Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Overall Screened & Armoured Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These cables are used on board of ships in all locations for fixed installations complying with IEC standards 60092-352 in safety circuit, where fire resistance is required. These cables are fire resistant, flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

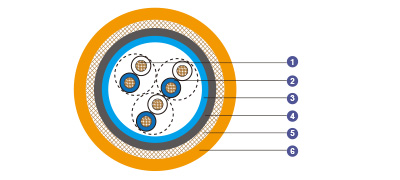

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | Mica tape + XLPE insulation. |

Cabling Element | Pair/Triple. |

Overall Screen | Al/polyester tape. |

Drain Wire | Tinned copper wire. |

Inner Covering | Lapped polyester tape. |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

In the vast expanse of the ocean, where ships brave tempests and traverse uncharted waters, safety is paramount. Imagine a colossal passenger liner cutting through the waves, its decks alive with holidaymakers, crew, and intricate machinery. Beneath the surface, a network of cables pulses like the nervous system of a living organism, transmitting vital signals for navigation, communication, and emergency systems. But what happens when fire strikes – a peril as old as seafaring itself? Enter the 150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Overall Screened & Armoured Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple). These aren't just wires; they're engineered lifelines designed to withstand infernos, ensuring that critical systems remain operational when it matters most.

The Crucial Role in Maritime Safety

These cables are tailored for onboard ship installations, particularly in safety circuits where fire resistance is non-negotiable. Compliant with IEC 60092-352, they find their place in fixed installations across all ship locations, from engine rooms to bridge controls. What sets them apart is their fire-resistant, flame-retardant, low-smoke, and halogen-free properties. This makes them ideal for passenger ships and commercial vessels alike, where dense populations amplify the risks of fire.

Picture a fire breaking out in a ship's galley. Smoke billows, flames lick at bulkheads, and panic ensues. Ordinary cables might melt, short-circuit, or release toxic fumes, crippling alarms, sprinklers, or evacuation signals. In contrast, these fire-resistant cables maintain integrity, allowing instrumentation and control systems – think sensors monitoring engine temperatures or valves controlling fire suppression – to function amid the chaos. The "multipair/multitriple" designation refers to their configuration: bundles of paired or tripled conductors, perfect for transmitting multiple signals simultaneously without interference.

In South African waters, where our ports like Durban and Cape Town handle everything from cargo freighters to luxury liners, such cables align with stringent maritime regulations. The International Maritime Organization (IMO) emphasises fire safety, and these cables help vessels meet SOLAS (Safety of Life at Sea) conventions. Their low-smoke zero-halogen (LSOH) sheath minimises visibility-obscuring smoke and corrosive gases, which could otherwise turn escape routes into death traps. Halogens, like chlorine in PVC cables, produce hydrochloric acid when burning, eroding equipment and harming lungs. By opting for LSOH, these cables prioritise human health and equipment longevity.

In-Depth Analysis: Performance Under Pressure

To truly appreciate these cables, consider their fire-resistant mechanism. During a blaze, mica tape forms a ceramic-like barrier, insulating conductors as organic materials char. XLPE cross-linking prevents dripping or melting, maintaining structure. Tests show circuit integrity for over 90 minutes at 750°C – enough time for evacuation or firefighting.

Compared to non-armoured variants, the copper braid adds mechanical robustness, reducing failure from debris. Overall screening minimises crosstalk in multipairs, ensuring accurate data from PLCs (programmable logic controllers) to actuators.

Environmentally, LSOH sheaths align with green shipping trends. The IMO's 2020 sulphur cap pushes low-emission tech; halogen-free cables reduce ecological footprint during manufacture and disposal.

Challenges include cost: premium materials like mica inflate prices, but savings accrue from reliability and compliance. Installation demands skilled labour – improper bending could compromise armour.

Future innovations might integrate fibre optics for higher bandwidth or smart sensors for real-time health monitoring. In South Africa, with our growing shipbuilding sector in places like Saldanha Bay, adopting such cables bolsters export competitiveness.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430