Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V PVC Insulated, PVC Sheathed, Twin & Earth Cables (2-3 Cores)

300/500V PVC Insulated, PVC Sheathed, Twin & Earth Cables (2-3 Cores)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

STANDARDS

Basic design to BS 6004:2012

FIRE PERFORMANCE

Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2 |

VOLTAGE RATING

300/500V

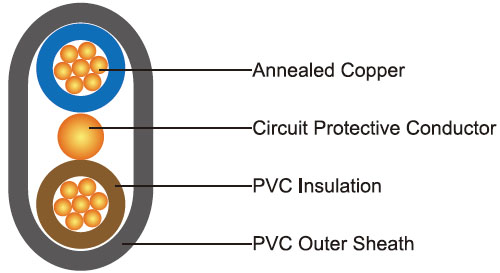

CABLE CONSTRUCTION

Conductor | Annealed copper conductor,class 1 (1.0mm² to 2.5mm²) or class 2 (4mm² to 35mm²) according to BS EN 60228. |

Insulation | PVC Type TI 1 according to BS EN 50363-3. |

Circuit Protective Conductor (CPC) | Annealed plain copper (class 1 or 2) |

Position of CPC | Centrally placed between cores in same plane (twin); centrally placed between black and grey cores in same plane(3-core). |

Outer Sheath | PVC Type 6 according to BS 7655-4.2. |

Outer Sheath Option | UV resistance,hydrocarbon resistance,oil resistance,anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1,IEC 60332-3,UL 1581,UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

COLOUR CODE

Insulation Colour :

Twin : brown and blue, alternatively, for 2 x 1.0 and 2 x 1.5 cables, brown and brown;

3-core : brown, black (centre core), and grey

Sheath Colour : Grey, other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C |

Maximum short circuit temperature (5 Seconds) | 160°C |

Minimum bending radius | 6 x Overall Diameter |

CONSTRUCTION PARAMETERS

Conductor | FGD200-E 05VV-U/R | ||||||

|---|---|---|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | Nominal Insulation Thickness | Cross-Section Area of CPC | Class of CPC | Nominal Sheath Thickness | Maximum Overall Diameter | Approx. Weight |

No.xmm² |

| mm | mm² |

| mm | mm | kg/km |

2x1.0 | 1 | 0.6 | 1.0 | 1 | 0.9 | 4.8x8.7 | 68 |

2x1.5 | 1 | 0.7 | 1.0 | 1 | 0.9 | 5.3x9.7 | 85 |

2x2.5 | 1 | 0.8 | 1.5 | 1 | 1.0 | 6.2x11.7 | 120 |

2x4.0 | 2 | 0.8 | 1.5 | 1 | 1.0 | 6.9x13.1 | 175 |

2x6.0 | 2 | 0.8 | 2.5 | 1 | 1.1 | 7.8x15.0 | 240 |

2x10 | 2 | 1.0 | 4.0 | 2 | 1.2 | 9.5x18.9 | 390 |

2x16 | 2 | 1.0 | 6.0 | 2 | 1.3 | 10.8x21.9 | 560 |

3x1.0 | 1 | 0.6 | 1.0 | 1 | 0.9 | 4.8x11.4 | 91 |

3x1.5 | 1 | 0.7 | 1.0 | 1 | 0.9 | 5.3x12.9 | 115 |

3x2.5 | 1 | 0.8 | 1.5 | 1 | 1.0 | 6.2x15.3 | 170 |

3x4.0 | 2 | 0.8 | 1.5 | 1 | 1.1 | 7.1x17.9 | 250 |

3x6.0 | 2 | 0.8 | 2.5 | 1 | 1.1 | 7.8x20.2 | 340 |

3x10 | 2 | 1.0 | 4.0 | 2 | 1.2 | 9.5x25.7 | 540 |

3x16 | 2 | 1.0 | 6.0 | 2 | 1.3 | 10.8x29.7 | 790 |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 70°C |

Ambient Temperature | 30°C |

Current-Carrying Capacities (Amp) and Voltage Drop (Per Amp Per Meter) according to BS7671:2008 table 4D5

Conductor cross-sectional area | Reference Method 100# (above a plasterboard ceiling covered by thermal insulation not exceeding 100 mm in thickness) | Reference Method 101# (above a plasterboard ceiling covered by thermal insulation exceeding 100 mm in thickness) | Reference Method 102# (in a stud wall with thermal insulation with cable touching the inner wall surface) | Reference Method 103# (in a stud wall with thermal insulation with cable not touching the inner wall surface) | Reference Method C* (clipped direct) | Reference Method A* (enclosed in conduit in an insulated wall) | Voltage Drop (per ampere per meter) |

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

mm² | A | A | A | A | A | A | mV/A/m |

1.0 | 13 | 10.5 | 13 | 8.0 | 16 | 11.5 | 44 |

1.5 | 16 | 13 | 16 | 10 | 20 | 14.5 | 29 |

2.5 | 21 | 17 | 21 | 13.5 | 27 | 20 | 18 |

4.0 | 27 | 22 | 27 | 17.5 | 37 | 26 | 11 |

6.0 | 34 | 27 | 35 | 23.5 | 47 | 32 | 7.3 |

10 | 45 | 36 | 47 | 32 | 64 | 44 | 4.4 |

16 | 57 | 46 | 63 | 42.5 | 85 | 57 | 2.8 |

A* For full installation method refer to Table 4A2 (BS 7671-2008) Installation Method 2 but for flat twin and earth cable

