Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V PVC Insulated, Non-sheathed Power Cables (Single Core 90°C)

Understanding 300/500V PVC Insulated Non-Sheathed Power Cables: Technology, Applications, and South African Use Cases

300/500V PVC Insulated, Non-sheathed Power Cables (Single Core 90°C)

FGD100 05V2-U/R/K (CU/PVC 300/500V Class 1/2/5)

BS Code : 2491XHR

HAR Code : H05V2-U, H05V2-R, H05V2-K

APPLICATION

This cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

STANDARDS

Basic design to BS EN 50525-2-31(formerly BS 6004:2000)

FIRE PERFORMANCE

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2 |

VOLTAGE RATING

300/500V

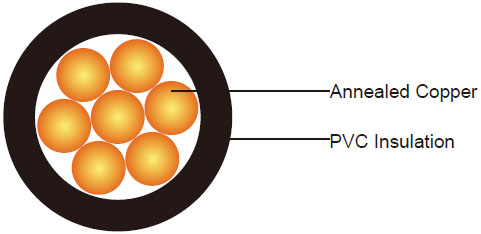

CABLE CONSTRUCTION

Conductor | H05V-U | Class 1 solid copper conductor to BS EN 60228. |

H05V-R | Class 2 stranded copper conductor to BS EN 60228. | |

H05V-K | Class 5 stranded copper conductor to BS EN 60228. | |

Insulation | PVC Type TI 3 according to BS EN 50363-3 | |

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bicolours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 90°C | |

Maximum short circuit temperature (5 Seconds) | 160°C | |

Minimum bending radius | Up to 8mm² | 4 x overall diameter |

| 8mm² to 12mm² | 5 x overall diameter |

| Above 12mm² | 6 x overall diameter |

CONSTRUCTION PARAMETERS

Conductor | FGD100 05V-U/R/K | |||

|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | Nominal Insulation Thickness | Maximum Overall Diameter | Approx. Weight |

No.xmm² |

| mm | mm | kg/km |

1x0.50 | 1 | 0.6 | 2.3 | 8 |

1x0.75 | 1 | 0.6 | 2.5 | 11 |

1x1.0 | 1 | 0.6 | 2.7 | 14 |

1x0.50 | 2 | 0.6 | 2.4 | 9 |

1x0.75 | 2 | 0.6 | 2.6 | 12 |

1x1.0 | 2 | 0.6 | 2.8 | 14 |

1x0.50 | 5 | 0.6 | 2.5 | 8 |

1x0.75 | 5 | 0.6 | 2.7 | 11 |

1x1.0 | 5 | 0.6 | 2.8 | 13 |

ELECTRICAL PROPERTIES

Current-Carrying Capacities (Amp) according to HD516 Table 7 (a)

Conductor cross-sectional area | PVC insulated types (HD 21) | |

|---|---|---|

single-phase a.c. | three-phase a.c. | |

mm² | A | A |

0.50 | 3 | 3 |

0.75 | 6 | 6 |

1.0 | 10 | 10 |

Note: These values apply to the majority of cases. Further information should be sought in unusual cases eg.: (i) When high ambient temperatures are involved, ie. above 30°C (ii) Where long lengths are used (iii) Where ventilation is restricted (iv) Where the cords are used for other purposes, ego internal wiring of apparatus. | ||

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E1B

Nominal Cross Section Area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | |||||

|---|---|---|---|---|---|---|---|---|

Ref. Methods A and B (enclosed in conduit or trunking) | Ref. Methods C, F & G (clipped direct, on trays or in free air) | Ref. Methods A & B (enclosed in conduit or trunking | Ref. Methods C, F & G (clipped direct, on trays or in free air) | |||||

Cables touching | Cables spaced* | Cables touching, Trefoil | Cables touching, Flat | Cables spaced*, Flat | ||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

0.50 | 93 | 93 | 93 | 93 | 80 | 80 | 80 | 80 |

0.75 | 62 | 62 | 62 | 62 | 54 | 54 | 54 | 54 |

1.0 | 46 | 46 | 46 | 46 | 40 | 40 | 40 | 40 |

What Are 300/500V PVC Insulated Non-Sheathed Power Cables?

These cables are single-core, non-sheathed power cables designed for a voltage rating of 300/500V, meaning they can handle up to 300 volts between phase and earth and 500 volts between phases. The PVC (Polyvinyl Chloride) insulation allows them to operate at a maximum temperature of 90°C, making them suitable for environments where heat resistance is critical. The absence of a sheath—a protective outer layer—means these cables are typically used in protected environments, such as within conduits or trunking, to ensure safety and longevity.

The cables come in three conductor classes:

H05V-U: Class 1 solid copper conductor, ideal for fixed installations where minimal flexibility is needed.

H05V-R: Class 2 stranded copper conductor, offering a balance of flexibility and strength.

H05V-K: Class 5 stranded copper conductor, highly flexible for applications requiring frequent bending.

