Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

3.6/6kV, 6/10kV, 8.7/15kV XLPE Insulated, LSOH (SHF1)Sheathed, Armoured Flame Retardant MV Power Cables (SHF1 Inner Sheath)

Application | These armoured MV cables are used on board of ships in all locations for fixed installations complying with IEC standards 60092-352. |

Standards | IEC 60092-350/351/354/359 |

Construction | |

Conductors | Class 2 stranded copper conductor. |

Conductor Screen | Semi-conducting layer (tape/compound). |

Insulation | XLPE. |

Insulation Screen | Semi-conducting layer (tape/compound). |

Metallic Screen | Copper tape |

Inner Sheath | LSOH (SHF1). |

Armour | Copper wire braid or galvanized steel wire braid. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Coloured tape shall be inserted under metallic screen. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 12×OD (single core); 9×OD (three core) |

Dimensions and Weight

3.6/6kV

Part No. | Construction No. of cores×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km | |

Inner | Outer | |||||

3.6/6KV-1C10 | 1×10 | 2.5 | 1.3 | 1.0 | 19.2 | 560 |

3.6/6KV-1C16 | 1×16 | 2.5 | 1.3 | 1.0 | 20.1 | 650 |

3.6/6KV-1C25 | 1×25 | 2.5 | 1.4 | 1.1 | 21.8 | 800 |

3.6/6KV-1C35 | 1×35 | 2.5 | 1.4 | 1.1 | 23.0 | 940 |

3.6/6KV-1C50 | 1×50 | 2.5 | 1.5 | 1.2 | 24.7 | 1120 |

3.6/6KV-1C70 | 1×70 | 2.5 | 1.6 | 1.2 | 26.7 | 1390 |

3.6/6KV-1C95 | 1×95 | 2.5 | 1.6 | 1.3 | 28.8 | 1720 |

3.6/6KV-1C120 | 1×120 | 2.5 | 1.7 | 1.3 | 30.6 | 2020 |

3.6/6KV-1C150 | 1×150 | 2.5 | 1.8 | 1.3 | 32.4 | 2350 |

3.6/6KV-1C185 | 1×185 | 2.5 | 1.8 | 1.4 | 34.4 | 2780 |

3.6/6KV-1C240 | 1×240 | 2.6 | 2.0 | 1.5 | 38.4 | 3580 |

3.6/6KV-1C300 | 1×300 | 2.8 | 2.1 | 1.6 | 41.6 | 4310 |

3.6/6KV-1C400 | 1×400 | 3.0 | 2.2 | 1.7 | 45.8 | 5440 |

3.6/6KV-1C500 | 1×500 | 3.2 | 2.4 | 1.7 | 49.3 | 6450 |

3.6/6KV-1C630 | 1×630 | 3.2 | 2.5 | 1.9 | 54.1 | 8110 |

3.6/6KV-3C10 | 3×10 | 2.5 | 1.9 | 1.4 | 36.3 | 1710 |

3.6/6KV-3C16 | 3×16 | 2.5 | 2.0 | 1.5 | 38.8 | 2030 |

3.6/6KV-3C25 | 3×25 | 2.5 | 2.1 | 1.6 | 42.0 | 2500 |

3.6/6KV-3C35 | 3×35 | 2.5 | 2.2 | 1.6 | 44.8 | 2950 |

3.6/6KV-3C50 | 3×50 | 2.5 | 2.3 | 1.7 | 48.0 | 3510 |

3.6/6KV-3C70 | 3×70 | 2.5 | 2.5 | 1.8 | 52.5 | 4420 |

3.6/6KV-3C95 | 3×95 | 2.5 | 2.6 | 1.9 | 57.0 | 5470 |

3.6/6KV-3C120 | 3×120 | 2.5 | 2.8 | 2.0 | 61.0 | 6480 |

3.6/6KV-3C150 | 3×150 | 2.5 | 2.9 | 2.1 | 64.9 | 7540 |

3.6/6KV-3C185 | 3×185 | 2.5 | 3.1 | 2.2 | 69.3 | 8940 |

3.6/6KV-3C240 | 3×240 | 2.6 | 3.3 | 2.4 | 76.4 | 11180 |

In the realm of marine engineering, the reliability and safety of electrical power distribution systems are paramount. Ships operate in harsh environments where exposure to moisture, mechanical stress, and potential fire hazards demands robust cabling solutions. Armoured medium voltage (MV) power cables, specifically those with cross-linked polyethylene (XLPE) insulation, low smoke zero halogen (LSOH) sheathing, and flame retardant properties, have emerged as critical components in modern shipboard installations. These cables, compliant with International Electrotechnical Commission (IEC) standards, ensure uninterrupted power supply while minimising risks associated with fire propagation and toxic emissions.

