Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V XLPE Insulated, LSOH (SHF1) Sheathed, Overall Screened & Armoured Flame Retardant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These armoured cables are used on board of ships in all locations for fixed installations where cable protection is required. These cables are flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

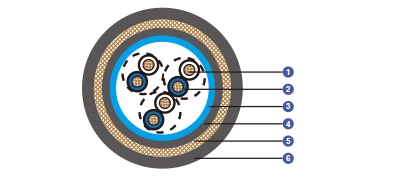

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | XLPE. |

Cabling Element | Pair/Triple. |

Overall Screen | Al/polyester tape. |

Inner Sheath | LSOH (SHF1). |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

In the vast expanse of the world's oceans, where colossal ships navigate treacherous waters, a hidden network of technology ensures everything runs smoothly. Imagine a passenger liner slicing through stormy seas off the coast of Durban, its engines humming, navigation systems plotting courses, and safety protocols monitoring every vital sign. Beneath the decks, in the bowels of these floating cities, lies a critical yet often overlooked hero: the 150/250V XLPE insulated, LSOH (SHF1) sheathed, overall screened and armoured flame retardant instrumentation and control cable. These multipair or multitriple cables are the unsung guardians of maritime safety and efficiency, designed to withstand the harshest environments while protecting lives and assets.

These cables aren't just wires; they're sophisticated assemblies engineered for the unique demands of shipboard installations. With cross-linked polyethylene (XLPE) insulation providing robust electrical performance, low smoke zero halogen (LSOH) sheathing ensuring minimal toxic emissions during fires, and copper wire braid armour offering mechanical protection, they represent the pinnacle of cable technology for marine applications. In an era where global trade relies on over 90,000 merchant ships transporting goods worth trillions of rands annually, understanding these cables reveals the intricate science that keeps our oceans connected and safe.

Applications: Where Reliability Meets the High Seas

On board ships, reliability isn't a luxury—it's a necessity. These armoured cables find their home in all locations for fixed installations where protection is paramount. Whether in engine rooms, control centres, or passenger areas, they transmit signals for instrumentation and control systems, ensuring precise monitoring of temperatures, pressures, and automation processes. Their flame retardant nature, combined with low smoke and halogen-free properties, makes them ideal for passenger ships and commercial vessels alike.

Consider a fire scenario: In confined ship spaces, traditional cables might release toxic halogens, exacerbating smoke and endangering lives. LSOH sheathing, specifically the SHF1 variant, minimises this risk by producing negligible smoke and no corrosive gases, allowing safer evacuation and firefighting. This is crucial on passenger vessels, where thousands of lives could be at stake. Upon request, SHF2 sheathing can be provided for even harsher conditions, offering enhanced mud resistance in offshore environments.

In marine settings, electromagnetic interference (EMI) from powerful engines or radar systems can disrupt signals. The overall screening—typically aluminium/polyester tape—shields against this, preserving data integrity for critical controls like alarm systems or propulsion monitoring. Armouring adds another layer, protecting against mechanical damage from vibrations, impacts, or rodent intrusion, common in ship holds.

These cables align with South Africa's growing offshore oil and gas sector, where platforms off Mossel Bay demand durable wiring. Globally, the maritime cable market is projected to grow as electrification of ships advances, reducing emissions in line with IMO regulations. By preventing signal loss and ensuring flame retardancy, these cables not only comply with safety mandates but also enhance operational efficiency, potentially saving millions in downtime costs.

Their versatility extends to fixed installations across the vessel, from bridge instrumentation to cargo hold sensors. In essence, they form the nervous system of a ship, relaying information that prevents disasters. As climate change intensifies storms, the resilience of such cables becomes even more vital, embodying the fusion of materials science and practical engineering for safer seas.

Standards: The Global Benchmarks for Safety and Performance

No engineering marvel operates in isolation; these cables adhere to stringent international standards, primarily from the International Electrotechnical Commission (IEC). The core standards—IEC 60092-350, 351, 376, and 359—govern electrical installations in ships, specifying construction, materials, and testing for offshore and marine cables. These ensure compatibility and reliability in high-voltage environments up to 250V.

Flame retardancy is tested under IEC 60332-1 for single cables and IEC 60332-3-22 for bunched installations, simulating fire propagation to confirm the cables won't spread flames. This is vital in ships, where fires can escalate rapidly. Halogen content is scrutinised via IEC 60754-1/2, ensuring low acidity in emissions to protect equipment and personnel from corrosion. Smoke density, critical for visibility during emergencies, falls under IEC 61034, mandating low smoke output.

These standards evolved from historical maritime disasters, like the 1912 Titanic sinking, which highlighted electrical failures, to modern incidents such as the 2019 Conception dive boat fire. By complying, manufacturers guarantee cables maintain circuit integrity, allowing systems to function amid flames.

In South African contexts, these align with SANS standards, facilitating exports to Europe and Asia. Compliance isn't mere bureaucracy; it's a scientific assurance that materials withstand thermal, electrical, and environmental stresses, fostering trust in global supply chains.

These cables epitomise how science safeguards our maritime world. From XLPE's resilience to LSOH's safety focus, they mitigate risks in an unpredictable ocean. As electric propulsion and autonomous ships emerge, such innovations will evolve, perhaps incorporating smart sensors for real-time monitoring. For South Africa, embracing these technologies strengthens our blue economy, ensuring safer, greener voyages ahead.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430