These cables adhere to BS EN 50525-2-31 (formerly BS 6004:2000) standards, ensuring compliance with international safety and performance requirements. Their flame-retardant properties, certified under EN 60332-1-2 (Single Vertical Wire Test), make them a preferred choice in fire-sensitive environments like hospitals, airports, and mass transit systems.

Technical Specifications

Cable Construction

The construction of these cables is straightforward yet robust:

Conductor: Made of copper, meeting BS EN 60228 standards. The conductor class (1, 2, or 5) determines flexibility and application.

Insulation: PVC Type TI 3 (per BS EN 50363-3) provides excellent thermal and electrical insulation, capable of withstanding up to 90°C during operation and 160°C during a short circuit (up to 5 seconds).

Color Code: Available in a wide range of colors (e.g., black, blue, brown, grey, orange, pink, red, turquoise, violet, white, green, yellow, and bicolor combinations), allowing easy identification in complex wiring systems.

Physical and Thermal Properties

Maximum Operating Temperature: 90°C, suitable for high-temperature environments.

Maximum Short Circuit Temperature: 160°C for up to 5 seconds, ensuring safety during electrical faults.

Minimum Bending Radius:

Up to 8mm²: 4 x overall diameter

8mm² to 12mm²: 5 x overall diameter

Above 12mm²: 6 x overall diameter

Construction Parameters

The cables are available in various cross-sectional areas (0.50mm², 0.75mm², 1.0mm²) with corresponding conductor classes. For example:

1 x 0.50mm² (Class 1): Nominal insulation thickness of 0.6mm, maximum overall diameter of 2.3mm, and approximate weight of 8kg/km.

1 x 1.0mm² (Class 5): Nominal insulation thickness of 0.6mm, maximum overall diameter of 2.8mm, and approximate weight of 13kg/km.

Electrical Properties

The current-carrying capacities (per HD516 Table 7a) and voltage drop (per BS 7671:2008 Table 4E1B) are critical for ensuring efficient power delivery:

Current-Carrying Capacities:

0.50mm²: 3A (single-phase and three-phase AC)

0.75mm²: 6A

1.0mm²: 10A

Voltage Drop (per amp per meter):

0.50mm²: 93 mV/A/m (DC and AC, enclosed in conduit)

0.75mm²: 62 mV/A/m

1.0mm²: 46 mV/A/m

These values assume standard conditions (e.g., ambient temperature of 30°C). Adjustments may be needed for high temperatures, long cable lengths, restricted ventilation, or specific applications like internal wiring.

Applications of 300/500V PVC Insulated Cables

These cables are designed for environments requiring reliable, flame-retardant power distribution. Their primary applications include:

Power Stations: Ensuring stable power delivery in high-demand settings.

Mass Transit Systems: Used in underground passenger systems for lighting, signaling, and control systems.

Airports: Powering critical infrastructure like runway lighting and terminal systems.

Petrochemical Plants: Providing safe, heat-resistant wiring in hazardous environments.

Hotels, Hospitals, and High-Rise Buildings: Supporting electrical systems where fire safety is paramount.

The flame-retardant properties and 90°C operating temperature make these cables ideal for installations where safety and reliability are non-negotiable.

Case Studies: South Africa’s Mining and Heavy Industry Sectors

South Africa’s mining and heavy industry sectors are critical to the country’s economy, contributing significantly to GDP and employment. These industries rely heavily on robust electrical infrastructure, where 300/500V PVC insulated non-sheathed power cables play a pivotal role. Below are two case studies highlighting their use in addressing current challenges and trends in South Africa.

Case Study: Enhancing Safety in South African Gold Mines

South Africa is one of the world’s largest gold producers, but its deep-level mines face significant safety challenges, including fire risks and electrical faults. In 2024, a major gold mining company in the Witwatersrand Basin upgraded its underground electrical systems to comply with stricter safety regulations. The company adopted H05V2-K (Class 5) cables for their flexibility and flame-retardant properties, installing them in conduits to power ventilation systems and lighting in confined mine shafts.

The 90°C operating temperature ensured the cables could withstand the heat generated in deep mines, where ambient temperatures often exceed 30°C. The flame-retardant insulation reduced the risk of fire propagation, a critical concern given the history of mine fires in South Africa. By using 1.0mm² cables with a current-carrying capacity of 10A, the company ensured reliable power delivery while minimizing voltage drop over long distances. This upgrade not only improved safety but also reduced downtime caused by electrical failures, boosting productivity by an estimated 5% in 2025.

300/500V PVC insulated non-sheathed power cables (single core, 90°C) are a cornerstone of modern electrical infrastructure, offering reliability, safety, and versatility. Their flame-retardant properties, high-temperature tolerance, and flexible conductor options make them indispensable in power stations, mass transit systems, and industrial settings. In South Africa, these cables are driving safety and efficiency in the mining and heavy industry sectors, as seen in gold mines and coal processing plants. By understanding their technical specifications and applications, engineers and facility managers can make informed decisions to power the future safely and efficiently.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430