Standards and Compliance

The foundation of these armoured MV cables lies in their adherence to rigorous IEC standards, which govern electrical installations in marine settings. Key standards include IEC 60092-350 for general construction and test methods, IEC 60092-351 for insulating materials, IEC 60092-354 for single- and three-core power cables with extruded solid insulation for rated voltages of 6kV up to 30kV, and IEC 60092-359 for sheathing materials. Flame retardancy is ensured through IEC 60332-1 (single cable test) and IEC 60332-3-22 (bunched cables test), while low smoke and halogen-free properties comply with IEC 60754-1/2 (halogen acid gas test) and IEC 61034 (smoke density test).

These standards are particularly relevant in South African maritime regulations, which align with international norms under the South African Maritime Safety Authority (SAMSA). For instance, vessels registered in South Africa must comply with these IEC guidelines to obtain certification for operation in territorial waters. The emphasis on flame retardant, low smoke, and halogen-free characteristics addresses the unique challenges of confined ship spaces, where fire can spread rapidly and smoke can impair evacuation efforts. By incorporating these standards, the cables not only meet global benchmarks but also contribute to safer shipping practices, reducing the environmental and health impacts of potential incidents.

Characteristics of 3.6/6kV Rated Cables

The 3.6/6kV rated cables are optimised for lower medium voltage applications, such as auxiliary power systems on smaller vessels or specific deck equipment. Single-core variants range from 1×10mm² to 1×630mm², with nominal insulation thickness of 2.5mm to 3.2mm. For example, the 3.6/6KV-1C10 model features a 2.5mm insulation, 1.3mm inner sheath, 1.0mm outer sheath, resulting in a 19.2mm overall diameter and 560kg/km weight. As cross-sections increase, dimensions and weights scale accordingly; the 1×630mm² version reaches 54.1mm diameter and 8110kg/km, reflecting higher current-carrying capacity.

Three-core configurations, from 3×10mm² to 3×240mm², exhibit larger diameters due to bundled cores. The 3.6/6KV-3C10 has a 36.3mm diameter and 1710kg/km weight, escalating to 76.4mm and 11180kg/km for the 3×240mm². Nominal sheath thicknesses adjust for protection: inner sheaths from 1.9mm to 3.3mm, outer from 1.4mm to 2.4mm.

These cables excel in flame retardant performance, with LSOH sheaths ensuring minimal smoke density and zero halogen release, critical for crew safety during fires. The armour enhances tensile strength, making them suitable for vertical runs in ship engine rooms. In terms of advantages, their lower voltage rating allows for cost-effective installations where full 15kV capacity is unnecessary, yet they maintain high insulation integrity against partial discharges.

