Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

450/750V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

450/750V Mica+LSZH insulated, Non-sheathed Power Cables Compliant with BS EN 50525-3-31: Ideal for South Africa’s Mining and Heavy Industries, Offering Fire Resistance, Safety, and Durability

450/750V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

FFX100 07mZ1-U/R/K (CU/MGT+LSZH 450/750V Class 1/2/5)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS EN 50525-3-31

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

450/750V

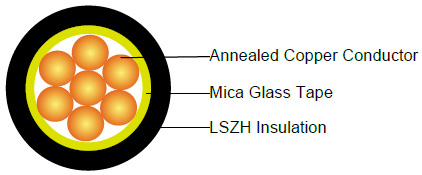

CABLE CONSTRUCTION

Conductor : Copper conductor according to BS EN 60228 class 1/2/5.

FFX100 07mZ1-U : 1.5-10mm² Class 1 solid copper conductor to BS EN 60228.

FFX100 07mZ1-R : 1.5-630mm² Class 2 stranded copper conductor to BS EN 60228.

FFX100 07mZ1-K : 1.5-240mm² Class 5 stranded copper conductor to BS EN 60228.

Fire Barrier : Mica glass tape.

Insulation : Thermoplastic compound of type TI 7 to EN 50363-7.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 70°C

Maximum short circuit temperature (5 Seconds) : 160°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX100 07mZ1-U/R/K | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

