Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (Single Core)

300/500V XLPE Insulated, LSZH Sheathed Power Cables, Compliant with BS 7211 Standards: Standing Out for Their Robust Design and Exceptional Safety Features

300/500V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (Single Core)

FTX300 05RZ1-U (CU/XLPE/LSZH 300/500V Class 1)

BS Code : 6241B

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS 7211:2012

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

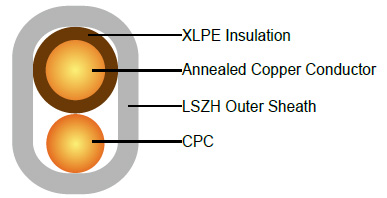

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, solid according to BS EN 60228 class 1.

Insulation : XLPE type GP8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 can be offered as option.

CPC (Circuit Protective Conductor) : Uninsulated copper conductor.

Outer Sheath : Extruded LSZH type LTS 2 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 4 x Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX300 05RZ1-U | |||||||

|---|---|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Cross- sectional Area of CPC | Class of CPC | Nominal Insulation Thickness | Min. overall Dimensions | Max. overall Dimensions | Approx. Weight |

No.×mm² |

| mm | mm² |

| mm | mm | mm | kg/km |

1×1.0 | 1 | 0.70 | 1.0 | 1 | 0.9 | 4.1x5.2 | 5.0x6.3 | 45 |

1×1.5 | 1 | 0.70 | 1.0 | 1 | 0.9 | 4.4x5.4 | 5.3x6.6 | 55 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E1A

Conductor cross- ectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | |||

|---|---|---|---|---|---|---|

2 cables, single-phase a.c. or d.c. | 3 or 4 cables, three-phase a.c. | 2 cables, single-phase a.c. or d.c | 3 or 4 cables, three-phase a.c. | 2 cables, single- phase a.c. or d.c. flat and touching | 3 or 4 cables, three-phase a.c. flat and touching or trefoil | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm² | A | A | A | A | A | A |

1.0 | 14 | 13 | 17 | 15 | 19 | 17.5 |

1.5 | 19 | 17 | 23 | 20 | 25 | 23 |

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E1B

Conductor cross- sectional area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | |||||

|---|---|---|---|---|---|---|---|---|

Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | |||||

Cables touching, Trefoil | Cables touching, flat | Cables spaced*, flat | ||||||

Cables touching | Cables spaced* | |||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

1.0 | 46 | 46 | 46 | 46 | 40 | 40 | 40 | 40 |

1.5 | 31 | 31 | 31 | 31 | 27 | 27 | 27 | 27 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

What Are XLPE Insulated, LSZH Sheathed Power Cables?

At their core, 300/500V XLPE insulated, LSZH sheathed power cables are designed to transmit electrical power safely and efficiently in environments where safety is paramount. The acronym XLPE stands for Cross-Linked Polyethylene, a high-performance insulation material known for its excellent thermal and electrical properties. LSZH, or Low Smoke Zero Halogen, refers to the cable’s outer sheath, which emits minimal smoke and no toxic halogen gases when exposed to fire. This combination makes these cables ideal for enclosed or densely populated spaces where fire safety is a critical concern.

The BS 7211 standard, established by the British Standards Institution, outlines the specifications for these cables, ensuring they meet stringent requirements for performance, safety, and reliability. The FTX300 05RZ1-U designation indicates a single-core cable with a solid annealed copper conductor, XLPE insulation, and an LSZH sheath, rated for voltages up to 300/500V.

The Importance of Fire Safety in Cable Design

Fire safety is a cornerstone of modern electrical engineering, particularly in environments like airports, hospitals, and underground transit systems. Traditional cables with PVC (Polyvinyl Chloride) sheaths can release toxic fumes and dense smoke when burned, posing significant risks to human life and complicating evacuation efforts. In contrast, LSZH sheathed cables are engineered to minimize these dangers. According to standards like IEC 60754-1 and EN 50267-2-1, these cables are halogen-free, meaning they do not emit corrosive gases during combustion. Additionally, IEC 61034-2 and EN 61034-2 ensure minimal smoke emission, improving visibility in fire scenarios.

The flame retardance of these cables, tested under IEC 60332-1-2 and EN 60332-1-2, ensures that a single cable will not propagate fire easily. For bundled cables, the reduced fire propagation properties, as per IEC 60332-3-24 and EN 60332-3-24, further enhance safety by limiting the spread of flames. These characteristics make XLPE insulated, LSZH sheathed cables a preferred choice in high-stakes environments where fire hazards must be meticulously managed.

Applications: Where These Cables Shine

The versatility of 300/500V XLPE insulated, LSZH sheathed power cables makes them indispensable in a range of high-demand environments:

Power Stations: Their high thermal tolerance and fire safety features ensure reliable power distribution in high-risk areas.

Mass Transit Systems: Underground passenger systems benefit from the cables’ low smoke and zero halogen properties, enhancing passenger safety during emergencies.

Airports and Petrochemical Plants: The optional resistance to hydrocarbons and UV light makes these cables suitable for harsh industrial environments.

Hospitals and High-Rise Buildings: The minimal smoke emission and halogen-free design reduce risks to occupants during fire incidents.

Advantages Over Traditional Cables

Compared to traditional PVC-insulated cables, XLPE insulated, LSZH sheathed cables offer several advantages:

Enhanced Fire Safety: The LSZH sheath significantly reduces smoke and toxic gas emissions, improving safety in confined spaces.

Superior Thermal Performance: XLPE insulation allows for higher operating temperatures, extending the cable’s lifespan in demanding conditions.

Environmental Friendliness: The absence of halogens aligns with environmental regulations, reducing the ecological impact of cable disposal.

Customizable Options: Features like UV resistance or anti-rodent properties allow tailored solutions for specific environments.

Conclusion

The 300/500V XLPE insulated, LSZH sheathed power cables to BS 7211 standards represent a pinnacle of modern cable technology. Their robust construction, exceptional fire safety features, and versatility make them a vital component in critical infrastructure worldwide. From power stations to hospitals, these cables ensure reliable power delivery while prioritizing human safety and environmental sustainability. As technology evolves, these cables will continue to play a crucial role in powering the future safely and efficiently.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430