C* For full installation method refer to Table 4A2 (BS 7671-2008) Installation Method 20 but for flat twin and earth cable

100# For full installation method refer to Table 4A2 (BS 7671-2008) Installation Method 100

102# For full installation method refer to Table 4A2 (BS 7671-2008) Installation Method 102

103# For full installation method refer to Table 4A2 (BS 7671-2008) Installation Method 103

Wherever practicable, a cable is to be fixed in a position such that it will not be covered with thermal insulation.

Regulation 523.7, BS 5803-5 Appendix C: Avoidance of overheating of electric cables, Building Regulations Approved document B and Thermal insulation: avoiding risks, BR 262, BRE, 2001 refer.

What Are 300/500V PVC Insulated, PVC Sheathed, Twin & Earth Cables?

Twin & earth cables are named for their configuration: they typically consist of two or three insulated conductors (cores) alongside an uninsulated circuit protective conductor (CPC), commonly known as the earth wire. The 300/500V rating indicates the cable’s voltage capacity, making it suitable for low to medium voltage applications. The PVC insulation and PVC sheath provide durability, flexibility, and protection against environmental factors, ensuring the cable performs reliably in diverse conditions.

These cables are primarily used in fixed installations, such as wiring within walls, ceilings, or conduits. Their flat, compact design makes them easy to install in tight spaces, while their robust construction ensures compliance with safety standards like BS EN 60332-1-2 for flame retardance. Whether in a hospital, airport, or petrochemical plant, these cables deliver consistent performance under demanding conditions.

Key Applications of Twin & Earth Cables

The versatility of 300/500V PVC insulated, PVC sheathed, twin & earth cables makes them suitable for a wide range of applications. Their TUV-approved design ensures reliability in critical infrastructure, including:

Power Stations: These cables handle the high electrical demands of power generation and distribution systems.

Mass Transit Systems: Underground passenger systems rely on these cables for lighting, signaling, and power distribution.

Airports: Twin & earth cables are used in terminal buildings, runways, and control towers for safe and efficient power delivery.

Petrochemical Plants: Their optional resistance to hydrocarbons and oils makes them ideal for harsh industrial environments.

Hospitals: The cables’ flame-retardant properties and compliance with safety standards ensure reliable power for critical medical equipment.

Hotels and High-Rise Buildings: Their compact design and flexibility make them perfect for complex wiring systems in multi-story structures.

Fire Performance and Safety Standards

Safety is a top priority in electrical installations, and twin & earth cables are designed to meet rigorous fire performance standards. Their flame retardance is tested to EN 60332-1-2, ensuring they resist flame propagation in a single vertical wire test. For applications requiring enhanced fire safety, the cables can comply with standards like IEC 60332-3, UL 1581, or UL 1666, depending on the PVC compound used.

Additionally, compliance with BS 7671:2008 and BS 5803-5 ensures that the cables are installed in ways that avoid overheating, particularly in environments with thermal insulation. Regulations like 523.7 and Approved Document B emphasize the importance of positioning cables to avoid coverage by thermal insulation, further enhancing safety.

Optional Enhancements for Specialized Applications

While the standard twin & earth cable is highly versatile, optional enhancements can tailor its performance to specific needs:

UV Resistance: Ideal for outdoor or exposed installations.

Hydrocarbon and Oil Resistance: Suitable for petrochemical or industrial environments.

Anti-Rodent and Anti-Termite Properties: Protects cables in areas prone to pest damage.

Low Smoke PVC (LSPVC): Reduces smoke and toxic gas emissions in fire-prone areas.

Why Choose 300/500V PVC Insulated, PVC Sheathed, Twin & Earth Cables?

The popularity of these cables stems from their balance of performance, safety, and versatility. Key advantages include:

Compliance with Standards: Meeting BS 6004:2012, BS EN 60228, and fire performance standards ensures reliability and safety.

Flexible Design: The flat, compact design simplifies installation in tight spaces.

Customizable Options: Enhancements like UV resistance or LSPVC cater to specialized needs.

Wide Application Range: From domestic wiring to industrial power systems, these cables are a universal solution.

300/500V PVC insulated, PVC sheathed, twin & earth cables are a cornerstone of modern electrical installations. Their robust construction, compliance with stringent safety standards, and adaptability to diverse environments make them an ideal choice for a wide range of applications. From their annealed copper conductors to their flame-retardant PVC sheaths, every component is designed to deliver performance, safety, and durability.

As electrical systems continue to evolve, twin & earth cables will remain a trusted solution for powering the infrastructure of tomorrow. Whether in a high-rise building, a hospital, or a petrochemical plant, these cables provide the reliability and flexibility needed to keep the world connected.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430