Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V PVC Insulated, PVC Sheathed Power Cables to BS EN 50525 (2-5 Cores)

A Deep Dive into 300/500V PVC Insulated, PVC Sheathed Power Cables to BS EN 50525 (2-5 Cores)

300/500V PVC Insulated, PVC Sheathed Power Cables to BS EN 50525 (2-5 Cores)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

STANDARDS

Basic design to BS EN 50525-2-11(formerly BS 6500)

FIRE PERFORMANCE

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2 |

VOLTAGE RATING

300/500V

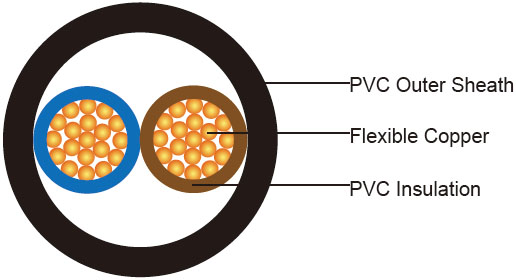

CABLE CONSTRUCTION

Conductor | Flexible copper wire according to EN 60228 class 5. |

Insulation | PVC Type TI 2 according to EN 50363-3. |

Filling | For circular cable having two cores, the space between the cores shall be filled either by separate fillers or by the sheath filling the interstices. For circular cables with three, four or five cores, a centre filler may be used. |

Outer Sheath | PVC Type TM 2 according to EN 50363-4-1. A tape may be applied around the core assembly before application of the sheath. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

COLOUR CODE

Insulation Colour :

Cables and cords with a green-and-yellow cores

No. of cores | Colour of coresb | ||||

Protective | Live | ||||

3 Cores | Yellow/Green | Blue | Brown |

|

|

4 Cores | Yellow/Green | - | Brown | Black | Grey |

4 Coresa | Yellow/Green | Blue | Brown | Black |

|

5 Cores | Yellow/Green | Blue | Brown | Black | Grey |

a : For certain applications only. b : In this table an uninsulated concentric conductor, such as a metallic sheath, armour or screen wire, is not regarded as a core. A concentric conductor is identified by its position and, therefore, need not be identified by colour. | |||||

Cables and cords without a green-and-yellow cores

No. of cores | Colour of coresb | ||||

2 Cores | Blue | Brown |

|

|

|

3 Cores | - | Brown | Black | Grey |

|

3 Coresa | Blue | Brown | Black |

|

|

4 Cores | Blue | Brown | Black | Grey |

|

5 Cores | Blue | Brown | Black | Grey | Black |

a : For certain applications only. b : In this table an uninsulated concentric conductor, such as a metallic sheath, armour or screen wire, is not regarded as a core. A concentric conductor is identified by its position and, therefore, need not be identified by colour. | |||||

Sheath Colour : Black, other colours can be offered upon request.

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C |

Maximum short circuit temperature (5 Seconds) | 160°C |

Minimum bending radius | Up to 12mm² : 3 x overall diameter |

| Above 12mm² : 4 x overall diameter |

CONSTRUCTION PARAMETERS

Conductor | FGD200 05VV-F | ||||

|---|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Sheath Thickness | Maximum Overall Diameter | Approx. Weight |

