Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V PVC Insulated, Non-sheathed Power Cables (Single Core)

300/500V PVC Insulated, Non-sheathed Power Cables (Single Core): Engineered for Durability, Safety, and Efficiency

300/500V PVC Insulated, Non-sheathed Power Cables (Single Core)

FGD100 05V-U/R/K (CU/PVC 300/500V Class 1/2/5)

BS Code: 2491X

HAR Code: H05V-U, H05V-R, H05V-K

APPLICATION

This cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

STANDARDS

Basic design to BS EN 50525-2-31(formerly BS 6004:2000)

FIRE PERFORMANCE

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2 |

VOLTAGE RATING

300/500V

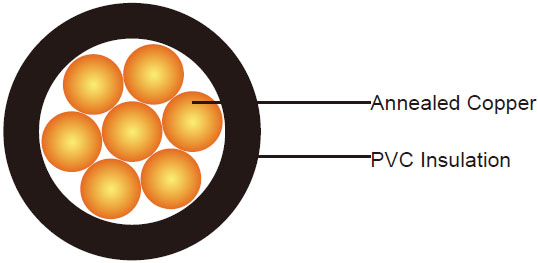

CABLE CONSTRUCTION

Conductor | H05V-U | Class 1 solid copper conductor to BS EN 60228. |

H05V-R | Class 2 stranded copper conductor to BS EN 60228. | |

H05V-K | Class 5 stranded copper conductor to BS EN 60228. | |

Insulation | PVC Type TI 1 according to BS EN 50363-3 | |

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bicolours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C | |

Maximum short circuit temperature (5 Seconds) | 160°C | |

Minimum bending radius | Up to 8mm²: | 4 x overall diameter |

8mm² to 12mm² | 5 x overall diameter | |

Above 12mm² | 6 x overall diameter | |

CONSTRUCTION PARAMETERS

Conductor | FGD100 05V-U/R/K | ||||

|---|---|---|---|---|---|

| No. of Cores x Cross Section | Class of Conductor | Nominal Insulation Thickness | Maximum Overall Diameter | Approx. Weight |

| No.xmm² |

| mm | mm | kg/km |

1x0.50 | 1 | 0.6 | 2.3 | 8 | |

1x0.75 | 1 | 0.6 | 2.5 | 11 | |

1x1.0 | 1 | 0.6 | 2.7 | 14 | |

1x0.50 | 2 | 0.6 | 2.4 | 9 | |

1x0.75 | 2 | 0.6 | 2.6 | 12 | |

1x1.0 | 2 | 0.6 | 2.8 | 14 | |

1x0.50 | 5 | 0.6 | 2.5 | 8 | |

1x0.75 | 5 | 0.6 | 2.7 | 11 | |

1x1.0 | 5 | 0.6 | 2.8 | 13 | |

ELECTRICAL PROPERTIES

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4D1A

Conductor cross-sectional area | PVC insulated types (HD 21) | |

|---|---|---|

single-phase a.c. | three-phase a.c. | |

mm² | A | A |

0.50 | 3 | 3 |

0.75 | 6 | 6 |

1.0 | 10 | 10 |

Note: These values apply to the majority of cases. Further information should be sought in unusual cases eg.: (i) When high ambient temperatures are involved, ie. above 30°C (ii) Where long lengths are used (iii) Where ventilation is restricted (iv) Where the cords are used for other purposes, ego internal wiring of apparatus. | ||

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4D1B

Conductor cross-sectional area | d.c. or single-phase a.c. | Three-phase a.c. |

|---|---|---|

mm² | mV/A/m | mV/A/m |

0.50 | 93 | 80 |

0.75 | 62 | 54 |

1.0 | 46 | 40 |

What Are 300/500V PVC Insulated Non-Sheathed Power Cables?

These cables are single-core, polyvinyl chloride (PVC) insulated wires designed to operate at a voltage rating of 300/500V, meaning they can handle up to 300 volts between phase and earth and 500 volts between phases. The absence of an outer sheath makes them lightweight and flexible, ideal for internal wiring or applications where additional protection is provided by conduit or trunking. They come in three conductor classes:

H05V-U: Class 1 solid copper conductor, offering rigidity for fixed installations.

H05V-R: Class 2 stranded copper conductor, balancing flexibility and strength.

H05V-K: Class 5 stranded copper conductor, highly flexible for dynamic applications.

The cables are insulated with PVC Type TI 1, compliant with BS EN 50363-3, ensuring robust electrical insulation and thermal stability up to 70°C during operation and 160°C during short circuits (up to 5 seconds).

Key Applications in South Africa

The versatility of 300/500V PVC insulated cables makes them indispensable across various sectors. In South Africa, they are particularly prominent in:

Power Stations: Ensuring reliable power distribution within control panels and auxiliary systems.

Mining Operations: Powering equipment in harsh underground environments, such as conveyors and ventilation systems.

Petrochemical Plants: Supporting instrumentation and control circuits in refineries.

High-Rise Buildings and Infrastructure: Used in internal wiring for lighting and power circuits in commercial structures.

Mass Transit Systems: Facilitating safe and efficient electrical systems in underground rail networks.

Advantages of 300/500V PVC Insulated Cables

Versatility: Suitable for a wide range of applications, from fixed installations (H05V-U) to flexible setups (H05V-K).

Cost-Effectiveness: Non-sheathed design reduces material costs, ideal for budget-conscious projects.

Safety: Flame-retardant insulation minimizes fire risks, critical in high-stakes environments like mines.

Ease of Installation: Lightweight and flexible, especially in Class 5 conductors, simplifying complex wiring tasks.

Frequently Asked Questions

1. What does the 300/500V rating mean?

The 300/500V rating indicates the cable’s maximum voltage capacity: 300V between phase and earth, and 500V between phases. This makes it suitable for low-voltage applications in industrial and commercial settings.

2. Why choose non-sheathed cables over sheathed ones?

Non-sheathed cables are lighter, more flexible, and cost-effective, ideal for internal wiring or installations within protective conduits. However, they require additional protection in harsh environments.

3. Are these cables suitable for South Africa’s mining industry?

Yes, their flame-retardant properties, durability, and flexibility make them ideal for mining applications, particularly in control circuits and ventilation systems.

4. How do I select the right conductor class (H05V-U, H05V-R, H05V-K)?

H05V-U: Best for fixed, permanent installations due to its solid conductor.

H05V-R: Suitable for semi-flexible applications requiring moderate movement.

H05V-K: Ideal for dynamic applications with frequent bending, such as in machinery.

5. What standards do these cables comply with?

They adhere to BS EN 50525-2-31 (formerly BS 6004:2000), BS EN 60228 for conductors, BS EN 50363-3 for insulation, and EN 60332-1-2 for flame retardance.

6. Can these cables be used in high-temperature environments?

They operate reliably up to 70°C, but derating is required for ambient temperatures above 30°C, as per BS 7671:2008 guidelines.

The 300/500V PVC insulated, non-sheathed single core power cables are a cornerstone of South Africa’s industrial and infrastructure projects. Their versatility, safety features, and compliance with international standards make them indispensable in mining, heavy industry, and beyond. As South Africa navigates economic and environmental challenges, these cables will continue to power progress, ensuring reliability and safety in critical applications. Whether in the depths of a gold mine or the control room of a renewable energy plant, these cables prove that even the smallest components can have a monumental impact.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430