Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

450/750V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

450/750V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

FTX100 07Z1-U/R/K (CU/LSZH 450/750V Class 1/2/5)

HAR Code: H07Z1-U/R/K

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS EN 50525-3-31

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

450/750V

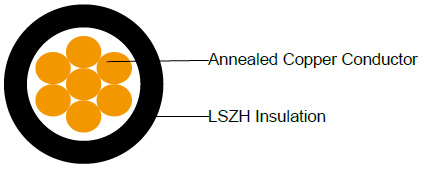

CABLE CONSTRUCTION

Conductor : Copper conductor according to BS EN 60228 class 1/2/5.

H07Z1-U : 1.5-10mm2 Class 1 solid copper conductor to BS EN 60228.

H07Z1-R : 1.5-630mm2 Class 2 stranded copper conductor to BS EN 60228.

H07Z1-K : 1.5-240mm2 Class 5 stranded copper conductor to BS EN 60228.

Insulation : Thermoplastic compound of type TI 7 to EN 50363-7.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 70°C

Maximum short circuit temperature (5 Seconds) : 160°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX100 07Z1-U/R/K | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

1×1.5 | 1 | 0.7 | 2.6 | 3.2 | 22 |

1×2.5 | 1 | 0.8 | 3.2 | 3.9 | 35 |

1×4 | 1 | 0.8 | 3.6 | 4.4 | 52 |

1×6 | 1 | 0.8 | 4.1 | 5.0 | 73 |

1×10 | 1 | 1.0 | 5.3 | 6.4 | 122 |

1×1.5 | 2 | 0.7 | 2.7 | 3.3 | 24 |

1×2.5 | 2 | 0.8 | 3.3 | 4.0 | 37 |

1×4 | 2 | 0.8 | 3.8 | 4.6 | 54 |

1×6 | 2 | 0.8 | 4.3 | 5.2 | 76 |

1×10 | 2 | 1.0 | 5.6 | 6.7 | 127 |

1×16 | 2 | 1.0 | 6.4 | 7.8 | 191 |

1×25 | 2 | 1.2 | 8.1 | 9.7 | 301 |

1×35 | 2 | 1.2 | 9.0 | 10.9 | 405 |

1×50 | 2 | 1.4 | 10.6 | 12.8 | 550 |

1×70 | 2 | 1.4 | 12.1 | 14.6 | 774 |

1×95 | 2 | 1.6 | 14.1 | 17.1 | 1069 |

1×120 | 2 | 1.6 | 15.6 | 18.8 | 1333 |

1×150 | 2 | 1.8 | 17.3 | 20.9 | 1640 |

1×185 | 2 | 2.0 | 19.3 | 23.3 | 2055 |

1×240 | 2 | 2.2 | 22.0 | 26.6 | 2690 |

1×300 | 2 | 2.4 | 24.5 | 29.6 | 3364 |

1×400 | 2 | 2.6 | 27.5 | 33.2 | 4252 |

1×500 | 2 | 2.8 | 30.5 | 36.9 | 5343 |

1×630 | 2 | 2.8 | 34.0 | 41.1 | 6868 |

1×1.5 | 5 | 0.7 | 2.8 | 3.4 | 23 |

1×2.5 | 5 | 0.8 | 3.4 | 4.1 | 37 |

1×4 | 5 | 0.8 | 3.9 | 4.8 | 54 |

1×6 | 5 | 0.8 | 4.4 | 5.3 | 76 |

1×10 | 5 | 1.0 | 5.7 | 6.8 | 128 |

1×16 | 5 | 1.0 | 6.7 | 8.1 | 191 |

1×25 | 5 | 1.2 | 8.4 | 10.2 | 297 |

1×35 | 5 | 1.2 | 9.7 | 11.7 | 403 |

1×50 | 5 | 1.4 | 11.5 | 13.9 | 577 |

1×70 | 5 | 1.4 | 13.2 | 16.0 | 803 |

1×95 | 5 | 1.6 | 15.1 | 18.2 | 1066 |

1×120 | 5 | 1.6 | 16.7 | 20.2 | 1332 |

1×150 | 5 | 1.8 | 18.6 | 22.5 | 1660 |

1×185 | 5 | 2.0 | 20.6 | 24.9 | 2030 |

1×240 | 5 | 2.2 | 23.5 | 28.4 | 2659 |

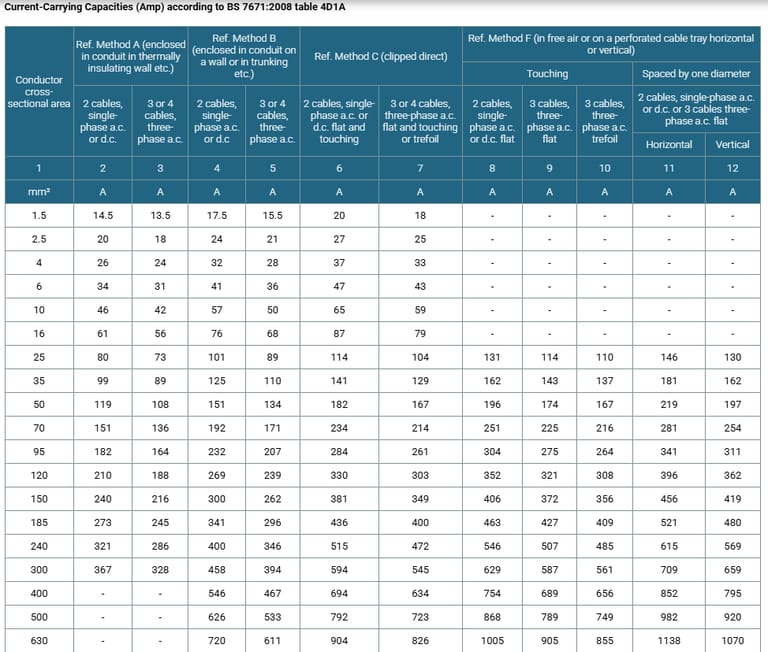

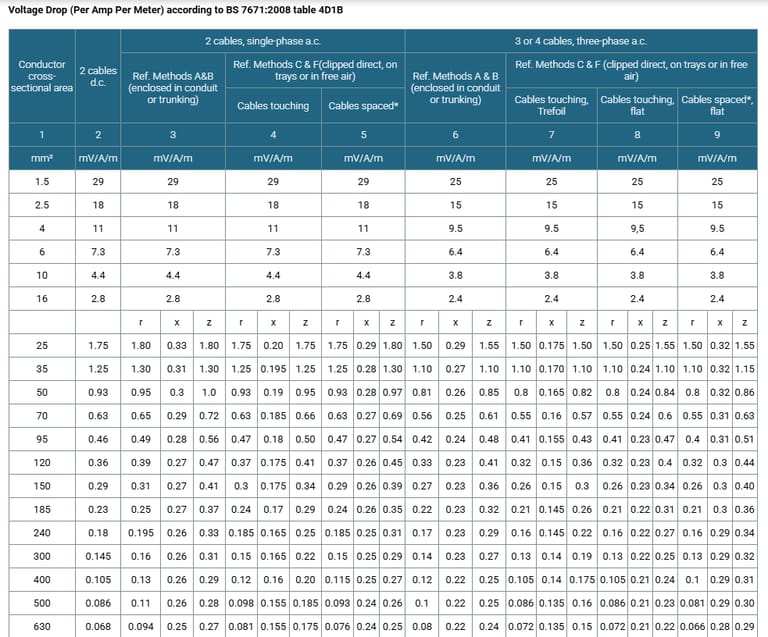

ELECTRICAL PROPERTIES

Conductor operating temperature : 70°C

Ambient temperature : 30°C

What Are 450/750V LSZH Insulated, Non-Sheathed Power Cables?

