Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-3 Cores)

Unraveling the Power of 300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables for Safe and Reliable Energy Transmission

300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-3 Cores)

FFX200 05mRZ1-U/R (CU/MGT+XLPE/LSZH 300/500V Class 1/2)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS 7211:2012

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

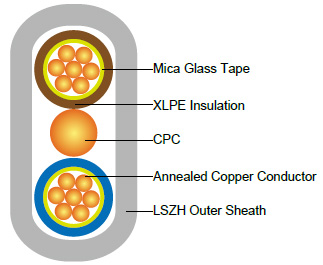

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, solid or stranded according to BS EN 60228 class 1 or class 2.

Fire Barrier : Mica glass tape.

Insulation : XLPE type GP 8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 can be offered as option.

CPC (Circuit Protective Conductor) : Uninsulated copper conductor.

Outer Sheath : Extruded LSZH type LTS 2 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

Twin : Brown and blue or, for 2x1.0 and 2x1.5 cables, brown and brown.

Three cores : Brown, black (centre core) and grey.

Position of CPC :

Twin : Centrally placed between cores in same plane.

Three cores : Centrally placed between black and grey cores in same plane.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX200 05mRZ1-U/R | |||||||

|---|---|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Crosssectional Area of CPC | Class of CPC | Nominal Sheath Thickness | Min. Overall Dimensions | Max. Overall Dimensions | Approx. Weight |

No.×mm² |

| mm | mm² |

| mm | mm | mm | kg/km |

2×1.0 | 1 | 0.7 | 1.0 | 1 | 0.9 | 5.1×9.6 | 6.0×11.2 | 84 |

2×1.5 | 1 | 0.7 | 1.0 | 1 | 0.9 | 5.4×10.1 | 6.3×11.7 | 101 |

2×2.5 | 1 | 0.7 | 1.5 | 1 | 1.0 | 5.9×11.3 | 7.0×12.2 | 136 |

3×1.0 | 1 | 0.7 | 1.0 | 1 | 0.9 | 5.1×13.0 | 6.0×15.1 | 108 |

3×1.5 | 1 | 0.7 | 1.0 | 1 | 0.9 | 5.4×13.7 | 6.3×15.9 | 135 |

3×2.5 | 1 | 0.7 | 1.5 | 1 | 1.0 | 5.9×15.0 | 7.0×17.6 | 190 |

2×1.0 | 2 | 0.7 | 1.0 | 1 | 0.9 | 5.2×9.8 | 6.1×11.4 | 89 |

2×1.5 | 2 | 0.7 | 1.0 | 1 | 0.9 | 5.5×10.3 | 6.4×12.0 | 107 |

2×2.5 | 2 | 0.7 | 1.5 | 1 | 1.0 | 6.0×11.5 | 7.1×13.4 | 141 |

2×4 | 2 | 0.7 | 1.5 | 1 | 1.0 | 6.5×12.4 | 7.7×14.6 | 181 |

2×6 | 2 | 0.7 | 2.5 | 1 | 1.1 | 7.2×14.0 | 8.5×16.6 | 256 |

2×10 | 2 | 0.7 | 4.0 | 2 | 1.2 | 8.3×16.5 | 9.8×19.5 | 406 |

2×16 | 2 | 0.7 | 6.0 | 2 | 1.3 | 9.4×19.0 | 11.1×22.5 | 576 |

3×4 | 2 | 0.7 | 1.5 | 1 | 1.0 | 6.5×17.0 | 7.7×19.9 | 216 |

3×6 | 2 | 0.7 | 2.5 | 1 | 1.1 | 7.2×19.2 | 7.5×22.5 | 311 |

3×10 | 2 | 0.7 | 4.0 | 2 | 1.2 | 8.3×22.5 | 9.8×26.6 | 460 |

3×16 | 2 | 0.7 | 6.0 | 2 | 1.3 | 9.4×25.8 | 11.1×30.6 | 690 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

Conductor cross-sectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core cable*, single-phase a.c. or d.c. | 1 three-or four core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-or four core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-or four core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-or four core cable*, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | A | A | A | A | A | A | A | A |

1.0 | 14.5 | 13 | 17 | 15 | 19 | 17 | 21 | 18 |

1.5 | 18.5 | 16.5 | 22 | 19.5 | 24 | 22 | 26 | 23 |

2.5 | 25 | 22 | 30 | 26 | 33 | 30 | 36 | 32 |

4 | 33 | 30 | 40 | 35 | 45 | 40 | 49 | 42 |

6 | 42 | 38 | 51 | 44 | 58 | 52 | 63 | 54 |

10 | 57 | 51 | 69 | 60 | 80 | 71 | 86 | 75 |

16 | 76 | 68 | 91 | 80 | 107 | 96 | 115 | 100 |

Note: *With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

Conductor cross-sectional area | Two-core cable, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. |

|---|---|---|---|

1 | 2 | 3 | 4 |

mm² | mV/A/m | mV/A/m | mV/A/m |

1.0 | 46 | 46 | 46 |

1.5 | 31 | 31 | 31 |

What Are 300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables?

