Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V SR Insulated, LSZH Sheathed, Screened Power Cables to BS 7629-1 (2-4 Cores & Multcore)

APPLICATION

The cables are primarily intended for use in the following applications:

BS 5266-1 for emergency lighting of premises.

BS 5839-1 for fire detection and fire alarm systems in and around building.

BS 5839-8 for voice alarm systems.

BS 5839-9 for emergency voice communication systems.

STANDARDS

Basic design to BS 7629-1:2015

FIRE PERFORMANCE

Circuit Integrity | BS 6387; BS EN50200 |

Flame Retardance (single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No corrosive Gas emission | IEC 60754-2; EN 50267-2-2 |

Minimum smoke emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

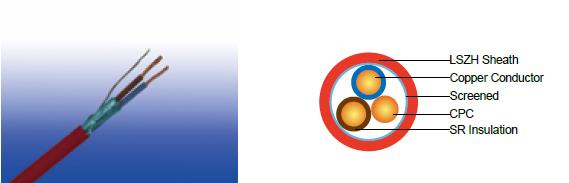

CABLE CONSTRUCTION

Conductor : Copper conductor according to BS EN 60228 class 1/2.

Insulation : Fire resistant special ceramized silicone rubber compound type EI 2 as per BS EN 50363-1.

Screened : One or more metallic or laminated metallic tape(s) shall be applied, either longitudinally or helically or a combination of both, with the metallic element in contact with the uninsulated circuit protective conductor or drain wire.

Circuit Protective Conductor : Uninsulated tinned copper conductor of the same section and class as the insulated conductors in the two,three and four cores cables.

Sheath : Extruded LSZH type LTS 3 according to BS 7655-6.1.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

Number of cores | Core colours or numbering |

2 cores+uninsulated circuit protective conductor | Brown, Blue or Brown, Brown |

3 cores+uninsulated circuit protective conductor | Brown, Black, Grey |

4 cores+uninsulated circuit protective conductor | Brown, Blue, Black, Grey |

7, 12 and19 cores+uninsulated drain wire | Numbers 1, 2, 3, 4, 5, 6, 7 and upwards or, for identification by colour, an identical colour(excluding brown and black),except for two adjacent cores in each layer distinctively coloured brown and black. |

Sheath Colour : Colours upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 60°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 6 x Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX200 05SOZ1-U/R PH30/PH60 | |||||

|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | CPC Nominal Cross-sectional Area | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

no.×mm² |

| mm | mm² | mm | mm | kg/km |

2 cores | ||||||

1/2 | 0.6 | 1.0 | 0.9 | 8.0 | 78 | |

1/2 | 0.7 | 1.5 | 0.9 | 8.5 | 103 | |

1/2 | 0.8 | 2.5 | 1.0 | 10.5 | 150 | |

1/2 | 0.8 | 4.0 | 1.1 | 12.5 | 212 | |

3 cores | ||||||

1/2 | 0.7 | 1.5 | 0.9 | 9.5 | 130 | |

1/2 | 0.8 | 2.5 | 1.0 | 11.5 | 191 | |

1/2 | 0.8 | 4.0 | 1.1 | 13.5 | 273 | |

4 cores | ||||||

1/2 | 0.7 | 1.5 | 1.0 | 10.5 | 165 | |

1/2 | 0.8 | 2.5 | 1.1 | 12.0 | 242 | |

1/2 | 0.8 | 4.0 | 1.2 | 15.0 | 344 | |

7 cores | ||||||

1/2 | 0.7 | 0.5 | 1.1 | 12.5 | 257 | |

1/2 | 0.8 | 0.5 | 1.2 | 15.0 | 568 | |

12 cores | ||||||

1/2 | 0.7 | 0.5 | 1.2 | 16.0 | 414 | |

1/2 | 0.8 | 0.5 | 1.4 | 20.0 | 886 | |

19 cores | ||||||

1/2 | 0.7 | 0.5 | 1.3 | 19.0 | 617 | |

ELECTRICAL PROPERTIES

Conductor operating temperature : 70°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4D2A

Conductor cross-sectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc) | Ref. Method B (enclosed in conduit on a wall or in trunking etc) | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 four-core cable*, three-phase a.c. | 1 two-core cable*, singlephase a.c. or d.c. | 1 three-core or 1 four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 four-core cable*, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | A | A | A | A | A | A | A | A |