1×1.5 | 1 | 0.7 | 3.6 | 4.2 | 26 |

1×2.5 | 1 | 0.8 | 4.2 | 4.9 | 40 |

1×4 | 1 | 0.8 | 4.6 | 5.4 | 57 |

1×6 | 1 | 0.8 | 5.1 | 6.0 | 78 |

1×10 | 1 | 1.0 | 6.3 | 7.4 | 128 |

1×1.5 | 2 | 0.7 | 3.7 | 4.3 | 28 |

1×2.5 | 2 | 0.8 | 4.3 | 5.0 | 42 |

1×4 | 2 | 0.8 | 4.8 | 5.6 | 59 |

1×6 | 2 | 0.8 | 5.3 | 6.2 | 81 |

1×10 | 2 | 1.0 | 6.6 | 7.7 | 133 |

1×16 | 2 | 1.0 | 7.4 | 8.8 | 197 |

1×25 | 2 | 1.2 | 9.1 | 10.7 | 308 |

1×35 | 2 | 1.2 | 10.0 | 11.9 | 412 |

1×50 | 2 | 1.4 | 11.6 | 13.8 | 558 |

1×70 | 2 | 1.4 | 13.1 | 15.6 | 782 |

1×95 | 2 | 1.6 | 15.1 | 18.1 | 1078 |

1×120 | 2 | 1.6 | 16.6 | 19.8 | 1342 |

1×150 | 2 | 1.8 | 18.3 | 21.9 | 1650 |

1×185 | 2 | 2.0 | 20.3 | 24.3 | 2067 |

1×240 | 2 | 2.2 | 23 | 27.6 | 2703 |

1×300 | 2 | 2.4 | 25.5 | 30.6 | 3378 |

1×400 | 2 | 2.6 | 28.5 | 34.2 | 4267 |

1×500 | 2 | 2.8 | 31.5 | 37.9 | 5359 |

1×630 | 2 | 2.8 | 35 | 42.1 | 6884 |

1×1.5 | 5 | 0.7 | 3.8 | 4.4 | 27 |

1×2.5 | 5 | 0.8 | 4.4 | 5.1 | 42 |

1×4 | 5 | 0.8 | 4.9 | 5.8 | 59 |

1×6 | 5 | 0.8 | 5.4 | 6.3 | 81 |

1×10 | 5 | 1.0 | 6.7 | 7.8 | 134 |

1×16 | 5 | 1.0 | 7.7 | 9.1 | 197 |

1×25 | 5 | 1.2 | 9.4 | 11.2 | 304 |

1×35 | 5 | 1.2 | 10.7 | 12.7 | 410 |

1×50 | 5 | 1.4 | 12.5 | 14.9 | 585 |

1×70 | 5 | 1.4 | 14.2 | 17.0 | 811 |

1×95 | 5 | 1.6 | 16.1 | 19.2 | 1075 |

1×120 | 5 | 1.6 | 17.7 | 21.2 | 1341 |

1×150 | 5 | 1.8 | 19.6 | 23.5 | 1670 |

1×185 | 5 | 2.0 | 21.6 | 25.9 | 2042 |

1×240 | 5 | 2.2 | 24.5 | 29.4 | 2672 |

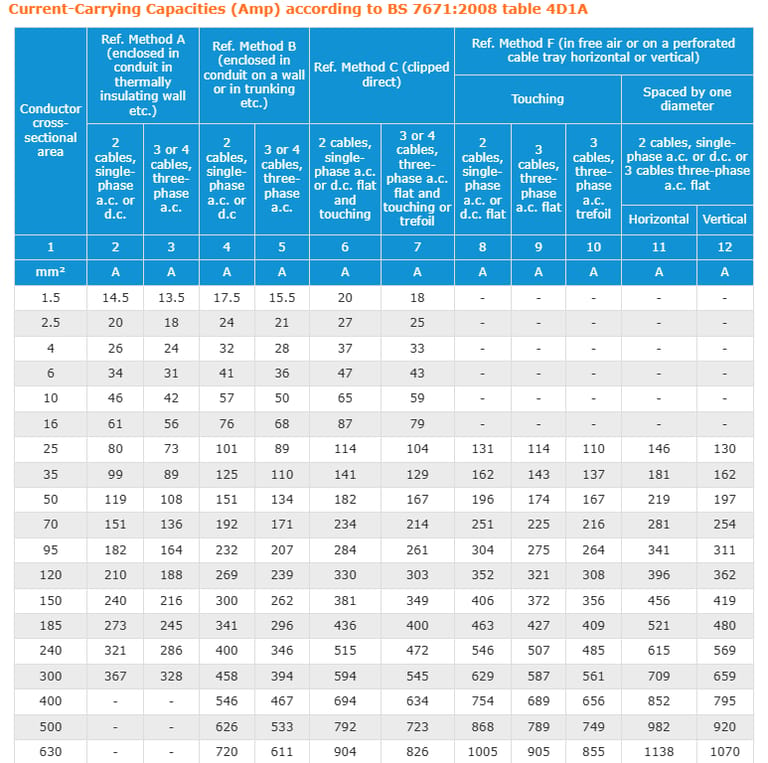

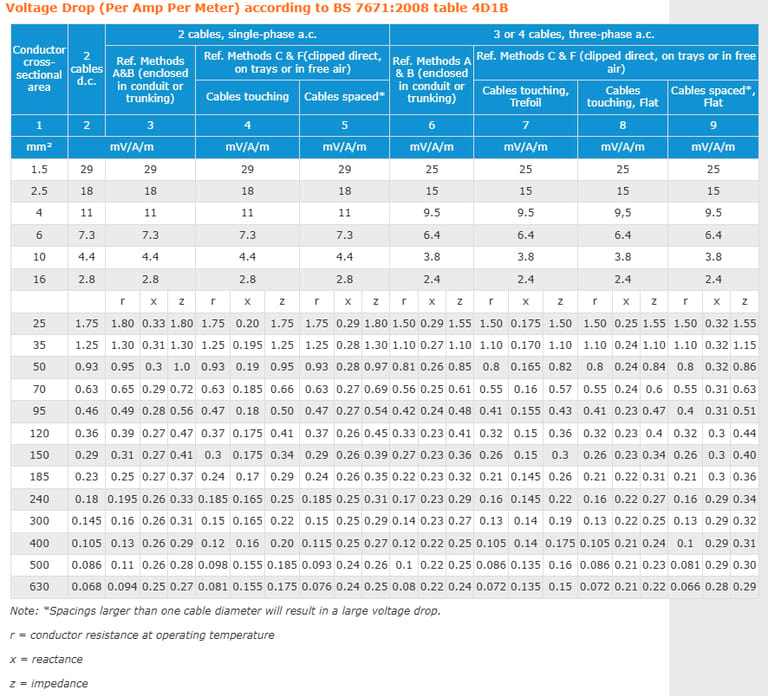

ELECTRICAL PROPERTIES

Conductor operating temperature : 70°C

Ambient temperature : 30°C

What Are 450/750V Mica+LSZH Insulated Power Cables?

The 450/750V Mica+LSZH insulated, non-sheathed power cables are single-core cables designed for low-voltage applications, with a voltage rating of 450V (phase-to-ground) and 750V (phase-to-phase). The designation FFX100 07mZ1-U/R/K refers to their specific construction, where:

U indicates a solid copper conductor (Class 1).

R denotes a stranded copper conductor (Class 2).

K signifies a flexible stranded copper conductor (Class 5).

