Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

150/250V XLPE Insulated, LSOH (SHF1) Sheathed, Overall Screened Flame Retardant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These cables are used on board of ships at all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352. These cables are flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

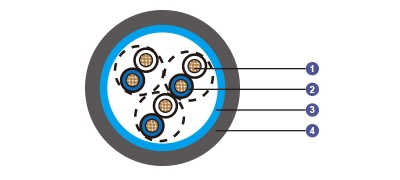

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | XLPE. |

Cabling Element | Pair/Triple. |

Overall Screen | Al/polyester tape. |

Drain Wire | Tinned copper wire. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

In the vast and unpredictable expanse of the world’s oceans, modern ships rely on sophisticated systems to ensure safety, efficiency, and reliability. At the heart of these systems lies a critical yet often overlooked component: instrumentation and control cables. Specifically, 150/250V XLPE insulated, low smoke zero halogen (LSOH) sheathed, overall screened, flame-retardant instrumentation and control cables (multipair/multitriple) are engineered to meet the rigorous demands of marine environments. These cables, compliant with international standards such as IEC 60092-352, are indispensable for fixed installations on ships, from colossal passenger liners to robust commercial vessels. But what makes these cables so vital, and how do their design and construction ensure they perform under the harshest conditions?

Applications: Powering Safe and Efficient Maritime Operations

Marine environments are among the most challenging for electrical systems. Ships operate in conditions of high humidity, temperature fluctuations, and constant vibration, all while requiring absolute reliability for navigation, communication, and control systems. The 150/250V XLPE insulated, LSOH sheathed, overall screened instrumentation and control cables are designed for fixed installations in locations not exposed to mechanical risk, ensuring seamless operation of critical systems.

These cables are used extensively across various shipboard applications, including control circuits, monitoring systems, and instrumentation for navigation, propulsion, and communication equipment. Their flame-retardant and low smoke zero halogen (LSOH) properties make them particularly suited for passenger ships, where safety is paramount. In the event of a fire, these cables emit minimal smoke and no toxic halogen gases, reducing risks to passengers and crew while maintaining visibility for evacuation and firefighting efforts. Compliant with IEC 60092-352, these cables are a cornerstone of electrical installations on all types of commercial vessels, from cargo ships to luxury cruise liners, ensuring compliance with stringent maritime safety regulations.

International Standards: Ensuring Safety and Reliability

The reliability of marine cables is underpinned by adherence to rigorous international standards, ensuring they meet the specific demands of maritime applications. The 150/250V XLPE insulated, LSOH sheathed cables comply with several key IEC standards:

IEC 60092-350/351/376/359: These standards govern the design, construction, and testing of electrical installations and cables for ships. IEC 60092-350 outlines general requirements, while IEC 60092-351 specifies insulation materials, IEC 60092-376 addresses cables for control and instrumentation circuits, and IEC 60092-359 details sheathing materials.

IEC 60332-1 and IEC 60332-3-22: These standards ensure flame-retardant properties. IEC 60332-1 tests single cables for flame propagation, while IEC 60332-3-22 evaluates bunched cables, critical for installations where multiple cables are routed together.

IEC 60754-1/2: These standards confirm that the cables are halogen-free, ensuring no toxic halogen gases are released during combustion.

IEC 61034: This standard measures smoke emission, ensuring low smoke production to maintain visibility in fire scenarios.

Why These Cables Matter: Safety and Efficiency at Sea

The importance of these cables extends beyond their technical specifications. In the maritime industry, safety is non-negotiable. The flame-retardant and LSOH properties of these cables significantly reduce risks during fire incidents, a critical consideration on passenger ships carrying thousands of people. The low smoke emission ensures that escape routes remain visible, while the absence of halogen gases prevents toxic exposure, protecting both passengers and crew.

Moreover, the cables’ robust construction ensures long-term reliability in harsh marine environments. The combination of stranded copper conductors, XLPE insulation, and overall screening minimises signal loss and interference, ensuring that critical systems such as navigation, engine control, and communication operate flawlessly. The ability to withstand temperatures from -30°C to +80°C and resist corrosion from saline environments further enhances their suitability for global maritime operations.

From an operational perspective, the variety of configurations allows ship designers and engineers to select cables tailored to specific systems, optimising performance and reducing installation costs. The compact design and flexible bending radius facilitate installation in tight spaces, such as the confined compartments of a ship, while the lightweight construction minimises the overall weight of the vessel, contributing to fuel efficiency.

The 150/250V XLPE insulated, LSOH sheathed, overall screened, flame-retardant instrumentation and control cables are more than just components—they are the lifelines of modern ships. Their sophisticated design, adherence to international standards, and robust construction make them indispensable for safe and efficient maritime operations. From ensuring clear communication in the bridge to powering critical control systems in the engine room, these cables enable ships to navigate the world’s oceans with confidence.

As maritime technology advances, these cables will continue to evolve, meeting the demands of increasingly complex systems while maintaining the highest standards of safety and reliability. For shipbuilders, operators, and passengers alike, these cables are a testament to the power of engineering to overcome the challenges of the sea, ensuring that vessels remain safe, efficient, and ready for the journey ahead.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430