No.xmm² |

| mm | mm | mm | kg/km |

2x0.75 | 5 | 0.6 | 0.8 | 7.2 | 57 |

2x1.0 | 5 | 0.6 | 0.8 | 7.5 | 65 |

2x1.5 | 5 | 0.7 | 0.8 | 8.6 | 87 |

2x2.5 | 5 | 0.8 | 1.0 | 10.6 | 134 |

2x4.0 | 5 | 0.8 | 1.1 | 12.1 | 174 |

3x0.75 | 5 | 0.6 | 0.8 | 7.6 | 68 |

3x1.0 | 5 | 0.6 | 0.8 | 8.0 | 79 |

3x1.5 | 5 | 0.7 | 0.9 | 9.4 | 111 |

3x2.5 | 5 | 0.8 | 1.1 | 11.4 | 169 |

3x4.0 | 5 | 0.8 | 1.2 | 13.1 | 233 |

4x0.75 | 5 | 0.6 | 0.8 | 8.3 | 84 |

4x1.0 | 5 | 0.6 | 0.9 | 9.0 | 101 |

4x1.5 | 5 | 0.7 | 1.0 | 10.5 | 142 |

4x2.5 | 5 | 0.8 | 1.1 | 12.5 | 211 |

4x4.0 | 5 | 0.8 | 1.2 | 14.3 | 292 |

5x0.75 | 5 | 0.6 | 0.9 | 9.3 | 106 |

5x1.0 | 5 | 0.6 | 0.9 | 9.8 | 123 |

5x1.5 | 5 | 0.7 | 1.1 | 11.6 | 176 |

5x2.5 | 5 | 0.8 | 1.2 | 13.9 | 262 |

5x4.0 | 5 | 0.8 | 1.4 | 16.1 | 369 |

ELECTRICAL PROPERTIES

Current-Carrying Capacities (Amp) according to BS7671:2008 table 4F3A

Conductor cross-sectional area | Single-phase a.c. | Three-phase a.c. |

|---|---|---|

mm² | A | A |

0.75 | 6 | 6 |

1.0 | 10 | 10 |

1.5 | 16 | 16 |

2.5 | 25 | 20 |

4.0 | 32 | 25 |

Voltage Drop (Per Amp Per Meter) according to BS7671:2008 table 4F3B

Conductor cross-sectional area | d.c. or single-phase a.c. | Three-phase a.c. |

|---|---|---|

mm² | mV/A/m | mV/A/m |

0.75 | 62 | 54 |

1.0 | 46 | 40 |

1.5 | 32 | 27 |

2.5 | 19 | 16 |

4.0 | 12 | 10 |

What Are 300/500V PVC Insulated Power Cables?

The designation "300/500V" refers to the voltage rating of these cables, indicating they are designed for systems with a nominal voltage up to 300V between phase and earth, and 500V between phases. These cables, built to the BS EN 50525-2-11 standard (formerly BS 6500), are flexible, multi-core cables with polyvinyl chloride (PVC) insulation and sheathing. Available in configurations of 2 to 5 cores, they are tailored for low-voltage applications where flexibility, durability, and safety are paramount.

The use of PVC as both insulation and sheathing material makes these cables cost-effective, durable, and resistant to environmental stressors. Their compliance with rigorous standards ensures they meet strict safety and performance criteria, making them suitable for critical applications in industries ranging from transportation to healthcare.

Applications: Powering Critical Infrastructure

The versatility of 300/500V PVC insulated, PVC sheathed power cables makes them a go-to choice for a wide range of applications. They are commonly found in:

Power Stations: These cables distribute power within control rooms and auxiliary systems, ensuring reliable operation of critical equipment.

Mass Transit Systems: Underground passenger systems rely on these cables for lighting, signaling, and control systems, where flexibility and fire safety are crucial.

Airports: From runway lighting to terminal power distribution, these cables support the complex electrical needs of aviation infrastructure.

Petrochemical Plants: In environments with potential exposure to chemicals, the cables’ optional hydrocarbon resistance ensures longevity and safety.

Hospitals and Hotels: These cables power essential systems like lighting, HVAC, and medical equipment, where reliability is non-negotiable.

High-Rise Buildings: Their flexibility and fire-retardant properties make them ideal for complex wiring in tall structures.

Standards and Fire Performance

Compliance with BS EN 50525-2-11 ensures that these cables meet stringent European standards for low-voltage flexible cables. This standard, which replaced BS 6500, outlines requirements for construction, electrical performance, and safety. A key aspect of their design is fire performance, particularly flame retardance, tested under EN 60332-1-2 (Single Vertical Wire Test). This ensures that the cables resist flame propagation, a critical feature in environments where fire safety is paramount.

For applications requiring enhanced fire performance, options like Low Smoke PVC (LSPVC) can be incorporated, reducing smoke emission in case of fire. Compliance with additional standards like IEC 60332-3, UL 1581, or UL 1666 depends on the specific PVC compound used and the overall cable design, making these cables adaptable to diverse safety requirements.

Advantages of PVC Insulated, PVC Sheathed Cables

These cables offer several advantages that make them a preferred choice:

Cost-Effectiveness: PVC is an economical material, making these cables affordable without compromising quality.

Flexibility: Class 5 conductors provide excellent flexibility, ideal for complex installations.

Durability: The PVC sheath protects against mechanical damage, moisture, and chemical exposure.

Fire Safety: Flame-retardant properties and optional LSPVC enhance safety in fire-prone environments.

Customizability: Options like UV resistance and anti-rodent properties allow tailored solutions for specific needs.

Challenges and Considerations

While these cables are highly versatile, there are some considerations:

Temperature Limitations: The maximum operating temperature of 70°C may not suit extreme high-temperature environments.

Environmental Impact: PVC production and disposal have environmental implications, though recyclable PVC compounds are emerging.

Specialized Requirements: For highly corrosive environments, additional protective coatings may be needed.

Conclusion

The 300/500V PVC insulated, PVC sheathed power cables to BS EN 50525 (2-5 cores) are a cornerstone of modern electrical infrastructure. Their robust construction, compliance with stringent standards, and adaptability to diverse applications make them indispensable in powering critical systems worldwide. From their flexible copper conductors to their flame-retardant PVC sheathing, every aspect of these cables is designed for safety, efficiency, and durability. As technology evolves, these cables will continue to play a vital role in supporting the world’s growing electrical demands, proving that even the smallest components can have a monumental impact.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430