuring safety and reliability on ships and offshore platforms. In South Africa, where the maritime sector is a cornerstone of economic activity, these cables are proving their worth in applications ranging from passenger ferries to offshore platforms. By adhering to international standards and leveraging advanced materials, these cables offer a robust solution for the challenges of modern maritime operations. As the industry continues to innovate, these cables will remain a critical component in safeguarding lives and assets at sea.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430