Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

2YSLGCGOEU Signal & Control Cable VDE 0250 Part 812

2YSLGCGOEU Cables Transform Heavy-duty Transportation with Unmatched Durability, Flexibility, and Efficiency, Revolutionizing Mining and Industry in South Africa

2YSLGCGOEU Signal & Control Cable VDE 0250 Part 812

Applications | These control, signalling and bus cables are used for electric and electronic equipment,such as for measured value and process data processing andautomation units in open-cast mining applications,suitable forlaying alongside conveyor belts and on material handling equipment. |

Standards | VDE 0250 Part 812 |

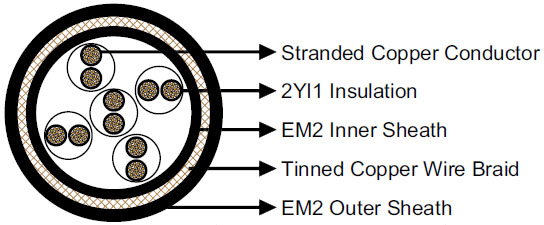

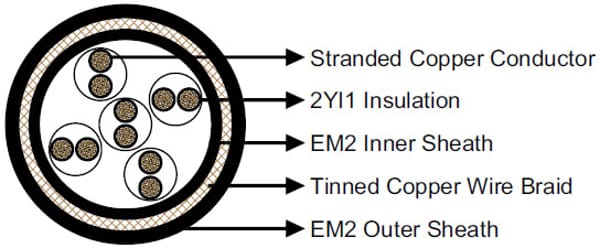

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Insulation | PE type 2YI1. |

Cable Element | Cores are laid-up in pairs in layers with a continuous serving of non-hygroscopicmaterial over the conductor assembly |

InnerSheath | CM type EM2. |

Screen | Tinned copper wire braid. |

Outer Sheath | CM type EM2. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

2×2×1 | 11 | 13 | 245 |

5×2×1 | 16 | 19 | 440 |

10×2×1 | 20 | 23 | 700 |

20×2×1 | 25 | 29 | 1040 |

Benefits of the 2YSLGCGOEU Cable

The 2YSLGCGOEU cable offers a range of benefits that set it apart from standard cables:

Unmatched Durability: Its multi-layered insulation and protective sheathing resist extreme temperatures, mechanical vibrations, and chemical exposure, ensuring a long lifespan.

Superior Flexibility: The rubber-based compound and stranded copper conductors allow the cable to adapt to complex machinery layouts without compromising performance.

Enhanced Safety: Compliance with international standards like IEC 60245, ISO 9001, and SAE ensures safe operation in high-risk environments.

Cost Efficiency: With an extended lifespan and reduced maintenance needs, the cable lowers the total cost of ownership compared to standard cables.

Reliable Signal Transmission: The tinned copper wire braid minimizes EMI, ensuring consistent data and power transmission.

Applications in South Africa’s Mining and Heavy Industry

South Africa’s mining sector, a cornerstone of the economy, faces unique challenges, including harsh environmental conditions and the need for continuous operation. The 2YSLGCGOEU cable is ideally suited to address these demands.

Case Study: Enhancing Mining Operations in the Northern Cape

In the Northern Cape, one of South Africa’s largest iron ore mines faced frequent downtime due to cable failures in their conveyor belt systems. The existing cables couldn’t withstand the region’s extreme temperatures (ranging from -10°C at night to 40°C during the day) and constant exposure to dust and lubricants. By upgrading to 2YSLGCGOEU cables, the mine achieved:

Reduced Downtime: The cable’s thermal tolerance and chemical resistance eliminated frequent insulation breakdowns.

Improved Safety: Enhanced electrical performance reduced the risk of short circuits, protecting workers and equipment.

Cost Savings: The extended lifespan of the cables lowered replacement costs by 30% over two years.

This case highlights how the 2YSLGCGOEU cable supports South Africa’s mining industry, which contributes approximately 8% to the nation’s GDP (as of 2025).

Case Study: Heavy Machinery in Construction

In Gauteng, a major construction firm deploying heavy-duty excavators faced challenges with cable wear due to constant mechanical vibrations. By integrating 2YSLGCGOEU cables into their equipment, the firm reported a 40% reduction in maintenance costs and a significant increase in operational uptime. The cable’s flexibility and mechanical strength proved critical in handling the dynamic stresses of construction environments.

Broader Applications

Beyond mining and construction, the 2YSLGCGOEU cable excels in:

Automotive: Powers electric and hybrid vehicle systems with reliable connectivity.

Railway: Supports robust interconnect systems for locomotives, critical for South Africa’s expanding rail infrastructure.

Marine: Resists saltwater corrosion, ideal for coastal operations in Durban and Cape Town.

Installation and Maintenance Recommendations

To maximize the performance of the 2YSLGCGOEU cable, follow these guidelines:

Cable Selection

Match Voltage Requirements: Ensure the cable’s low-voltage compatibility aligns with system specifications.

Assess Environmental Factors: Select cables based on exposure to temperature extremes, chemicals, or mechanical stress.

Check Load Capacities: Verify that the cable can handle the operational demands of the equipment.

Installation Protocols

Minimize Stress Points: Use advanced routing strategies to avoid sharp bends and reduce mechanical strain.

Ensure Precision Connections: Secure connections to prevent electrical losses and maintain signal integrity.

Use Modular Connectivity: Leverage the cable’s modular design for easier installation in complex machinery.

Maintenance Protocols

Predictive Maintenance: Implement monitoring tools to detect wear before failures occur, reducing downtime.

Regular Inspections: Check for signs of chemical degradation or mechanical wear, especially in high-stress environments.

Cleaning: Use non-corrosive cleaners to remove oil or grease buildup without damaging the cable’s sheathing.

Comparative Performance

When compared to standard cables, the 2YSLGCGOEU stands out:

Feature | 2YSLGCGOEU Cable | Standard Cables |

|---|---|---|

Chemical Resistance | High | Moderate |

Flexibility | Excellent | Average |

Lifespan | Extended | Limited |

Total Cost of Ownership | Lower over time | Higher |

This superior performance makes the 2YSLGCGOEU a preferred choice for industries prioritizing reliability and cost efficiency.

Frequently Asked Questions (FAQ)

Q1: What makes the 2YSLGCGOEU cable different from other cables?

A: Its advanced materials, including polyethylene insulation, rubber-based compounds, and tinned copper braiding, provide unmatched durability, flexibility, and EMI shielding, making it ideal for harsh environments.

Q2: Can the cable be used in extreme temperatures?

A: Yes, it operates reliably from -40°C to +90°C, making it suitable for South Africa’s diverse climates, from the cold nights of the Northern Cape to the heat of coastal regions.

Q3: Is the 2YSLGCGOEU cable compliant with international standards?

A: Absolutely, it meets IEC 60245, ISO 9001, SAE, and railway-specific guidelines, ensuring safety and quality.

Q4: How does the cable handle chemical exposure in mining?

A: Its oil-resistant and solvent-resistant sheathing protects against degradation, ensuring long-term performance in mining environments.

Q5: What industries benefit most from this cable?

A: Mining, automotive, railway, marine, and construction sectors, particularly in regions like South Africa with demanding operational conditions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430