Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V XLPE Insulated, LSOH (SHF1) Sheathed Flame Retardant Instrumentation & Control Cables (Multicore)

Application | These cables are used on board of ships in all locations for fixed installations where cable protection is required. These cables are flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | DIN 89159/98 |

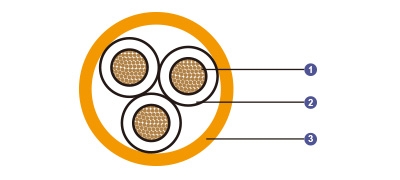

Construction | |

Conductors | Stranded copper conductor. |

Insulation | HEPR. |

Cabling Element | Pair. |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Pair: white/ blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Dimensions and Weight

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

MFR-M2XH-2C0.75 | 2×0.75 | 0.5 | 1.1 | 6.3 | 63 |

MFR-M2XH-4C0.75 | 4×0.75 | 0.5 | 1.2 | 6.7 | 84 |

In the vast expanse of the world’s oceans, ships serve as floating ecosystems, carrying passengers, crew, and cargo across continents. These vessels, from luxurious cruise liners to robust commercial freighters, rely on intricate electrical systems to power navigation, communication, and critical operations. At the heart of these systems lie specialised cables designed to withstand the harsh marine environment while ensuring safety and reliability. Among these, 150/250V XLPE insulated, low smoke zero halogen (LSOH) sheathed, flame-retardant instrumentation and control cables (multicore) stand out as a cornerstone of maritime electrical engineering. But what makes these cables so essential for safe maritime operations?

The Maritime Environment: A Unique Challenge

The marine environment is one of the most demanding settings for electrical systems. Ships operate in conditions marked by high humidity, saltwater exposure, extreme temperatures, and constant vibration. Electrical cables on board must endure these challenges while maintaining performance and, most importantly, ensuring safety. A single fault in a cable could lead to catastrophic consequences, such as power failures, equipment malfunctions, or even fires. This is where XLPE insulated, LSOH sheathed cables come into play, offering a robust solution tailored to the maritime industry’s unique needs.

These cables, designed for fixed installations on ships, are used in critical applications such as instrumentation and control systems. They power sensors, communication devices, and control panels that monitor everything from engine performance to navigation systems. Their ability to resist fire, emit minimal smoke, and avoid releasing toxic halogen gases makes them indispensable, particularly on passenger ships where human safety is paramount.

Understanding the Construction of XLPE Insulated LSOH Cables

To appreciate why these cables are vital, it’s essential to understand their construction. Each component is meticulously engineered to meet stringent international standards and perform reliably under maritime conditions.

Conductors

The core of these cables consists of stranded copper conductors. Unlike solid conductors, stranded copper is made up of multiple thin wires twisted together, providing flexibility and durability. This construction allows the cables to withstand the constant vibrations and mechanical stresses experienced on a ship without breaking or losing conductivity. Copper is chosen for its excellent electrical conductivity, ensuring minimal energy loss during transmission.

Insulation

The conductors are insulated with cross-linked polyethylene (XLPE), specifically high electron-beam cross-linked polyethylene (HEPR). XLPE is a thermoset material, meaning it does not melt when exposed to high temperatures, unlike thermoplastic materials. This property enhances the cable’s ability to operate in temperatures ranging from -30°C to +75°C, a critical feature for ships navigating icy polar waters or tropical seas. XLPE also provides excellent electrical insulation, preventing short circuits and ensuring reliable signal transmission in instrumentation and control applications.

Cabling Element

These cables are typically multicore, with conductors arranged in pairs. Each pair is identified by a white and blue colour scheme, with printed pair and core numbers for easy identification during installation and maintenance. This organisation is crucial in complex shipboard systems, where hundreds of cables may run through confined spaces, and clarity is needed to avoid errors.

Armour

To protect the delicate conductors and insulation from mechanical damage, the cables are equipped with a copper wire braid armour. This layer shields the cable from external impacts, such as those caused by heavy equipment or accidental strikes during maintenance. The copper braid also provides electromagnetic shielding, reducing interference in sensitive instrumentation systems, which is vital for accurate data transmission in navigation and control applications.

Outer Sheath

The outer sheath is made of low smoke zero halogen (LSOH) material, specifically SHF1 grade, which is designed for maritime use. LSOH materials are engineered to emit minimal smoke and no halogen gases when exposed to fire. This is a critical feature in the confined spaces of a ship, where smoke inhalation and toxic fumes can pose significant risks to passengers and crew. The SHF1 designation indicates that the sheath meets specific mechanical and thermal requirements, ensuring durability in harsh marine conditions.

Applications in Maritime Operations

XLPE insulated LSOH cables are used in a wide range of fixed installations on ships. Their primary role is in instrumentation and control systems, which are the nervous system of a vessel. These systems include:

Navigation Systems: Cables connect sensors and radar equipment, ensuring accurate positioning and course plotting.

Communication Systems: They enable reliable voice and data communication, both within the ship and with external networks.

Engine Monitoring: Instrumentation cables transmit data from sensors monitoring engine performance, fuel consumption, and other critical parameters.

Safety Systems: They power fire detection, alarm systems, and emergency controls, ensuring rapid response in critical situations.

On passenger ships, such as cruise liners, these cables are particularly critical. The high density of people on board demands stringent safety measures, and the flame-retardant, low-smoke, and halogen-free properties of these cables reduce the risk of fire-related casualties. For commercial vessels like cargo ships or tankers, the cables’ durability ensures uninterrupted operations, even in harsh conditions.

Why LSOH Matters: Safety First

One of the standout features of these cables is their LSOH sheath. In a fire, traditional cables with PVC sheaths can release dense smoke and toxic halogen gases, such as hydrogen chloride. These emissions can obscure visibility, hinder evacuation, and cause severe health risks. In contrast, LSOH cables produce minimal smoke and no halogen gases, significantly improving safety in enclosed shipboard environments.

This is particularly critical on passenger ships, where thousands of people may be on board. A fire in such a setting could lead to panic, and poor visibility or toxic fumes could exacerbate the situation. By using LSOH cables, ship designers mitigate these risks, ensuring safer evacuation routes and reducing the likelihood of inhalation injuries.

XLPE insulated, LSOH sheathed, flame-retardant instrumentation and control cables are more than just components in a ship’s electrical system—they are lifelines that ensure safety, reliability, and efficiency at sea. Their robust construction, adherence to international standards, and specialised features like low smoke emission and halogen-free properties make them indispensable for maritime operations. From powering navigation systems to enabling rapid response in emergencies, these cables play a critical role in keeping ships and their occupants safe.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430