Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Armoured Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These cables are used on board of ships in all locations for fixed installations complying with IEC standards 60092-352 in safety circuit, where fire resistance is required. These cables are fire resistant, flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

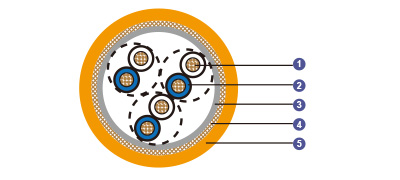

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | Mica tape + XLPE. |

Cabling Element | Pair/Triple. |

Inner Covering | Lapped polyester tape. |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

When you’re out at sea, whether on a massive cruise liner or a sturdy cargo vessel, safety is non-negotiable. Ships are floating ecosystems, packed with complex electrical systems that keep everything from navigation to communication running smoothly. But what happens when fire breaks out in such a confined, high-stakes environment? This is where 150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Armoured Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple) come into play. These cables aren’t just wires; they’re lifelines designed to keep critical systems operational even in the worst-case scenarios.

The Harsh Reality of Fires at Sea

Fires on ships are a nightmare. With limited escape routes and the ever-present risk of spreading flames, a fire can turn catastrophic in minutes. In 2022, a fire on a passenger ferry in the Baltic Sea highlighted the importance of fire-resistant systems, as critical navigation and communication circuits remained operational, allowing the crew to manage the crisis effectively. This is where fire-resistant instrumentation and control cables shine. Designed specifically for marine environments, these cables ensure that vital safety circuits—think fire alarms, emergency lighting, and communication systems—stay functional during a fire.

These cables are used in fixed installations on ships, complying with stringent international standards like IEC 60092-352. They’re engineered to be fire-resistant, flame-retardant, low smoke, and halogen-free, making them ideal for passenger ships and commercial vessels where safety is paramount. But what makes these cables so special? Let’s unpack their construction and why each component matters.

Anatomy of a Fire-Resistant Cable

To understand why these cables are so effective, we need to break down their construction. Each layer serves a specific purpose, combining to create a robust, reliable solution for maritime environments.

Conductors: The Core of Connectivity

At the heart of these cables are Class 2 stranded copper conductors. Unlike solid conductors, stranded copper is flexible, making it easier to install in the tight, winding spaces of a ship’s infrastructure. The copper ensures excellent electrical conductivity, critical for maintaining signal integrity in instrumentation and control systems. Whether it’s a pair (two cores) or a triple (three cores), these conductors form the foundation for reliable data and power transmission.

Insulation: The Fire-Resistant Shield

The insulation is where the magic happens. These cables use a combination of mica tape and cross-linked polyethylene (XLPE). Mica tape is a mineral-based material with exceptional thermal resistance, capable of withstanding temperatures up to 950°C. This is crucial for fire resistance, as it ensures the cable can maintain circuit integrity even when exposed to intense heat. XLPE, on the other hand, provides excellent electrical insulation and mechanical strength, protecting the conductors from environmental stresses like moisture and vibration, which are common at sea.