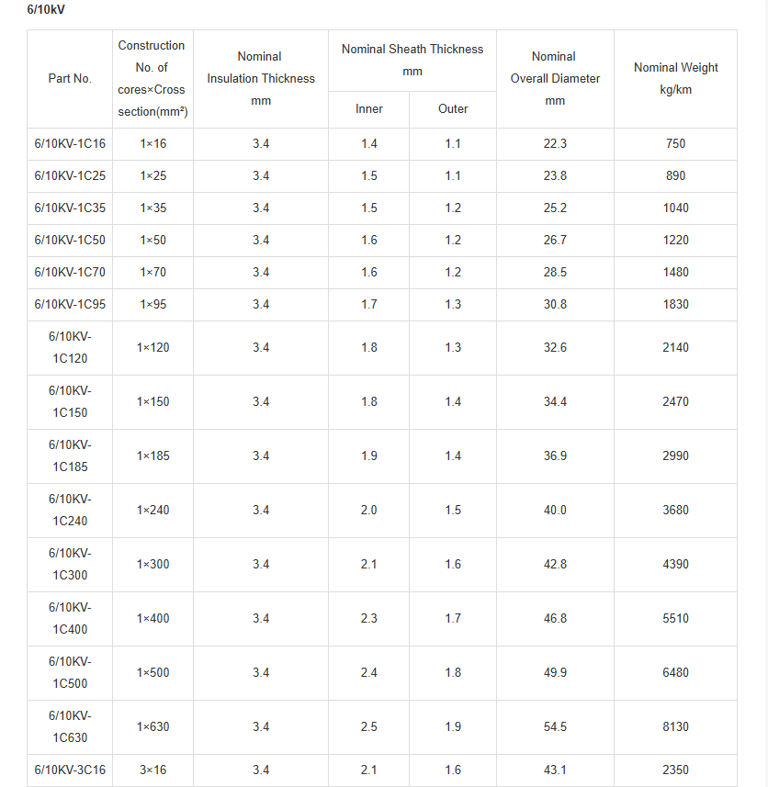

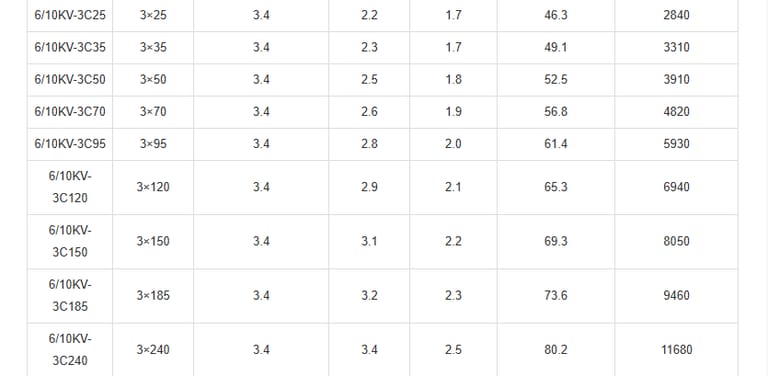

Characteristics of 6/10kV Rated Cables

Stepping up in voltage, the 6/10kV cables cater to main propulsion systems and higher-power demands on medium-sized ships. Insulation thickness is uniformly 3.4mm across single-core sizes from 1×16mm² to 1×630mm². The 6/10KV-1C16 measures 22.3mm in diameter and weighs 750kg/km, while the largest, 1×630mm², hits 54.5mm and 8130kg/km. Sheath thicknesses increase with size: inner from 1.4mm to 2.5mm, outer from 1.1mm to 1.9mm.

For three-core options, spanning 3×16mm² to 3×240mm², diameters range from 43.1mm (2350kg/km) to 80.2mm (11680kg/km). The consistent 3.4mm XLPE insulation provides enhanced dielectric withstand, suitable for longer cable runs with minimal voltage drop.

Advantages include superior thermal endurance, allowing operation in engine compartments where ambient temperatures can fluctuate. The flame retardant design, combined with armoured protection, reduces fault propagation risks. In South African contexts, these cables are ideal for retrofitting older vessels in Richards Bay shipyards, where upgrading to efficient power distribution minimises downtime.

