Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

300/500V XLPE Insulated, LSZH Sheathed, Screened Power Cables to BS 8436 (2-4 Cores)

Exploring the Versatility of 300/500V XLPE Insulated, LSZH Sheathed, Screened Power Cables in Modern Applications

300/500V XLPE Insulated, LSZH Sheathed, Screened Power Cables to BS 8436 (2-4 Cores)

FTX200 05ROZ1-U/R/K (CU/XLPE/OSCR/LSZH 300/500V Class 1/2/5)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS 8436:2011

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

300/500V

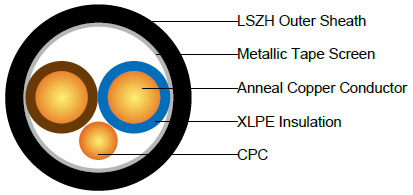

CABLE CONSTRUCTION

Conductor : Tinned annealed copper conductor, solid or stranded according to BS EN 60228 class 1, class 2 or class 5.

Insulation : Thermosetting XLPE type GP 8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 or crosslinked elastomeric GP 4/GP 6 according to BS 7655-1.2 can be offered as option.

CPC (Circuit Protective Conductor) : Uninsulated tinned annealed copper conductor conforming to BS EN 13630:2002.

Screen : One or more metallic or laminated metallic tape(s) shall be applied, either longitudinally or helically or as a combination of both, with the metallic element in contact with the uninsulated circuit protective conductor.

Outer Sheath : LSZH type LTS 3 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

2-core + uninsulated circuit protective conductor : Brown, blue or brown, brown.

3-core + uninsulated circuit protective conductor : Brown, black, grey.

4-core + uninsulated circuit protective conductor : Blue, brown, black, grey.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 70°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX200 05ROZ1-U/R/K | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

2×1.0 | 1/2/5 | 0.6 | 0.9 | 8.0 | 80 |

2×1.5 | 1/2/5 | 0.7 | 0.9 | 8.5 | 100 |

2×2.5 | 1/2/5 | 0.7 | 1.0 | 10.5 | 140 |

2×4 | 1/2/5 | 0.7 | 1.1 | 12.5 | 190 |

3×1.0 | 1/2/5 | 0.6 | 0.9 | 8.5 | 105 |

3×1.5 | 1/2/5 | 0.7 | 0.9 | 9.5 | 120 |

3×2.5 | 1/2/5 | 0.7 | 1.0 | 11.5 | 170 |

3×4 | 1/2/5 | 0.7 | 1.1 | 13.5 | 230 |

4×1.0 | 1/2/5 | 0.6 | 1.0 | 9.0 | 125 |

4×1.5 | 1/2/5 | 0.7 | 1.0 | 10.5 | 155 |

4×2.5 | 1/2/5 | 0.7 | 1.1 | 12.0 | 200 |

4×4 | 1/2/5 | 0.7 | 1.2 | 15.0 | 280 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 70°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4D2A

Conductor Cross-sectional area | Ref. Method a (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | Ref. Method E (free air or on a perforated cable tray etc. horizontal or vertical) | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 fourcore cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 fourcore cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 fourcore cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three-core or 1 fourcore cable*, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | A | A | A | A | A | A | A | A |

1.0 | 11 | 10 | 13 | 11.5 | 15 | 13.5 | 17 | 14.5 |

1.5 | 14 | 13 | 16.5 | 15 | 19.5 | 17.5 | 22 | 18.5 |

2.5 | 18.5 | 17.5 | 23 | 20 | 27 | 24 | 30 | 25 |

4 | 25 | 23 | 30 | 27 | 36 | 32 | 40 | 34 |

Note: With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4D2B

Conductor cross-sectional area | Two-core cable, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. |

|---|---|---|---|

1 | 2 | 3 | 4 |

mm² | mV/A/m | mV/A/m | mV/A/m |

1.0 | 44 | 44 | 38 |

1.5 | 29 | 29 | 25 |

2.5 | 18 | 18 | 15 |

4 | 11 | 11 | 9.5 |

What Are 300/500V XLPE Insulated, LSZH Sheathed, Screened Power Cables?

