Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V PVC Insulated, PVC Sheathed Power Cables to BS 6004 (Single Core)

Exploring 300/500V PVC Insulated, PVC Sheathed Power Cables to BS 6004 Standards

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

STANDARDS

Basic design to BS 6004: 2012

FIRE PERFORMANCE

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2 |

VOLTAGE RATING

300/500V

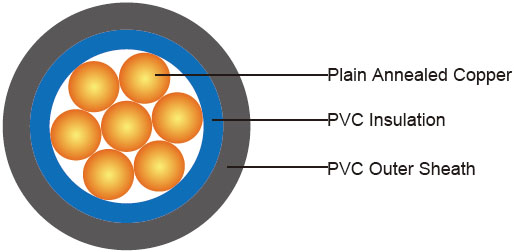

CABLE CONSTRUCTION

Conductor | Annealed copper conductor, class 1 (1.0mm² to 2.5mm²) or class 2 (4mm² to 35mm²) according to BS EN 60228. |

Insulation | PVC Type TI 1 according to BS EN 50363-3. |

Outer Sheath | PVC Type 6 according to BS 7655-4.2. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

COLOUR CODE

Insulation Colour | Brown or blue. |

Sheath Colour | Grey, other colours can be offered upon request. |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C |

Maximum short circuit temperature (5 Seconds) | 160°C |

Minimum bending radius | Up to 10mm² - Fixed: 3 x overall diameter |

| 10mm² to 25mm² - Fixed: 4 x overall diameter |

CONSTRUCTION PARAMETERS

Conductor | FGD300 05VV-U/R | ||||

|---|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Sheath Thickness | Maximum Overall Diameter | Approx. Weight |

No.xmm² |

| mm |

| mm | kg/km |

1x1.0 | 1 | 0.6 | 0.8 | 4.5 | 27 |

1x1.5 | 1 | 0.7 | 0.8 | 5.0 | 36 |

1x2.5 | 1 | 0.8 | 0.8 | 5.7 | 52 |

1x4.0 | 2 | 0.8 | 0.9 | 6.7 | 76 |

1x6.0 | 2 | 0.8 | 0.9 | 7.3 | 100 |

1x10 | 2 | 1.0 | 0.9 | 8.8 | 160 |

1x16 | 2 | 1.0 | 1.0 | 10.1 | 230 |

1x25 | 2 | 1.2 | 1.1 | 12.1 | 340 |

1x35 | 2 | 1.2 | 1.1 | 13.5 | 440 |

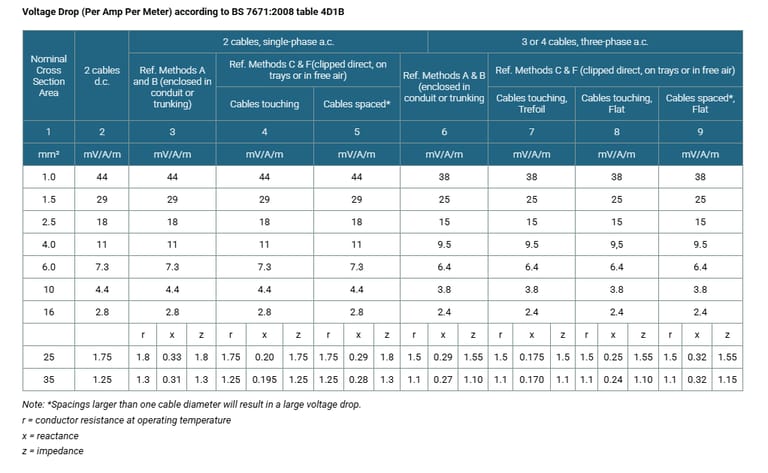

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 70°C |

Ambient Temperature | 30° |

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4D1A

Conductor cross- sectional area | Reference Method A (enclosed in conduit in thermally insulating wall etc) | Reference Method B (enclosed in conduit on a wall or in trunking etc) | Reference Method C (clipped direct) | Reference Method F (in free air or on a perforated cable tray horizontal or vertical etc) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Touching | Spaced by one cable diameter | ||||||||||

2 cables, single-phase a.c. or d.c. | 3 or 4 cables, three-phase a.c. | 2 cables, single-phase a.c. or d.c | 3 or 4 cables, three-phase a.c. | 2 cables, single-phase a.c. or d.c. flat and touching | 3 or 4 cables, three-phase a.c. flat and touching or trefoil | 2 cables, single-phase a.c. or d.c. flat | 3 cables, three-phase a.c. flat | 3 cables, three-phase a.c. trefoil | 2 cables, single-phase a.c. or d.c. or 3 cables three-phase a.c. flat | ||

