Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-3 Cores)

A Comprehensive Guide to 300/500V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-3 Cores)

300/500V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-3 Cores)

FTX200 05RZ1-U/R (CU/XLPE/LSZH 300/500V Class 1/2)

BS Code : 6242B/6243

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS 7211:2012

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

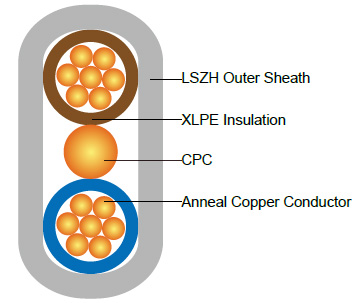

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, solid or stranded according to BS EN 60228 class 1 or class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 can be offered as option.

CPC (Circuit Protective Conductor) : Uninsulated copper conductor.

Outer Sheath : Extruded LSZH type LTS 2 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

Twin : Brown and blue or, for 2x1.0 and 2x1.5 cables, brown and brown.

Three cores : Brown, black (centre core) and grey.

Position of CPC :

Twin : Centrally placed between cores in same plane.

Three cores : Centrally placed between black and grey cores in same plane.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX200 05RZ1-U/R | |||||||

|---|---|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Cross-sectional Area of CPC | Class of CPC | Nominal Sheath Thickness | Min. overall Dimensions | Max. overall Dimensions | Approx. Weight |

No.×mm² |

| mm | mm² |

| mm | mm | mm | kg/km |

2×1.0 | 1 | 0.7 | 1.0 | 1 | 0.9 | 4.1×7.6 | 5.0×9.2 | 68 |

2×1.5 | 1 | 0.7 | 1.0 | 1 | 0.9 | 4.4×8.1 | 5.3×9.7 | 85 |

2×2.5 | 1 | 0.7 | 1.5 | 1 | 1.0 | 4.9×9.3 | 6.0×11.2 | 120 |

3×1.0 | 1 | 0.7 | 1.0 | 1 | 0.9 | 4.1×10.0 | 5.0×12.1 | 91 |

3×1.5 | 1 | 0.7 | 1.0 | 1 | 0.9 | 4.4×10.7 | 5.3×12.9 | 115 |

3×2.5 | 1 | 0.7 | 1.5 | 1 | 1.0 | 4.9×12.0 | 6.0×14.6 | 170 |

2×1.0 | 2 | 0.7 | 1.0 | 1 | 0.9 | 4.2×7.8 | 5.1×9.4 | 73 |

2×1.5 | 2 | 0.7 | 1.0 | 1 | 0.9 | 4.5×8.3 | 5.4×10.0 | 90 |

2×2.5 | 2 | 0.7 | 1.5 | 1 | 1.0 | 5.0×9.5 | 6.1×11.4 | 125 |

2×4 | 2 | 0.7 | 1.5 | 1 | 1.0 | 5.5×10.4 | 6.7×12.6 | 175 |

2×6 | 2 | 0.7 | 2.5 | 1 | 1.1 | 6.2×12.0 | 7.5×14.6 | 240 |

2×10 | 2 | 0.7 | 4.0 | 2 | 1.2 | 7.3×14.5 | 8.8×17.5 | 390 |

2×16 | 2 | 0.7 | 6.0 | 2 | 1.3 | 8.4×17.0 | 10.1×20.5 | 560 |

3×4 | 2 | 0.7 | 1.5 | 1 | 1.0 | 5.5×14.0 | 6.7×16.9 | 196 |

3×6 | 2 | 0.7 | 2.5 | 1 | 1.1 | 6.2×16.2 | 7.5×19.5 | 291 |

3×10 | 2 | 0.7 | 4.0 | 2 | 1.2 | 7.3×19.5 | 8.8×23.6 | 440 |

3×16 | 2 | 0.7 | 6.0 | 2 | 1.3 | 8.4×22.8 | 10.1×27.6 | 670 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

Conductor Cross-sectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | Ref. Method E (free air or on a perforated cable tray etc. horizontal or vertical) | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core cable*, single-phase a.c. or d.c. | 1 three-or four core cable*, three- phase a.c. | 1 two-core cable*, single- phase a.c. or d.c. | 1 three-or four core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-or four core cable*, three- phase a.c. | 1 two-core cable*, single- phase a.c. or d.c. | 1 three-or four core cable*, three- phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | A | A | A | A | A | A | A | A |

1.0 | 14.5 | 13 | 17 | 15 | 19 | 17 | 21 | 18 |

1.5 | 18.5 | 16.5 | 22 | 19.5 | 24 | 22 | 26 | 23 |

2.5 | 25 | 22 | 30 | 26 | 33 | 30 | 36 | 32 |

4 | 33 | 30 | 40 | 35 | 45 | 40 | 49 | 42 |

6 | 42 | 38 | 51 | 44 | 58 | 52 | 63 | 54 |

10 | 57 | 51 | 69 | 60 | 80 | 71 | 86 | 75 |

16 | 76 | 68 | 91 | 80 | 107 | 96 | 115 | 100 |

Note: With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

Conductor cross-sectional area | Two-core cable, d.c. | Two-core cable, single-phase a.c. | Three or four core cable, three-phase a.c. |

|---|---|---|---|

1 | 2 | 3 | 4 |

mm² | mV/A/m | mV/A/m | mV/A/m |

1.0 | 46 | 46 | 40 |

1.5 | 31 | 31 | 27 |

2.5 | 19 | 19 | 16 |

4 | 12 | 12 | 10 |

6 | 7.9 | 7.9 | 6.8 |

10 | 4.7 | 4.7 | 4.0 |

16 | 2.9 | 2.9 | 2.5 |

What Are XLPE Insulated, LSZH Sheathed Power Cables?

