Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Overall Screened Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These cables are used on board of ships in all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352 in safety circuit, where fire resistance is required. These cables are fire resistant, flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

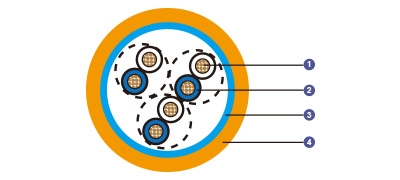

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | Mica tape + XLPE. |

Cabling Element | Pair/Triple. |

Overall Screen | Al/polyester tape. |

Drain Wire | Tinned copper wire. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD (OD>25mm); 4×OD (OD ≤25mm) |

In the vast expanse of the world's oceans, where ships navigate treacherous waters and face unpredictable hazards, the unsung heroes of maritime engineering often lie hidden within the vessel's structure. These are the specialised cables that ensure critical systems remain operational, even in the face of fire. But what exactly makes 150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Overall Screened Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple) so vital?

Understanding the Basics: What Are These Cables?

At their core, instrumentation and control cables are the nervous system of a ship. They transmit low-voltage signals (typically 150/250V) between sensors, controllers, and actuators, enabling everything from engine monitoring to navigation systems. Unlike standard power cables, which handle higher currents for propulsion or lighting, these are optimised for data accuracy and minimal interference. The "multipair" or "multitriple" designation refers to their configuration: bundles of twisted pairs or triples of conductors, which reduce electromagnetic crosstalk and ensure precise signal transmission.

The fire-resistant variant we're examining incorporates several key features to combat the perils of shipboard fires, which can spread rapidly due to confined spaces and flammable materials. According to the International Maritime Organization (IMO), fires account for a significant portion of maritime incidents, often exacerbated by cable failures that disrupt safety circuits. These cables comply with IEC 60092-352 for electrical installations in ships, ensuring they remain functional during emergencies.

Let's break down the nomenclature: "Mica Tape + XLPE Insulated" indicates the dual-layer insulation system. Mica tape provides exceptional fire resistance, while Cross-Linked Polyethylene (XLPE) offers durable electrical insulation. "LSOH (SHF1) Sheathed" means Low Smoke Zero Halogen sheathing of type SHF1, which minimises toxic emissions. "Overall Screened" refers to an aluminium/polyester tape shield with a tinned copper drain wire, protecting against electromagnetic interference (EMI). "Fire Resistant" ensures circuit integrity under fire conditions, as per IEC 60331-21.

In South African contexts, where vessels must adhere to both international standards and local regulations under the South African Maritime Safety Authority (SAMSA), these cables are particularly relevant. They are used in safety circuits on passenger ships and commercial vessels, where mechanical risks are low but fire hazards are ever-present.

Applications in Maritime Environments:

These cables shine in shipboard applications where reliability is non-negotiable. In engine control rooms, they link sensors monitoring temperature, pressure, and vibrations to PLCs (Programmable Logic Controllers). During a fire, mica insulation keeps circuits alive, allowing automated shutdowns or sprinkler activations.

On offshore platforms off South Africa's coast, like those in the Agulhas Current, they withstand salt spray and hydrocarbons. Their halogen-free nature aligns with environmental regulations, reducing pollution risks.

In passenger ferries operating between Cape Town and Robben Island, low smoke properties protect tourists and crew. Globally, post-incidents like the 2012 Costa Concordia disaster highlight the need for such tech—where cable failures contributed to navigation losses.

Advancements in materials science are pushing boundaries. Future iterations may incorporate nanomaterials for lighter weights or smart sensors for predictive maintenance, integrating with IoT for real-time health monitoring.

Conclusion:

So, why are fire-resistant instrumentation cables crucial for maritime safety? They represent the pinnacle of engineering resilience, ensuring that when flames rage, critical systems endure. From the mica tape's unyielding barrier to the LSOH sheath's life-saving low emissions, every element is meticulously designed. In South Africa, where the ocean economy contributes billions to GDP, adopting these cables isn't just prudent—it's essential for protecting lives, assets, and the environment.

As ships evolve towards autonomy and electrification, these cables will remain foundational. By understanding their intricacies, we appreciate the silent guardians that keep our maritime world afloat.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430