1.0 | 11 | 10 | 13 | 11.5 | 15 | 13.5 | 17 | 14.5 |

1.5 | 14 | 13 | 16.5 | 15 | 19.5 | 17.5 | 22 | 18.5 |

2.5 | 18.5 | 17.5 | 23 | 20 | 27 | 24 | 30 | 25 |

4 | 25 | 23 | 30 | 27 | 36 | 32 | 40 | 34 |

Note: *With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4D2B

Conductor cross-sectional area | Two-core cable d.c. | Two-core cable single-phase a.c. | Three- or four-core cable, three-phase a.c. |

|---|---|---|---|

1 | 2 | 3 | 4 |

mm² | mV/A/m | mV/A/m | mV/A/m |

1.0 | 44 | 44 | 38 |

1.5 | 29 | 29 | 25 |

2.5 | 18 | 18 | 15 |

4 | 11 | 11 | 9.5 |

Introduction

In an era where building safety is paramount, particularly in regions prone to electrical faults and fire hazards, the role of specialised cables cannot be overstated. The 300/500V SR Insulated, LSZH Sheathed, Screened Power Cables, designed to BS 7629-1 standards, represent a critical advancement in fire-resistant technology. These cables, often referred to as fire performance or fire survival cables, are engineered to maintain circuit integrity during fires, ensuring that essential systems like emergency lighting and fire alarms remain operational. This is especially relevant in South Africa, where urbanisation, load-shedding, and recent fire incidents have heightened the focus on robust fire safety infrastructure.

South Africa's building regulations, governed by the South African National Standards (SANS), align closely with international benchmarks such as British Standards (BS). For instance, SANS 10139 outlines requirements for fire detection and alarm systems, emphasising the need for cables that can withstand extreme conditions. The BS 7629-1 standard specifically addresses multicore cables with silicone rubber (SR) insulation and low smoke zero halogen (LSZH) sheathing, making them ideal for screened power applications in 2-4 core and multicore configurations. These cables are not just wires; they are lifelines in emergencies, reducing smoke emission and halogen gases that could exacerbate fire spread or impair evacuation.

Fire Performance and Testing

The defining feature of these cables is their fire performance, scientifically validated through stringent tests. Circuit integrity is proven under BS 6387, enduring 950°C flame for 180 minutes (category C), water spray (W), and mechanical impact (Z). BS EN 50200 adds PH classification: PH30/PH60 indicate 30/60 minutes of resistance at 830°C with shock.

Flame retardance prevents self-ignition, per IEC 60332-1-2, where a vertical cable withstands a 1 kW flame without spreading beyond 50-540 mm. For bundles, IEC 60332-3-24 limits char length to 2.5 m. Halogen-free testing (IEC 60754-1) ensures <0.5% halogen content, while acidity (IEC 60754-2) maintains conductivity <10 µS/mm, minimising corrosion to equipment.

Smoke emission, critical for visibility during evacuation, is tested via IEC 61034-2, achieving >60% light transmittance in a 3m cube. These metrics translate to real-world benefits: in a fire, LSZH sheathing reduces smoke density by up to 80% compared to PVC, aiding escape as per South African evacuation guidelines.

In 2025 analyses, such as those from the International Fire and Safety Journal, these cables have shown superior performance in simulated building fires, maintaining power to alarms and lights. South African adaptations include integration with SANS-compliant systems, addressing local challenges like veld fires impacting urban edges.

Usage Scenarios and Applications

Primarily for emergency systems, these cables power fire alarms, voice communications, and lighting in buildings. In hospitals, they ensure uninterrupted ICU monitoring; in malls, they facilitate evacuation.

In South Africa, suppliers like WASIN SA promote them for schools and offices, compliant with SANS 10139. Options like PH30/PH60 suit varying risk levels.

South African Case Studies and Lessons Learned

Recent South African initiatives highlight these cables' value. In 2024, following Johannesburg's commercial fires documented by FPASA, a retrofit project in an office block used BS 7629-1-compliant LSZH cables for alarm upgrades, reducing potential smoke hazards. ERF Group's installations in shopping centres, as per their 2025 reports, integrated fire-resistant cables in detection systems, maintaining functionality during simulated tests amid load-shedding.

A 2025 case from Cape Town's nonCrete partners involved fire-resistant materials in housing, incorporating LSZH cables to enhance safety post-wildfire threats. Lessons from Table Mountain's February 2025 blaze emphasised early detection, with cables ensuring system resilience. The Fire Institute of South Africa's successes in business prevention underscore proactive use, cutting incident rates by 60%.

These cases reveal substandard cables' risks, as warned in 2025 by local manufacturers, advocating BS/SANS compliance for future projects.

The 300/500V SR Insulated LSZH Sheathed Screened Power Cables to BS 7629-1 exemplify engineering excellence, blending fire resistance with electrical reliability. In South Africa, their adoption amid evolving regulations promises safer buildings, drawing from recent case studies to inform best practices.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430