Cable Construction and Standards

The 300/500V XLPE insulated, LSZH sheathed power cables are designed to deliver power safely and efficiently in low-voltage systems. Compliant with BS 7211:2012, these cables are available in 2-core and 3-core configurations, identified by codes 6242B (twin) and 6243 (three-core). Their construction includes:

Conductor: Made from annealed copper, either solid (Class 1) or stranded (Class 2) per BS EN 60228, ensuring excellent conductivity and flexibility.

Insulation: XLPE (type GP8) as per BS 7655-1.3, or optionally crosslinked polyolefin (type EI 5) per EN 50363-5, offering superior thermal resistance up to 90°C during operation and 250°C during short circuits (up to 5 seconds).

Circuit Protective Conductor (CPC): An uninsulated copper conductor, centrally placed between cores, enhancing safety by providing a grounding path.

Outer Sheath: LSZH (type LTS 2) per BS 7655-6.1, which minimizes smoke and toxic gas emissions during fires. Optional features include UV resistance, hydrocarbon resistance, oil resistance, and anti-rodent/anti-termite properties.

The cables’ voltage rating of 300/500V makes them suitable for low-voltage applications, balancing safety and performance in environments requiring reliable power distribution.

Fire Performance: A Safety-First Approach

One of the standout features of these cables is their exceptional fire performance, making them ideal for enclosed or high-traffic areas. Key fire safety characteristics include:

Flame Retardance: Compliant with IEC 60332-1-2 and EN 60332-1-2, ensuring the cable resists flame spread in a single vertical wire test.

Reduced Fire Propagation: Meets IEC 60332-3-24 and EN 60332-3-24, limiting fire spread in bundled cable installations.

Halogen-Free: Per IEC 60754-1 and EN 50267-2-1, the cables emit no halogen gases, reducing toxicity risks.

Low Corrosive Gas Emission: Compliant with IEC 60754-2 and EN 50267-2-2, minimizing damage to equipment and health risks.

Minimum Smoke Emission: Adheres to IEC 61034-2 and EN 61034-2, ensuring better visibility during fire evacuations.

These properties make the cables a go-to solution for safety-critical applications, such as hospitals and underground transit systems, where smoke and toxic fumes could pose significant risks.

Applications in South Africa’s Mining and Heavy Industry Sectors

South Africa’s economy heavily relies on its mining and heavy industry sectors, where reliable and safe power distribution is paramount. The 300/500V XLPE insulated, LSZH sheathed power cables are particularly well-suited for these environments due to their fire safety, durability, and adaptability.

Case Study: Enhancing Safety in South African Gold Mines

In South Africa’s gold mining industry, underground operations face unique challenges, including confined spaces, high temperatures, and the risk of fires. A prominent gold mine in the Witwatersrand Basin recently upgraded its electrical infrastructure to comply with stricter safety regulations. The mine adopted FTX200 05RZ1-U/R cables for their underground power distribution systems. The LSZH sheathing was critical in reducing smoke and toxic gas emissions, ensuring safer evacuation routes during emergencies. Additionally, the cables’ UV and oil resistance options protected against harsh environmental conditions, such as exposure to mining chemicals and sunlight at surface installations.

The use of 3×6 mm² cables (current-carrying capacity of 52 A in clipped direct installations) ensured reliable power delivery to heavy machinery, while the 90°C operating temperature accommodated the high ambient temperatures in deep-level mining. This upgrade not only improved safety but also reduced maintenance costs by 15%, as reported by the mine’s engineering team in 2024.

Why Choose XLPE Insulated, LSZH Sheathed Cables?

Advantages Over Traditional Cables

Compared to traditional PVC-insulated cables, XLPE insulated, LSZH sheathed cables offer several benefits:

Enhanced Fire Safety: The LSZH sheath significantly reduces smoke and toxic gas emissions, critical for public safety in confined spaces.

Higher Temperature Tolerance: XLPE insulation supports 90°C operation, compared to 70°C for PVC, allowing for higher current capacities.

Durability: Optional features like UV and hydrocarbon resistance make these cables suitable for extreme environments.

Compliance: Adherence to BS 7211:2012 and international fire safety standards ensures global applicability.

The 300/500V XLPE insulated, LSZH sheathed power cables are a cornerstone of modern electrical systems, offering unmatched safety, reliability, and versatility. Their compliance with BS 7211:2012, coupled with superior fire performance and durability, makes them indispensable in high-risk environments like South Africa’s mining and petrochemical industries. By addressing safety concerns and supporting ESG goals, these cables are paving the way for safer and more sustainable power distribution. Whether in a gold mine in the Witwatersrand or a petrochemical plant in Sasolburg, these cables deliver power where it’s needed most, without compromising on safety or efficiency.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430