Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

Unveiling the Power of 300/500V Mica+LSZH Insulated Non-Sheathed Cables: A Deep Dive into Safety and Performance

300/500V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

FFX100 05mZ-U/K (CU/MGT+LSZH 300/500V Class 1/5)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS EN 50525-3-41(formerly BS 7211)

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

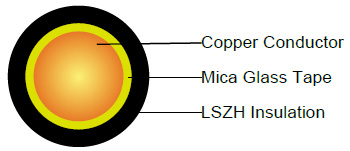

CABLE CONSTRUCTION

Conductor : Copper conductor according to BS EN 60228 class 1/5.

Fire Barrier : Mica glass tape.

Insulation : Crosslinked polyolefin material type EI 5 according to EN 50363-5.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bi-colours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 4 x Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX100 05mZ-U/K | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

1×0.5 | 1 | 0.6 | 2.9 | 3.4 | 13.5 |

1×0.75 | 1 | 0.6 | 3.1 | 3.6 | 16.5 |

1×1.0 | 1 | 0.6 | 3.2 | 3.8 | 19.7 |

1×0.5 | 5 | 0.6 | 3.1 | 3.6 | 14.2 |

1×0.75 | 5 | 0.6 | 3.2 | 3.8 | 17.7 |

1×1.0 | 5 | 0.6 | 3.4 | 3.9 | 20.7 |

ELECTRICAL PROPERTIES

Conductor operating temperature: 90°C

Ambient temperature: 30°C

Current-Carrying Capacities (Amp)

Conductor cross-sectional area | Single-phase a.c. | Three-phase a.c. |

|---|---|---|

mm² | A | A |

0.5 | 3 | 3 |

0.75 | 6 | 6 |

1.0 | 10 | 10 |

Note: These values apply to the majority of cases. further information should be sought in unusual cases eg.: When high ambient temperatures are involved, ie. above 30°C Where long lengths are used Where ventilation is restricted Where the cords are used for other purposes, ego internal wiring of apparatus. | ||

Voltage Drop (Per Amp Per Meter)

Conductor cross-sectional area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | |||||

|---|---|---|---|---|---|---|---|---|

Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | |||||

Cables touching | Cables spaced* | Cables touching, Trefoil | Cables touching, flat | Cables spaced*, flat | ||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

0.5 | 101 | 101 | 101 | 101 | 87 | 87 | 87 | 87 |

0.75 | 68 | 68 | 68 | 68 | 59 | 59 | 59 | 59 |

1.0 | 50 | 50 | 50 | 50 | 44 | 44 | 44 | 44 |

What Are 300/500V Mica+LSZH Cables?

The 300/500V Mica+LSZH insulated, non-sheathed power cables are single-core cables designed to operate at voltage ratings of 300V (phase-to-earth) and 500V (phase-to-phase). The term "Mica+LSZH" refers to their construction, which combines a mica glass tape fire barrier with low smoke zero halogen (LSZH) insulation. These materials ensure the cables maintain circuit integrity under fire conditions while minimizing toxic emissions and smoke, making them ideal for environments where human safety is paramount.

Key Components of the Cable

Conductor: The cables use copper conductors compliant with BS EN 60228, available in Class 1 (solid) or Class 5 (flexible) configurations. Copper is chosen for its excellent conductivity and durability.

Fire Barrier: A layer of mica glass tape provides exceptional fire resistance, allowing the cable to maintain functionality during a fire, a critical feature for emergency systems.

Insulation: The cables are insulated with crosslinked polyolefin material (type EI 5) per EN 50363-5, which offers high thermal stability and low smoke emission. Optional features like UV resistance, hydrocarbon resistance, oil resistance, and anti-rodent/anti-termite properties can be added for specific applications.

Color Coding: Available in a range of colors (black, blue, brown, grey, orange, pink, red, turquoise, violet, white, green, yellow, and bi-color combinations), these cables allow for easy identification in complex wiring systems.

Standards and Fire Performance

The BS EN 50525-3-41 standard, adapted from the former BS 7211, governs the design of these cables, ensuring they meet rigorous safety and performance criteria. Their fire performance is a standout feature, making them suitable for environments where fire safety is non-negotiable.

Fire Performance Characteristics

Circuit Integrity: Compliant with IEC 60331-21 and BS 6387, these cables can withstand fire for extended periods, ensuring that critical systems like fire alarms and emergency lighting remain operational.

Flame Retardance: Tested to IEC 60332-1-2 and EN 60332-1-2, the cables resist flame propagation, reducing the risk of fire spreading.

Halogen-Free: Per IEC 60754-1 and EN 50267-2-1, the LSZH insulation emits no halogen gases, which are toxic when burned.

Low Corrosive Gas Emission: Compliant with IEC 60754-2 and EN 50267-2-2, the cables produce minimal corrosive gases, protecting equipment and human health.

Minimum Smoke Emission: Meeting IEC 61034-2 and EN 61034-2, these cables ensure better visibility in fire scenarios, aiding evacuation.

Applications of Mica+LSZH Cables

The versatility of 300/500V Mica+LSZH cables makes them indispensable in high-risk environments. Their ability to maintain circuit integrity and minimize smoke and toxic emissions is critical in:

Power Stations: Ensuring reliable power delivery under extreme conditions.

Mass Transit Systems: Supporting underground passenger systems where fire safety is crucial.

Airports: Powering critical infrastructure like lighting and communication systems.

Petrochemical Plants: Withstanding harsh chemical environments while maintaining safety.

Hotels, Hospitals, and High-Rise Buildings: Protecting occupants by ensuring emergency systems function during fires.

Advantages of Mica+LSZH Cables

The 300/500V Mica+LSZH cables offer several advantages that make them a preferred choice for safety-critical installations:

Enhanced Fire Safety: The combination of mica tape and LSZH insulation ensures the cables maintain circuit integrity and produce minimal smoke and toxic gases during a fire.

Versatility: Available in multiple conductor sizes and classes, with customizable insulation options, these cables can be tailored to specific environmental challenges.

Durability: With a high operating temperature and resistance to short-circuit conditions, the cables are built to last in demanding conditions.

Ease of Installation: The flexible bending radius and color-coded options simplify installation and maintenance.

Compliance with Standards: Adherence to BS EN 50525-3-41 and international fire performance standards ensures reliability and regulatory compliance.

Conclusion

The 300/500V Mica+LSZH insulated, non-sheathed power cables to BS EN 50525-3-41 represent a pinnacle of safety and performance in electrical engineering. Their ability to maintain circuit integrity, resist flame propagation, and minimize smoke and toxic emissions makes them indispensable in high-risk environments like power stations, hospitals, and high-rise buildings. By combining robust construction, compliance with stringent standards, and customizable features, these cables offer a reliable solution for modern electrical systems. As technology evolves, Mica+LSZH cables will likely remain at the forefront of safe and sustainable power distribution, protecting lives and infrastructure in an increasingly connected world.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430