Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Instrumentation & Control Cables (Multicore)

Application | These cables are used on board of ships at all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352. These cables are flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

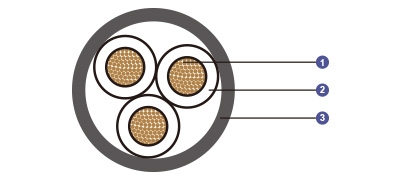

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | XLPE. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | White with printed number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 4×OD |

Dimensions and Weight

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

M092-RE-2XH-2C0.75 | 2×0.75 | 0.5 | 1.1 | 6.2 | 50 |

M092-RE-2XH-3C0.75 | 3×0.75 | 0.5 | 1.1 | 6.5 | 60 |

M092-RE-2XH-5C0.75 | 5×0.75 | 0.5 | 1.2 | 7.7 | 80 |

M092-RE-2XH-7C0.75 | 7×0.75 | 0.5 | 1.2 | 8.3 | 100 |

M092-RE-2XH-12C0.75 | 12×0.75 | 0.5 | 1.3 | 10.9 | 170 |

M092-RE-2XH-19C0.75 | 19×0.75 | 0.5 | 1.6 | 13.0 | 250 |

M092-RE-2XH-27C0.75 | 27×0.75 | 0.5 | 1.7 | 15.6 | 350 |

M092-RE-2XH-37C0.75 | 37×0.75 | 0.5 | 1.9 | 17.6 | 470 |

M092-RE-2XH-2C1.0 | 2×1.0 | 0.5 | 1.1 | 6.6 | 60 |

M092-RE-2XH-3C1.0 | 3×1.0 | 0.5 | 1.2 | 7.0 | 70 |

M092-RE-2XH-5C1.0 | 5×1.0 | 0.5 | 1.2 | 8.2 | 100 |

M092-RE-2XH-7C1.0 | 7×1.0 | 0.5 | 1.3 | 9.1 | 130 |

M092-RE-2XH-12C1.0 | 12×1.0 | 0.5 | 1.4 | 11.7 | 210 |

M092-RE-2XH-19C1.0 | 19×1.0 | 0.5 | 1.7 | 14.0 | 310 |

M092-RE-2XH-27C1.0 | 27×1.0 | 0.5 | 1.9 | 16.8 | 430 |

M092-RE-2XH-37C1.0 | 37×1.0 | 0.5 | 2.0 | 19.0 | 580 |

In the intricate and demanding world of maritime engineering, the choice of cabling can mean the difference between safety and catastrophe. Among the unsung heroes of modern shipbuilding are 150/250V XLPE insulated, LSOH (SHF1) sheathed flame-retardant instrumentation and control cables (multicore). These cables, designed to meet stringent international standards, are vital for ensuring reliable and safe electrical systems on board ships.

The Role of Instrumentation and Control Cables in Maritime Operations

Instrumentation and control cables are the nervous system of a ship, transmitting signals and power to critical systems such as navigation, communication, and engine control. These cables must operate flawlessly under harsh marine conditions, including exposure to moisture, temperature extremes, and potential fire hazards. The 150/250V XLPE insulated, LSOH (SHF1) sheathed cables are specifically engineered for fixed installations in areas not subject to mechanical stress, making them ideal for a wide range of maritime applications.

These cables comply with the International Electrotechnical Commission (IEC) standards, notably IEC 60092-352, which governs electrical installations in ships. Their flame-retardant, low smoke, and halogen-free properties make them particularly suited for passenger ships, where safety is paramount, as well as other commercial vessels navigating the world’s oceans.

Understanding the Construction of XLPE Insulated, LSOH Sheathed Cables

To appreciate the engineering behind these cables, let’s break down their construction:

Conductors

The cables use Class 2 stranded copper conductors, which strike a balance between flexibility and durability. Stranded conductors consist of multiple fine copper wires twisted together, offering improved flexibility compared to solid conductors while maintaining excellent electrical conductivity. This makes them suitable for fixed installations where some degree of bending is required during installation.