The 300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables are specialized electrical cables designed to meet stringent safety and performance standards, as outlined in BS 7211:2012. These cables, often referred to as FFX200 05mRZ1-U/R, are constructed with annealed copper conductors (solid or stranded, per BS EN 60228 Class 1 or 2), a mica glass tape fire barrier, XLPE insulation, and an LSZH outer sheath. The combination of these materials ensures durability, fire resistance, and minimal environmental impact during fire events.

Key Components of the Cable

Conductor: Annealed copper, available in solid (Class 1) or stranded (Class 2) configurations, ensures excellent electrical conductivity.

Fire Barrier: Mica glass tape provides circuit integrity under fire conditions, maintaining functionality for critical systems.

Insulation: XLPE (Cross-Linked Polyethylene) type GP 8 or optional EI 5 offers high thermal resistance, with a maximum operating temperature of 90°C and a short-circuit temperature of 250°C.

Circuit Protective Conductor (CPC): An uninsulated copper conductor enhances safety by providing a grounding path.

Outer Sheath: LSZH type LTS 2 minimizes smoke and toxic gas emissions, making it ideal for confined spaces.

The cables are available in twin (2-core) or three-core configurations, with insulation color-coded for easy identification (brown and blue or brown and brown for twins; brown, black, and grey for three cores). The sheath is typically white but can be customized for UV resistance, oil resistance, or anti-rodent properties.

Fire Performance: For Safety

One of the standout features of these cables is their exceptional fire performance, which is critical in high-risk environments like South Africa’s mining sector. The cables comply with rigorous international standards, including:

Circuit Integrity: Tested to IEC 60331-21 and BS 6387, ensuring the cable maintains functionality during fire exposure.

Flame Retardance: Meets IEC 60332-1-2 and EN 60332-1-2 for single vertical wire tests, preventing fire spread.

Reduced Fire Propagation: Complies with IEC 60332-3-24 and EN 60332-3-24 for bundled cables, minimizing fire spread in dense installations.

Halogen-Free: Adheres to IEC 60754-1 and EN 50267-2-1, eliminating toxic halogen gas emissions.

Low Smoke Emission: Meets IEC 61034-2 and EN 61034-2, ensuring visibility in fire scenarios.

Applications in South Africa’s Mining and Heavy Industries

South Africa’s mining sector, a backbone of the country’s economy, relies heavily on robust electrical infrastructure. The 300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables are tailored for such demanding environments, where fire risks, extreme temperatures, and harsh conditions are common.

Case Study 1: Enhancing Safety in South African Gold Mines

In 2024, a leading gold mining company in South Africa’s Witwatersrand Basin upgraded its underground power distribution system with these cables. The mine, located in a region prone to seismic activity and high ambient temperatures, required cables that could withstand both environmental stress and potential fire hazards. The LSZH sheathing was critical in reducing smoke and toxic gas emissions in the confined underground tunnels, ensuring safer evacuation routes during emergencies. The mica fire barrier maintained circuit integrity, allowing critical ventilation and lighting systems to remain operational during a minor fire incident in early 2025, preventing a potential catastrophe.

Case Study 2: Powering Heavy Industry in Mpumalanga

A petrochemical plant in Mpumalanga, a hub for South Africa’s heavy industry, adopted these cables for its power distribution network in 2023. The plant’s high-risk environment, with exposure to hydrocarbons and extreme heat, necessitated cables with optional hydrocarbon-resistant and UV-resistant sheathing. The cables’ ability to operate at 90°C and handle short-circuit temperatures up to 250°C ensured reliable performance, reducing downtime and maintenance costs. The project aligned with South Africa’s push for safer industrial practices, as outlined in recent occupational health and safety regulations.

Benefits of Mica+XLPE Insulated, LSZH Sheathed Cables

Enhanced Safety: The LSZH sheath and mica fire barrier minimize risks in fire-prone environments, protecting both people and infrastructure.

Durability: XLPE insulation ensures long-term performance under high temperatures and mechanical stress.

Versatility: Customizable sheath options (e.g., UV or oil resistance) make the cables adaptable to diverse applications.

Compliance: Adherence to BS 7211 and international fire standards ensures reliability in critical systems.

Environmental Responsibility: Halogen-free materials reduce environmental impact during fire events.

Conclusion

The 300/500V Mica+XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 are a testament to the advancements in electrical engineering, offering unparalleled safety, reliability, and versatility. In South Africa’s mining and heavy industries, these cables address critical challenges, from fire risks to environmental compliance. By integrating cutting-edge materials and adhering to rigorous standards, they ensure uninterrupted power delivery while prioritizing human safety. As industries evolve, these cables will remain a cornerstone of modern infrastructure, powering progress in the face of adversity.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430