Cabling Element: Pairs and Triples

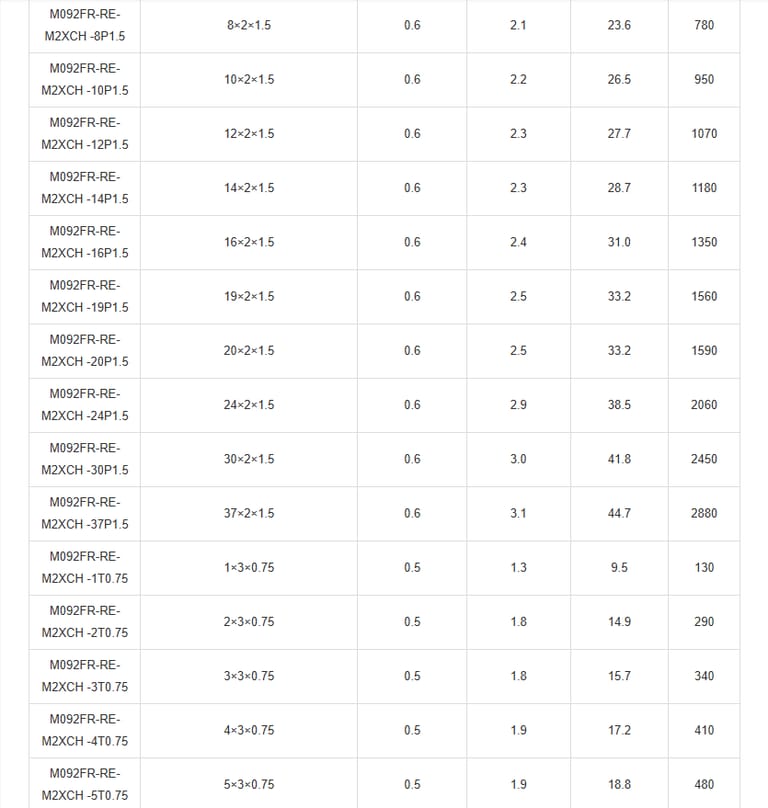

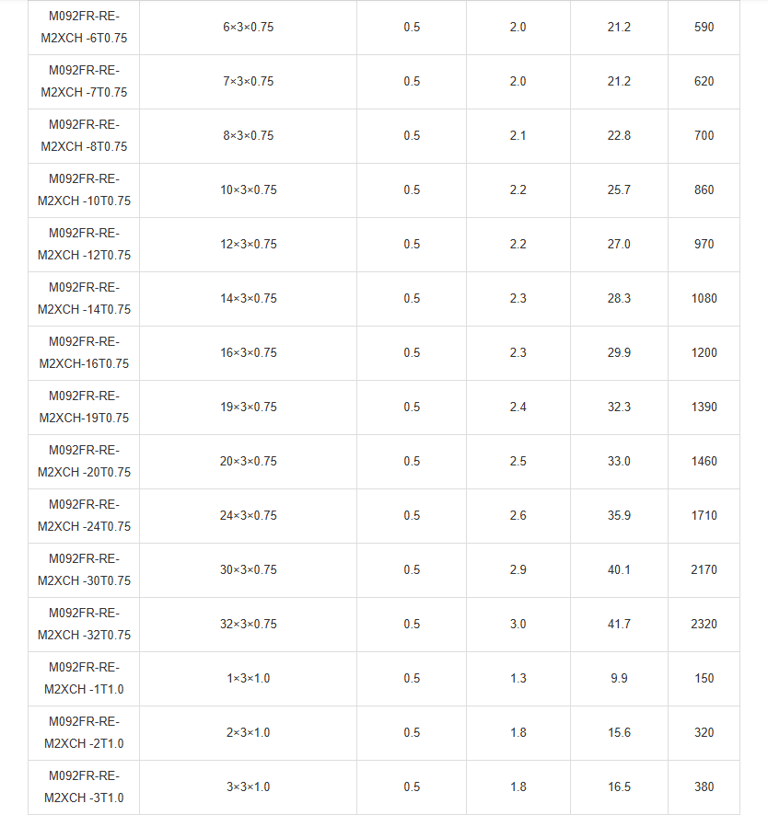

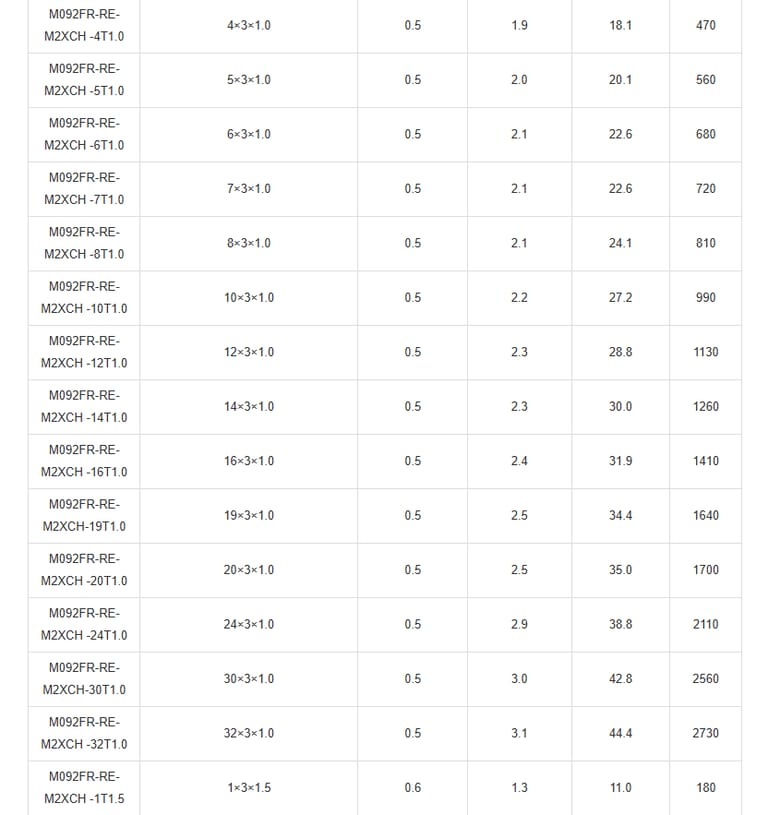

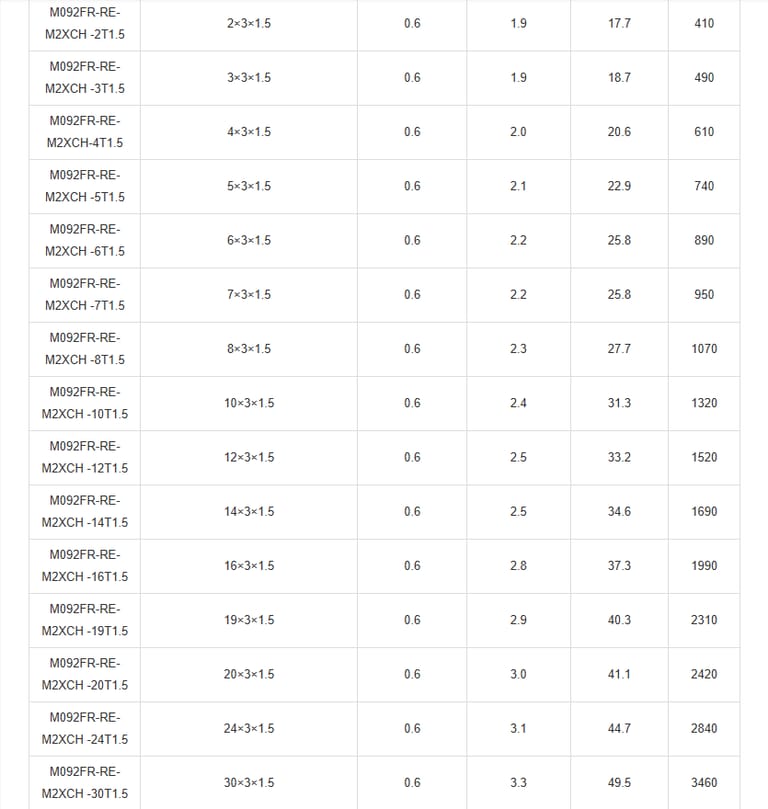

The cables are available in multipair or multitriple configurations, meaning they can contain multiple pairs (two conductors) or triples (three conductors) within a single cable. This is ideal for complex instrumentation systems, where multiple signals need to be transmitted simultaneously. For example, a cable with 24 pairs of 0.75 mm² conductors can handle a multitude of control signals, from temperature sensors to engine monitoring systems. Each pair or triple is clearly identified—pairs with white and blue cores, triples with white, blue, and red—complete with printed numbers for easy installation and maintenance.

Inner Covering and Armour: Durability Meets Protection

A lapped polyester tape serves as the inner covering, providing an additional layer of insulation and protection. Over this, a copper wire braid acts as the armour, shielding the cable from electromagnetic interference (EMI) and physical damage. EMI is a real concern on ships, where radar systems, radios, and other electronics can create signal noise. The copper braid ensures that sensitive instrumentation signals remain clear and reliable.

Outer Sheath: Low Smoke, Halogen-Free Safety

The LSOH (Low Smoke Zero Halogen) SHF1 sheath is the final layer. In a fire, traditional PVC cables release toxic halogen gases and dense smoke, which can be deadly in enclosed spaces like a ship’s corridors. LSOH materials, however, produce minimal smoke and no halogen gases, improving visibility and reducing health risks for crew and passengers during evacuation. The SHF1 designation indicates the sheath meets specific marine standards for flexibility and durability in harsh conditions.

Standards That Save Lives

These cables don’t just meet one standard—they comply with a suite of IEC standards designed to ensure safety and performance in marine environments:

IEC 60092-350/351/376/359: These govern the design, construction, and installation of electrical cables on ships, ensuring they’re fit for purpose in harsh maritime conditions.

IEC 60331-21: Tests fire resistance, ensuring the cables can maintain circuit integrity under fire conditions for a specified period.

IEC 60332-1 and 60332-3-22: These standards confirm the cables are flame-retardant, preventing the spread of fire along cable runs.

IEC 60754-1/2: Verifies that the cables are halogen-free, producing no toxic gases when exposed to fire.

IEC 61034: Ensures low smoke emission, critical for maintaining visibility in a fire.

By adhering to these standards, the cables guarantee reliability in the most extreme conditions, giving ship designers and operators peace of mind.

Why These Cables Matter for Maritime Safety

Imagine a fire breaking out in the engine room of a passenger ship carrying thousands of people. The crew needs to activate fire suppression systems, communicate with rescue teams, and guide passengers to safety. Without fire-resistant cables, these critical systems could fail, leading to chaos. These 150/250V Mica Tape + XLPE Insulated, LSOH Sheathed, Armoured Cables ensure that safety circuits remain operational, even when flames are raging.

Their fire-resistant properties, thanks to the mica tape and XLPE insulation, allow them to maintain circuit integrity for extended periods during a fire. The flame-retardant design prevents the cables from contributing to the fire’s spread, while the low smoke, halogen-free sheath reduces risks to human health. This combination is particularly crucial on passenger ships, where large numbers of people rely on clear evacuation routes and functioning safety systems.

Fire-resistant cables are more than just a technical specification—they’re a critical component of maritime safety. By combining mica tape and XLPE insulation, copper wire braid armour, and LSOH sheathing, these cables provide unmatched reliability in the harshest conditions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430