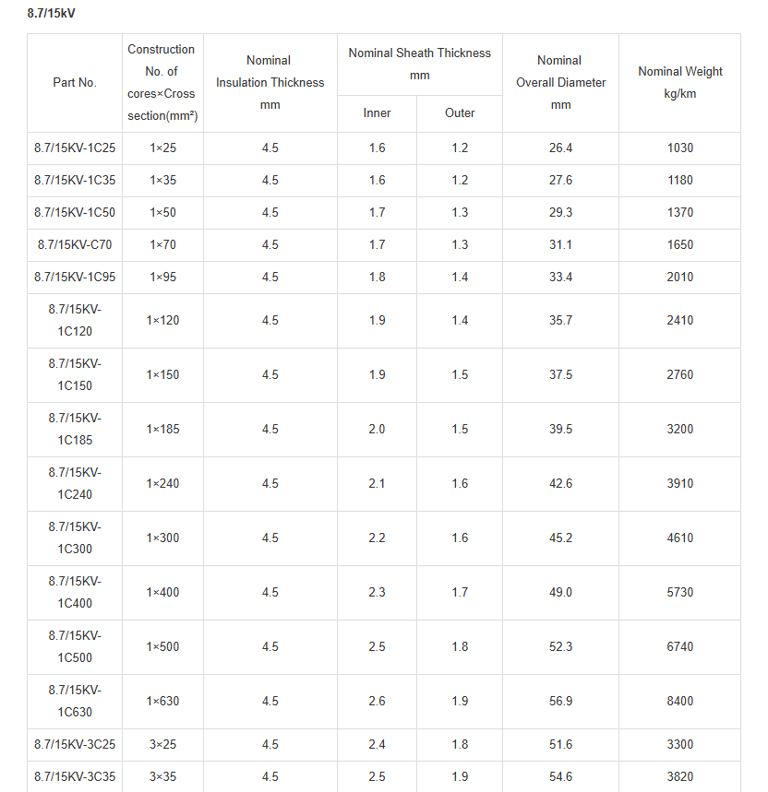

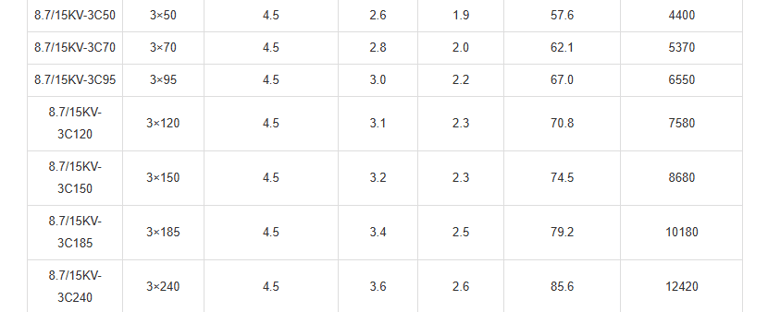

Characteristics of 8.7/15kV Rated Cables

The highest voltage in this series, 8.7/15kV cables, are engineered for primary power distribution on large ocean-going vessels, such as container ships or tankers. With a 4.5mm insulation thickness, single-core models from 1×25mm² to 1×630mm² start at 26.4mm diameter (1030kg/km) and peak at 56.9mm (8400kg/km). Sheaths thicken progressively: inner 1.6mm to 2.6mm, outer 1.2mm to 1.9mm.

Three-core variants, from 3×25mm² to 3×240mm², have diameters from 51.6mm (3300kg/km) to 85.6mm (12420kg/km). The robust XLPE layer ensures high impulse withstand voltage, vital for surge protection in stormy seas.

These cables' advantages lie in their capacity for high-power transmission with low losses, supported by the metallic screen's grounding efficiency. Flame retardant and LSOH properties are amplified here, offering peace of mind in high-stakes environments. Their armour withstands severe mechanical abuse, such as from cargo handling equipment.

Advantages and Performance Insights

Across all voltage ratings, these XLPE insulated, LSOH sheathed armoured flame retardant MV power cables offer multifaceted advantages. Firstly, safety is enhanced through flame retardancy, which prevents fire spread in bunched installations, as per IEC 60332-3-22. Low smoke emission (IEC 61034) ensures visibility during emergencies, while halogen-free composition (IEC 60754) avoids corrosive gases that could damage equipment or harm personnel.

Durability stems from the armour, which provides crush resistance and electromagnetic compatibility, reducing interference in sensitive navigation systems. XLPE insulation's high dielectric constant and low dissipation factor enable efficient power transfer, with thermal ratings supporting continuous operation at 80°C.

Environmentally, these cables align with sustainable practices by minimising hazardous materials, appealing to South African operators under the National Environmental Management Act. Cost-wise, their longevity reduces maintenance needs, offsetting initial investments.

In performance terms, the cables' bending radii facilitate installation in confined spaces, while weight considerations aid in vessel balance calculations. Compared to non-armoured alternatives, they offer superior fault tolerance.

Conclusion

The 3.6/6kV, 6/10kV, and 8.7/15kV XLPE insulated, LSOH (SHF1) sheathed armoured flame retardant MV power cables represent a pinnacle of marine electrical engineering. Their construction, adhering to IEC standards, combines advanced materials like XLPE and LSOH with protective armour, delivering unmatched safety, durability, and performance. In South Africa, where maritime trade is a economic cornerstone, these cables enable reliable power distribution, mitigating risks in demanding environments.

As shipping evolves towards electrification and sustainability, these innovations provide valuable insights for future designs. Engineers and operators are encouraged to consider these specifications for optimal vessel performance, ensuring safety at sea remains uncompromised.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430