Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

20kV DC Screened Silicone Wire

Applications

The single core cables are suitable for high-voltage cabinet, power system, high voltage electric machineries, television receivers, transformers, high-voltage cables for electronic instruments, etc.

Rated Voltage

20kV

Construction

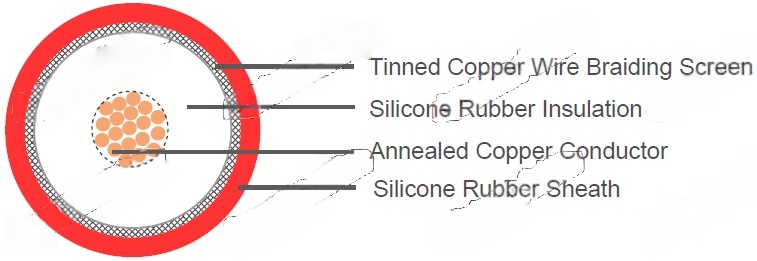

Conductor : Annealed copper conductor, class 5.

Insulation : Silicone rubber.

Screen : Tinned copper wire braiding.

Sheath : Silicone rubber.

Color Code

Red, (other colours upon request).

Physical Properties

Operating Temperature : -45°C - 180°C

Dimension Data

Part NO. | Conductor | Approx. Overall Diameter | ||

|---|---|---|---|---|

No. of Core × Cross Section | No./Nominal Diameter of Strands | Nominal Diameter | ||

| mm² | No./mm | mm | mm |

1x0.20 | 7/0.20 | 0.6 | 5.7 | |

1x0.35 | 19/0.16 | 0.8 | 5.9 | |

1x0.50 | 16/0.2 | 0.94 | 6.1 | |

1x0.75 | 24/0.2 | 1.2 | 7.3 | |

1x1.0 | 32/0.2 | 1.34 | 7.5 | |

1x1.5 | 30/0.25 | 1.6 | 8.1 | |

1x2.5 | 49/0.25 | 2.1 | 9.0 | |

1x4.0 | 56/0.3 | 2.61 | 10.0 | |

1x6.0 | 84/0.3 | 3.21 | 10.8 | |

Introduction

In the heart of South Africa's dynamic energy sector, where the demand for reliable power clashes with extreme environmental challenges, innovative technologies like 20kV DC screened silicone wires are emerging as game-changers. These high voltage DC silicone rubber cables, designed to withstand temperatures from -45°C to 180°C, represent a blend of engineering prowess and practical utility. From powering massive mining operations in the depths of Gauteng's gold mines to supporting the integration of renewable energy in the sun-baked Northern Cape, these cables are pivotal in ensuring efficient, safe electricity transmission.

South Africa's electricity landscape is marked by its reliance on coal-fired power stations operated by Eskom, coupled with a growing push towards renewables under the Renewable Energy Independent Power Producer Procurement Programme (REIPPPP). With load-shedding a persistent issue and the need for grid modernisation, understanding specialised cables like these is crucial.

Understanding 20kV DC Screened Silicone Wires

At their core, 20kV DC screened silicone wires are single-core cables engineered for high-voltage direct current (DC) applications. Rated at 20 kilovolts (kV), they are optimised for scenarios where stable, high-power transmission is essential without the losses associated with alternating current (AC) systems. Unlike traditional PVC-insulated cables, these utilise silicone rubber for insulation and sheathing, providing exceptional flexibility and resistance to extreme conditions.

The "screened" aspect refers to a tinned copper wire braiding that acts as an electromagnetic shield, minimising interference in sensitive electronic environments. This makes them ideal for integration into power systems where electromagnetic compatibility is key. In popular terms, imagine these cables as the robust veins of a high-tech organism, carrying life-giving energy through harsh terrains without faltering.

In South Africa, where temperatures can plummet in winter nights or soar in summer deserts, such resilience is invaluable. These cables align with standards like those from the South African National Standards (SANS), ensuring compliance in industries governed by strict safety regulations.

Key Properties and Advantages

What sets 20kV DC screened silicone wires apart is their operational temperature range: -45°C to 180°C. This exceeds many conventional cables, making them suitable for South Africa's varied climates, from the freezing Highveld winters to the scorching Kalahari summers.

Electrically, the 20kV rating supports high-voltage DC transmission, reducing energy losses over distances compared to AC. The screening minimises noise, ensuring clean signals in instruments and machineries. Mechanically, their flexibility (class 5 conductor) allows easy routing in tight spaces, reducing installation time and costs.

Advantages include longevity – silicone's resistance to ageing extends service life – and safety, as it doesn't emit toxic halogens when burned. Economically, while initial costs may be higher than PVC alternatives, lower maintenance and downtime offset this, especially in high-stakes sectors like mining.

Environmentally, these cables contribute to greener practices by enabling efficient renewable integration, aligning with South Africa's carbon reduction goals under the Paris Agreement.

Applications in Various Industries

These high voltage DC silicone rubber cables find homes in diverse settings. In power systems, they connect high-voltage cabinets and transformers, ensuring reliable distribution. For electric machineries, their flexibility powers mobile equipment like cranes or pumps.

In electronics, they're used in television receivers and instruments requiring shielded high-voltage lines. Beyond the specs, imagine them in medical scanners or industrial robots, where precision is paramount.

In South Africa, applications extend to renewable energy, where they link inverters in solar farms, and mining, powering underground drills. Their EMI shielding is crucial in data-heavy environments like smart grids.

In-Depth Analysis: Multiple Perspectives

Technical Perspective: These cables excel in DC systems due to lower corona losses and simpler insulation. The class 5 conductor offers bend radii as low as 6x diameter, ideal for dynamic applications. However, proper termination is key to avoid partial discharges.

Economic Perspective: Initial costs (R500-R1,000 per metre) are offset by durability; in mining, ROI is achieved in 18 months via reduced failures. In renewables, they lower levelised cost of energy (LCOE) by enabling efficient integration, as seen in CSP projects where LCOE drops to 5-8 c/kWh.

Environmental Perspective: Silicone's non-toxic nature reduces ecological impact. In SA, they support the shift to renewables, cutting CO₂ emissions – Eskom's coal plants emit 200 Mt annually. Their longevity minimises waste, promoting circular economy principles.

Challenges include supply chain dependencies on imports, but local manufacturers like CBI Electric are ramping up production.

Frequently Asked Questions

What is the main advantage of silicone rubber in these cables?

Silicone rubber provides superior thermal and chemical resistance, allowing operation in extreme conditions common in South African industries.

Are these cables suitable for outdoor use in South Africa?

Yes, their UV and ozone resistance makes them ideal for exposed installations, like in Northern Cape solar farms.

How do they compare to PVC cables?

They offer better temperature tolerance and flexibility but at a higher cost; however, they're safer in fire-prone areas like mines.

Can colours be customised?

Absolutely, though red is standard; other colours are available for identification in complex systems.

What maintenance is required?

Minimal – regular visual inspections for abrasion, leveraging their durable construction.

Are they compliant with South African standards?

They align with SANS requirements for high-voltage applications, ensuring safety in regulated sectors.

20kV DC screened silicone wires and high voltage DC silicone rubber cables are more than components; they're enablers of South Africa's energy future. From bolstering mining productivity to accelerating renewable adoption, their versatility addresses pressing challenges like grid instability and climate change. As Eskom and private sectors invest in modernisation, these innovations promise a brighter, more sustainable horizon. With ongoing advancements, they could play a starring role in achieving the country's 2030 renewable targets, powering progress one wire at a time.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430