Horizontal | Vertical | ||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

mm² | A | A | A | A | A | A | A | A | A | A | A |

1.0 | 11.0 | 10.5 | 13.5 | 12.0 | 15.5 | 14 | - | - | - | - | - |

1.5 | 14.5 | 13.5 | 17.5 | 15.5 | 20 | 18 | - | - | - | - | - |

2.5 | 20 | 18 | 24 | 21 | 27 | 25 | - | - | - | - | - |

4.0 | 26 | 24 | 32 | 28 | 37 | 33 | - | - | - | - | - |

6.0 | 34 | 31 | 41 | 36 | 47 | 43 | - | - | - | - | - |

10 | 46 | 42 | 57 | 50 | 65 | 59 | - | - | - | - | - |

16 | 61 | 56 | 76 | 68 | 87 | 79 | - | - | - | - | - |

25 | 80 | 73 | 101 | 89 | 114 | 104 | 131 | 114 | 110 | 146 | 130 |

35 | 99 | 89 | 125 | 110 | 141 | 129 | 162 | 143 | 137 | 181 | 162 |

What Are 300/500V PVC Insulated, PVC Sheathed Power Cables?

The 300/500V PVC insulated, PVC sheathed power cables, compliant with BS 6004:2012, are single-core cables designed for low-voltage applications. The "300/500V" rating indicates their voltage capacity: 300 volts for the phase-to-earth connection and 500 volts for phase-to-phase. These cables are constructed with precision to ensure safety, durability, and performance in demanding environments.

Key Components of the Cable

Conductor: Made from annealed copper, these cables use class 1 conductors (solid) for cross-sections from 1.0mm² to 2.5mm² and class 2 conductors (stranded) for 4mm² to 35mm², adhering to BS EN 60228 standards. Copper’s excellent conductivity ensures minimal energy loss.

Insulation: The conductor is enveloped in PVC Type TI 1, as per BS EN 50363-3, which provides electrical insulation and thermal resistance up to 70°C during operation.

Outer Sheath: A robust PVC Type 6 sheath, compliant with BS 7655-4.2, protects the cable from environmental stressors. Optional enhancements include UV resistance, hydrocarbon resistance, and anti-rodent or anti-termite properties.

Color Coding: Insulation is typically brown or blue, while the sheath is grey, though custom colors are available upon request.

Applications: Powering the Modern World

The versatility of 300/500V PVC insulated, PVC sheathed power cables makes them a go-to choice for a wide range of applications. Their robust design and compliance with stringent safety standards, including TÜV approval, ensure they are suitable for critical infrastructure.

Key Applications

Power Stations: These cables reliably distribute power within generation facilities, ensuring seamless energy flow.

Mass Transit Systems: In underground passenger systems, their flame-retardant properties (meeting EN 60332-1-2 standards) are crucial for safety in confined spaces.

Airports and Petrochemical Plants: The cables’ durability and optional resistance to hydrocarbons make them ideal for harsh industrial environments.

Hotels, Hospitals, and High-Rise Buildings: Their compact design and compliance with fire performance standards (e.g., IEC 60332-1, UL 1581) ensure safe power delivery in densely populated structures.

Standards and Compliance: Ensuring Safety and Reliability

The BS 6004:2012 standard governs the design and performance of these cables, ensuring they meet rigorous safety and quality benchmarks. This British Standard outlines requirements for construction, insulation, and fire performance, aligning with international norms like IEC 60332-1-2 for flame retardance. Compliance with these standards guarantees that the cables can withstand operational stresses while minimizing risks such as fire propagation or electrical faults.

Fire Performance

One of the standout features of these cables is their flame-retardant properties, tested via the single vertical wire test (EN 60332-1-2). This ensures that, in the event of a fire, the cables resist flame spread, a critical factor in high-risk environments like hospitals or transit systems. For enhanced fire safety, low-smoke PVC (LSPVC) options are available, reducing toxic emissions during combustion.

Advantages of PVC Insulated, PVC Sheathed Cables

These cables offer several advantages that make them a preferred choice for engineers and installers:

Durability: The PVC insulation and sheath provide robust protection against mechanical damage, moisture, and chemical exposure.

Fire Safety: Their flame-retardant properties reduce fire risks, making them ideal for public spaces.

Cost-Effectiveness: PVC is an economical material, offering high performance at a relatively low cost.

Versatility: Customizable sheath options allow these cables to adapt to diverse environmental challenges.

Ease of Installation: Their compact design and flexible bending radii simplify installation in constrained spaces.

Conclusion

The 300/500V PVC insulated, PVC sheathed power cables to BS 6004 standards are a cornerstone of modern electrical systems. Their robust construction, compliance with stringent safety standards, and adaptability to diverse applications make them indispensable in powering our world. From their annealed copper conductors to their flame-retardant PVC sheaths, these cables embody the perfect blend of engineering precision and practical utility. As technology advances, these cables will continue to evolve, incorporating sustainable materials and smart features to meet the challenges of tomorrow’s infrastructure.

By understanding the design, applications, and performance of these cables, we gain a deeper appreciation for the unsung heroes that keep our lights on, our buildings powered, and our world connected.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430