Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

300/500V LSZH Insulated Non-Sheathed Power Cables: Safety and Efficiency in Modern Electrical Systems

300/500V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS EN 50525-3-31

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

CABLE CONSTRUCTION

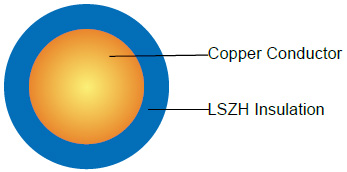

Conductor : Copper conductor according to BS EN 60228 class 1/2/5.

Insulation : Thermoplastic compound of type TI 7 to EN 50363-7.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bi-colours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 70°C

Maximum short circuit temperature (5 Seconds) : 160°C

Minimum bending radius : 4 x Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX100 05Z1-U/R/K | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

1×0.50 | 1 | 0.6 | 1.9 | 2.3 | 9.4 |

1×0.75 | 1 | 0.6 | 2.1 | 2.5 | 12.2 |

1×1.0 | 1 | 0.6 | 2.2 | 2.7 | 15.4 |

1×0.50 | 2 | 0.6 | 2.0 | 2.4 | 10.1 |

1×0.75 | 2 | 0.6 | 2.2 | 2.6 | 13.0 |

1×1.0 | 2 | 0.6 | 2.3 | 2.8 | 16.8 |

1×0.50 | 5 | 0.6 | 2.1 | 2.5 | 9.9 |

1×0.75 | 5 | 0.6 | 2.2 | 2.7 | 13.3 |

1×1.0 | 5 | 0.6 | 2.4 | 2.8 | 16.2 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 70°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor Cross-Sectional Area | Single-phase a.c. | Three-phase a.c. |

|---|---|---|

mm² | A | A |

0.5 | 3 | 3 |

0.75 | 6 | 6 |

1.0 | 10 | 10 |

Note: These values apply to the majority of cases. Further information should be sought in unusual cases eg.: (i) When high ambient temperatures are involved, ie. above 30°C (ii) Where long lengths are used (iii) Where ventilation is restricted (iv) Where the cords are used for other purposes, ego internal wiring of apparatus. | ||

Voltage Drop (Per Amp Per Meter)

Conductor cross-sectional area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | |||||

|---|---|---|---|---|---|---|---|---|

Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | |||||

Cables touching | Cables spaced* | Cables touching, Trefoil | Cables touching, flat | Cables spaced*, flat | ||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

0.5 | 93 | 93 | 93 | 93 | 80 | 80 | 80 | 80 |

0.75 | 62 | 62 | 62 | 62 | 54 | 54 | 54 | 54 |

1.0 | 46 | 46 | 46 | 46 | 40 | 40 | 40 | 40 |

What Are LSZH Insulated, Non-Sheathed Power Cables?

LSZH insulated, non-sheathed power cables are single-core cables designed to operate at a voltage rating of 300/500V, meaning they can handle up to 300 volts between phase and earth and 500 volts between phases. The term "LSZH" refers to low smoke zero halogen, a material property that ensures the cables emit minimal smoke and no toxic halogen gases when exposed to fire. Unlike traditional cables that might release corrosive gases or dense smoke, LSZH cables prioritize safety in environments where human lives and sensitive equipment are at stake.

The "non-sheathed" aspect indicates that these cables lack an outer protective sheath, relying solely on their insulation layer for protection. This design makes them lightweight and flexible, ideal for specific applications where additional sheathing is unnecessary or provided by external conduit systems. Adhering to BS EN 50525-3-31, a European standard for low-voltage cables, these cables meet rigorous performance and safety criteria, ensuring reliability in demanding conditions.

Applications of LSZH Power Cables

The versatility of 300/500V LSZH insulated, non-sheathed power cables makes them suitable for a wide range of applications, particularly in environments where fire safety is a priority. These cables are commonly used in:

Power Stations: Their ability to withstand high temperatures and resist fire propagation ensures safe and reliable power distribution in critical infrastructure.

Mass Transit Systems: Underground passenger systems, such as subways, rely on LSZH cables to minimize smoke and toxic gas emissions, protecting commuters during emergencies.

Airports: High-traffic areas with stringent safety regulations benefit from the cables' fire-retardant properties.

Petrochemical Plants: In environments with flammable substances, LSZH cables reduce the risk of fire escalation.

Hotels, Hospitals, and High-Rise Buildings: These settings prioritize occupant safety, making LSZH cables essential for emergency lighting, fire alarms, and power systems.

Standards and Fire Performance

The design of LSZH insulated, non-sheathed power cables complies with BS EN 50525-3-31, ensuring consistency in quality and performance. Additionally, these cables meet several international fire safety standards, which are critical for their intended applications:

Flame Retardance: Tested under IEC 60332-1-2 and EN 60332-1-2, the cables resist burning when exposed to a single vertical flame, preventing the spread of fire along the cable.

Reduced Fire Propagation: According to IEC 60332-3-24 and EN 60332-3-24, bundled cables demonstrate reduced fire spread in vertically mounted configurations, crucial for installations in confined spaces.

Halogen-Free: Per IEC 60754-1 and EN 50267-2-1, the cables emit no halogen gases, which are toxic and corrosive, ensuring safer evacuation during fires.

No Corrosive Gas Emission: As per IEC 60754-2 and EN 50267-2-2, the cables produce minimal acidic gases, protecting both people and equipment.

Minimum Smoke Emission: Tested under IEC 61034-2 and EN 61034-2, the cables generate low smoke, improving visibility in fire scenarios.

Advantages of LSZH Power Cables

The adoption of 300/500V LSZH insulated, non-sheathed power cables offers several advantages:

Enhanced Safety: The low smoke and zero halogen properties significantly reduce risks during fire incidents, protecting lives and property.

Environmental Responsibility: By eliminating halogen emissions, these cables minimize environmental impact, aligning with sustainable building practices.

Versatility: With options for UV, hydrocarbon, oil, anti-rodent, and anti-termite resistance, the cables can be customized for diverse environments.

Compact Design: The non-sheathed construction reduces weight and bulk, simplifying installation in confined spaces or conduit systems.

Compliance with Standards: Adherence to BS EN 50525-3-31 and international fire safety standards ensures reliability and regulatory compliance.

Conclusion

300/500V LSZH insulated, non-sheathed power cables to BS EN 50525-3-31 represent a pinnacle of safety and efficiency in electrical engineering. Their low smoke, zero halogen properties, combined with robust construction and compliance with stringent standards, make them indispensable in environments where fire safety is paramount. From power stations to high-rise buildings, these cables deliver reliable performance while prioritizing human safety and environmental responsibility. As technology advances and safety regulations evolve, LSZH cables will continue to play a vital role in shaping the future of electrical systems, ensuring that infrastructure remains safe, efficient, and sustainable.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430