These cables are designed to deliver power safely and efficiently in environments where fire safety and minimal toxic emissions are critical. The designation “300/500V” refers to their voltage rating, making them suitable for low-voltage applications. The key components of these cables include:

Conductor: Made from tinned annealed copper, available in solid (Class 1), stranded (Class 2), or flexible (Class 5) configurations, as per BS EN 60228.

Insulation: Cross-linked polyethylene (XLPE) type GP 8, compliant with BS 7655-1.3, offers excellent thermal and electrical properties. Optional insulation materials include crosslinked polyolefin (EI 5) or elastomeric compounds (GP 4/GP 6).

Circuit Protective Conductor (CPC): An uninsulated tinned copper conductor ensures reliable grounding.

Screen: Metallic or laminated metallic tape(s), applied longitudinally or helically, provide electromagnetic interference (EMI) protection by staying in contact with the CPC.

Outer Sheath: Low smoke zero halogen (LSZH) material type LTS 3, compliant with BS 7655-6.1, minimizes smoke and toxic gas emissions during a fire. Optional features include UV resistance, hydrocarbon resistance, oil resistance, and protection against rodents and termites.

The cables are available in 2-core, 3-core, and 4-core configurations, with conductor sizes ranging from 1.0 mm² to 4.0 mm². Their insulation and sheath colors follow a standardized code for easy identification, with white being the default sheath color, though other colors can be provided upon request.

Standards and Fire Performance

The cables adhere to BS 8436:2011, a British standard that outlines requirements for low-voltage, fire-resistant cables. Their fire performance is exceptional, making them ideal for environments where human safety is a priority:

Flame Retardance: Tested to IEC 60332-1-2 and EN 60332-1-2, these cables resist flame propagation in single vertical wire or cable tests.

Halogen-Free: Compliant with IEC 60754-1 and EN 50267-2-1, they emit no halogen gases, reducing health risks in fire scenarios.

Low Corrosive Gas Emission: Per IEC 60754-2 and EN 50267-2-2, the cables produce minimal corrosive gases, protecting equipment and infrastructure.

Minimum Smoke Emission: Tested to IEC 61034-2 and EN 61034-2, they ensure better visibility in fire conditions, aiding evacuation.

Applications in South Africa’s Mining and Heavy Industries

South Africa’s mining and heavy industry sectors are pivotal to its economy, contributing significantly to GDP and employment. These industries operate in harsh environments, where safety and reliability are non-negotiable. The 300/500V XLPE insulated, LSZH sheathed, screened power cables are well-suited for such conditions due to their robust construction and fire safety features.

Case Study : Petrochemical Plant Expansion in Durban

A petrochemical plant in Durban underwent an expansion in 2025 to increase its processing capacity. The project required cables that could withstand exposure to hydrocarbons and UV radiation while maintaining fire safety. The FTX200 cables with optional hydrocarbon- and UV-resistant sheathing were installed to power new processing units. The 4-core 2.5 mm² cables provided reliable power distribution, and their LSZH sheathing ensured compliance with the plant’s stringent safety standards. The project was completed on time, with the cables contributing to a safer and more efficient facility.

The 300/500V XLPE insulated, LSZH sheathed, screened power cables to BS 8436 are a cornerstone of modern electrical infrastructure, combining safety, reliability, and performance. Their compliance with stringent fire safety standards, robust construction, and adaptability make them ideal for critical applications in power stations, transit systems, and heavy industries. In South Africa, where mining and petrochemical sectors demand high standards, these cables are proving their worth by enhancing safety and efficiency. As industries continue to prioritize sustainability and safety, the FTX200 05ROZ1-U/R/K cables will remain a vital component in powering the future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430