Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

300/500V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core): Standing Out for Their Specialized Design Tailored for High-safety Environments

300/500V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

FTX100 05Z-U/K (CU/LSZH 300/500V Class 1/5)

BS Code: 2491B

HAR Code: H05Z-U/K

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS EN 50525-3-41(formerly BS 7211)

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

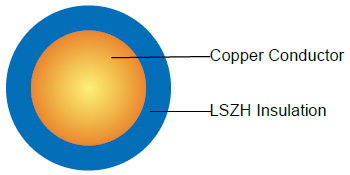

CABLE CONSTRUCTION

Conductor : Copper conductor according to BS EN 60228 class 1/2/5.

Insulation : Crosslinked polyolefin material type EI 5 according to EN 50363-5.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bi-colours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 4 x Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX100 05Z-U/K | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

1×0.50 | 1 | 0.6 | 1.9 | 2.4 | 9.4 |

1×0.75 | 1 | 0.6 | 2.1 | 2.6 | 12.2 |

1×1.0 | 1 | 0.6 | 2.2 | 2.8 | 15.4 |

1×0.50 | 5 | 0.6 | 2.1 | 2.6 | 9.9 |

1×0.75 | 5 | 0.6 | 2.2 | 2.8 | 13.3 |

1×1.0 | 5 | 0.6 | 2.4 | 2.9 | 16.2 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor cross-sectional area | Single-phase a.c. | Three-phase a.c. |

|---|---|---|

mm² | A | A |

0.5 | 3 | 3 |

0.75 | 6 | 6 |

1.0 | 10 | 10 |

Note: These values apply to the majority of cases. Further information should be sought in unusual cases eg.: (i) When high ambient temperatures are involved, ie. above 30°C (ii) Where long lengths are used (iii) Where ventilation is restricted (iv) Where the cords are used for other purposes, ego internal wiring of apparatus. | ||

Voltage Drop (Per Amp Per Meter)

Conductor cross-sectional area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | |||||

|---|---|---|---|---|---|---|---|---|

Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | |||||

Cables touching | Cables spaced* | Cables touching, Trefoil | Cables touching, flat | Cables spaced*, flat | ||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

0.5 | 101 | 101 | 101 | 101 | 87 | 87 | 87 | 87 |

0.75 | 68 | 68 | 68 | 68 | 59 | 59 | 59 | 59 |

1.0 | 50 | 50 | 50 | 50 | 44 | 44 | 44 | 44 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

What Are 300/500V LSZH Insulated, Non-Sheathed Power Cables?

LSZH insulated, non-sheathed power cables are designed to operate at a voltage rating of 300/500V, meaning they can handle up to 300 volts between phase and earth and 500 volts between phases. The "non-sheathed" aspect indicates they lack an outer protective sheath, making them suitable for applications where they are installed within protective conduits or trunking. The defining feature of these cables is their Low Smoke Zero Halogen insulation, which minimizes toxic gas emissions and smoke production in the event of a fire, a critical factor in densely populated or sensitive environments.

The cables adhere to the BS EN 50525-3-41 standard (formerly BS 7211), ensuring compliance with rigorous European safety and performance benchmarks. They are also harmonized under the HAR code H05Z-U/K, indicating their suitability for use across European markets. The conductor, made of copper, complies with BS EN 60228 and can be class 1 (solid), class 2 (stranded), or class 5 (flexible), offering versatility for various installation needs. The insulation, crafted from crosslinked polyolefin material (type EI 5 per EN 50363-5), provides excellent thermal and electrical properties, with optional enhancements like UV resistance, hydrocarbon resistance, and anti-rodent features.

Fire Safety: The Heart of LSZH Technology

One of the standout features of LSZH cables is their fire performance, which is paramount in environments where human safety is non-negotiable. These cables are engineered to meet stringent fire safety standards, including:

Flame Retardance: Tested under IEC 60332-1-2 and EN 60332-1-2, LSZH cables resist flame propagation in single vertical wire tests, reducing the risk of fire spreading.

Halogen-Free: As per IEC 60754-1 and EN 50267-2-1, the cables emit no halogen gases when exposed to fire, preventing the release of toxic fumes that could harm occupants or damage equipment.

No Corrosive Gas Emission: According to IEC 60754-2 and EN 50267-2-2, the cables produce minimal corrosive gases, protecting sensitive electronics and infrastructure.

Low Smoke Emission: Compliant with IEC 61034-2 and EN 61034-2, these cables emit minimal smoke, ensuring better visibility for evacuation and firefighting efforts.

Applications: Where LSZH Cables Shine

The versatility of 300/500V LSZH insulated, non-sheathed power cables makes them a preferred choice across various industries. Their primary applications include:

Power Stations: These cables provide reliable power distribution in environments with high electrical demands, ensuring safety under extreme conditions.

Mass Transit Systems: Underground passenger systems benefit from the cables’ low smoke and halogen-free properties, enhancing passenger safety during emergencies.

Airports: With large crowds and critical infrastructure, airports rely on LSZH cables to maintain operational integrity and safety.

Petrochemical Plants: The cables’ optional hydrocarbon resistance makes them suitable for harsh chemical environments.

Hotels and Hospitals: These settings prioritize occupant safety, leveraging LSZH cables to minimize fire-related risks.

High-Rise Buildings: The cables’ flame-retardant properties are crucial in tall structures where fire evacuation can be challenging.

Advantages of LSZH Cables Over Traditional Options

Compared to traditional PVC-insulated cables, LSZH cables offer several advantages:

Enhanced Safety: The absence of halogens and low smoke emission make LSZH cables safer in fire-prone environments.

Environmental Benefits: Halogen-free materials reduce environmental impact, aligning with green building standards.

Durability: Crosslinked polyolefin insulation provides superior resistance to heat, chemicals, and mechanical stress.

Versatility: Optional features like UV or hydrocarbon resistance expand their usability across diverse applications.

The 300/500V LSZH insulated, non-sheathed power cables to BS EN 50525-3-41 represent a pinnacle of safety and performance in electrical engineering. Their halogen-free, low-smoke properties, combined with robust thermal and electrical characteristics, make them indispensable in high-stakes environments like hospitals, airports, and power stations. By understanding their construction, applications, and performance metrics, engineers and facility managers can make informed decisions to enhance safety and efficiency. As technology evolves, LSZH cables will continue to power the future, ensuring that safety and sustainability go hand in hand in our increasingly electrified world.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430