The 450/750V LSZH insulated, non-sheathed power cables are single-core cables designed for low-voltage power distribution in environments requiring enhanced safety features. The designation 450/750V indicates their voltage rating, suitable for systems with a nominal voltage up to 450V to ground and 750V between conductors. The LSZH insulation, made from a thermoplastic compound (Type TI 7), ensures that the cables emit minimal smoke and no halogen gases when exposed to fire, reducing health and environmental risks.

These cables come in three conductor classes as per BS EN 60228:

H07Z1-U: Solid copper conductor (Class 1, 1.5–10 mm²).

H07Z1-R: Stranded copper conductor (Class 2, 1.5–630 mm²).

H07Z1-K: Flexible stranded copper conductor (Class 5, 1.5–240 mm²).

The absence of a sheath makes these cables lightweight and flexible, ideal for internal wiring or conduit installations. Optional features like UV resistance, hydrocarbon resistance, oil resistance, anti-rodent, and anti-termite properties enhance their versatility for specialized applications.

Standards and Fire Performance

The cables adhere to BS EN 50525-3-31, a European standard ensuring consistent quality and performance. They also meet stringent fire performance standards, making them suitable for high-risk environments:

Flame Retardance: Tested to IEC 60332-1-2 and EN 60332-1-2, ensuring the cable resists flame spread in a single vertical wire test.

Reduced Fire Propagation: Compliant with IEC 60332-3-24 and EN 60332-3-24 for bundled cables, minimizing fire spread in densely wired setups.

Halogen-Free: Meets IEC 60754-1 and EN 50267-2-1, ensuring no halogen gas emissions, which are toxic and corrosive.

No Corrosive Gas Emission: Certified to IEC 60754-2 and EN 50267-2-2, reducing damage to equipment and health risks.

Minimum Smoke Emission: Tested to IEC 61034-2 and EN 61034-2, ensuring low smoke output for better visibility during evacuation.

These properties make the cables ideal for South African industries, where fire safety regulations are stringent, particularly in mining and petrochemical sectors.

The 450/750V LSZH insulated, non-sheathed power cables to BS EN 50525-3-31 represent a pinnacle of safety and performance in electrical engineering. Their halogen-free, low smoke, and flame-retardant properties make them indispensable in high-risk environments like South Africa’s mining and petrochemical industries. By adhering to rigorous standards and offering versatile conductor classes, these cables meet the needs of modern infrastructure while ensuring compliance with safety regulations.

As South Africa continues to advance its industrial capabilities, the adoption of LSZH cables will play a crucial role in enhancing safety, sustainability, and efficiency. Whether powering a gold mine in Gauteng or a petrochemical plant in Mpumalanga, these cables are a testament to the intersection of technology and safety in the 21st century.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430