Insulation

The insulation material is cross-linked polyethylene (XLPE), a thermoset polymer known for its superior electrical and thermal properties. XLPE insulation provides excellent resistance to high temperatures (up to 80°C) and electrical stress, ensuring reliable performance in the demanding marine environment. With a nominal insulation thickness of 0.5 mm, these cables maintain a compact profile while delivering robust dielectric strength.

Outer Sheath

The outer sheath is made of low smoke zero halogen (LSOH) material, specifically SHF1, with the option for SHF2 upon request. The LSOH sheath is a critical feature, as it minimises the emission of toxic gases and smoke in the event of a fire. This is particularly important on ships, where confined spaces and limited escape routes heighten the risks associated with fire. The sheath’s thickness varies from 1.1 mm to 2.0 mm, depending on the number of cores and cross-sectional area, ensuring adequate protection without compromising flexibility.

Core Identification

The cables feature white cores with printed numbers for easy identification during installation and maintenance. This clear labelling reduces the risk of errors in complex wiring systems, enhancing operational efficiency and safety.

Compliance with International Standards

These cables adhere to a suite of IEC standards, ensuring their suitability for maritime applications:

IEC 60092-350/351/376/359: These standards cover the general construction, testing, and performance requirements for electrical cables used in ships. They ensure the cables meet rigorous safety and operational criteria.

IEC 60332-1 and IEC 60332-3-22: These standards test the cables’ flame-retardant properties, ensuring they resist fire propagation. IEC 60332-3-22 specifically evaluates cables in bundled configurations, simulating real-world installations.

IEC 60754-1/2: These standards confirm the cables’ halogen-free properties, ensuring minimal emission of corrosive gases during combustion.

IEC 61034: This standard measures smoke density, verifying the low-smoke characteristics of the LSOH sheath, which is critical for maintaining visibility in fire scenarios.

This compliance ensures that the cables meet the highest safety and performance benchmarks, making them a trusted choice for maritime engineers worldwide.

Why LSOH and Flame-Retardant Properties Matter

The low smoke zero halogen (LSOH) sheath is a standout feature of these cables. In a fire, traditional cables with halogenated materials (such as PVC) can release toxic gases like hydrogen chloride, which pose severe health risks and corrode equipment. LSOH cables, by contrast, emit minimal smoke and no halogenated gases, improving visibility and reducing health hazards for passengers and crew. This is especially critical on passenger ships, where large numbers of people may need to evacuate quickly.

The flame-retardant properties, validated by IEC 60332 standards, ensure that the cables resist fire propagation. In a marine environment, where fires can spread rapidly and escape routes are limited, this feature significantly enhances safety.

Applications in Maritime Environments

These cables are used across a variety of maritime applications, including:

Navigation Systems: Ensuring accurate and reliable signal transmission for radar, GPS, and other navigational aids.

Communication Systems: Supporting internal and external communication networks, critical for coordination and safety.

Engine Control: Transmitting control signals to propulsion and auxiliary systems, ensuring smooth operation.

Monitoring Systems: Facilitating real-time data collection for environmental and operational monitoring.

Their versatility makes them suitable for both passenger ships and commercial vessels, from cruise liners to cargo ships. The cables’ compliance with IEC 60092-352 ensures they can be installed in all shipboard locations not exposed to mechanical damage, such as control rooms, engine rooms, and bridge areas.

The Broader Impact on Maritime Safety and Efficiency

The adoption of 150/250V XLPE insulated, LSOH sheathed cables reflects the maritime industry’s commitment to safety and environmental responsibility. By reducing the risks associated with fire and toxic emissions, these cables protect lives and assets. Their durability and reliability also minimise maintenance costs and downtime, contributing to operational efficiency.

Moreover, the use of halogen-free materials aligns with global trends towards sustainability. As regulations tighten around emissions and environmental impact, LSOH cables position shipbuilders and operators to meet future standards while maintaining high performance.

Conclusion

The 150/250V XLPE insulated, LSOH (SHF1) sheathed flame-retardant instrumentation and control cables are a cornerstone of modern maritime electrical systems. Their robust construction, compliance with stringent IEC standards, and safety-focused features make them indispensable for ensuring reliable and safe operations at sea. From their Class 2 stranded copper conductors to their low smoke, halogen-free sheaths, these cables embody the intersection of engineering excellence and safety innovation.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430