These cables are built to comply with BS EN 50525-3-31, a European standard that ensures safety, reliability, and performance in low-voltage power distribution. The cables feature a copper conductor, a mica glass tape fire barrier, and low smoke zero halogen (LSZH) insulation, making them ideal for environments where fire safety and minimal toxic emissions are critical.

Key Features

Voltage Rating: 450/750V, suitable for low-voltage power systems.

Conductor Types: Available in Class 1 (solid), Class 2 (stranded), and Class 5 (flexible) copper conductors, per BS EN 60228.

Fire Barrier: Mica glass tape provides exceptional circuit integrity under fire conditions.

Insulation: Thermoplastic LSZH compound (type TI 7, per EN 50363-7) minimizes smoke and toxic gas emissions.

Optional Sheath Properties: UV resistance, hydrocarbon resistance, oil resistance, anti-rodent, and anti-termite features can be added.

Fire Performance: A Game-Changer for Safety

One of the standout features of these cables is their exceptional fire performance, making them a preferred choice in high-risk environments like South Africa’s mining and heavy industries. The cables meet stringent fire safety standards, including:

Circuit Integrity: Compliant with IEC 60331-21, BS 6387, and BS 8491, ensuring the cables maintain functionality during a fire, critical for emergency systems.

Flame Retardance: Passes IEC 60332-1-2 and EN 60332-1-2 single vertical wire tests, preventing flame spread.

Reduced Fire Propagation: Meets IEC 60332-3-24 and EN 60332-3-24 for bundled cables, reducing the risk of fire spreading in densely cabled areas.

Halogen-Free: Complies with IEC 60754-1 and EN 50267-2-1, ensuring no halogen gas emissions, which can be toxic and corrosive.

Low Smoke Emission: Adheres to IEC 61034-2 and EN 61034-2, minimizing smoke production for better visibility during evacuations.

No Corrosive Gas Emission: Meets IEC 60754-2 and EN 50267-2-2, reducing damage to equipment and health risks.

Applications in South Africa’s Mining and Heavy Industries

South Africa’s mining sector, a backbone of the economy, relies heavily on robust electrical infrastructure to power operations in challenging underground environments. The 450/750V Mica+LSZH cables are particularly suited for:

Underground Mining: Their fire-resistant and low-smoke properties ensure safety in confined spaces, where fire hazards are a significant risk. The cables’ circuit integrity supports critical systems like ventilation and emergency lighting during fires.

Petrochemical Plants: In facilities handling flammable materials, the cables’ halogen-free and flame-retardant properties reduce risks.

High-Rise Buildings: Used in fire alarm and evacuation systems, ensuring reliability during emergencies.

Hospitals and Airports: Low smoke emissions enhance visibility and safety for evacuations.

Compliance with BS EN 50525-3-31

The BS EN 50525-3-31 standard ensures that these cables meet rigorous safety and performance requirements for low-voltage applications. Key aspects include:

Conductor Standards: Compliance with BS EN 60228 for copper conductors.

Insulation Standards: Use of EN 50363-7 type TI 7 thermoplastic compound.

Fire Safety: Adherence to international fire performance standards, ensuring reliability in emergencies.

This compliance makes the cables a trusted choice for engineers and facility managers worldwide, including in South Africa’s stringent regulatory environment.

Frequently Asked Questions

1. What makes Mica+LSZH cables different from standard cables?

Mica+LSZH cables feature a mica glass tape fire barrier for circuit integrity and LSZH insulation to minimize smoke and toxic gas emissions, unlike standard PVC cables, which may emit harmful gases when burned.

2. Are these cables suitable for outdoor use?

Yes, with optional UV-resistant sheaths, they can withstand South Africa’s harsh sunlight, making them ideal for outdoor mining and industrial applications.

3. How do I choose the right conductor class?

Class 1 (solid): Best for fixed installations with minimal movement.

Class 2 (stranded): Suitable for general-purpose applications with moderate flexibility.

Class 5 (flexible): Ideal for installations requiring frequent movement or vibration resistance, common in automated systems.

4. Can these cables handle South Africa’s power fluctuations?

Their robust construction and 450/750V rating make them resilient to voltage fluctuations common in South Africa’s grid, ensuring reliable performance.

5. What is the lifespan of these cables?

With proper installation and maintenance, these cables can last over 25 years, even in harsh environments, due to their durable materials and optional protective sheaths.

The 450/750V Mica+LSZH insulated, non-sheathed power cables compliant with BS EN 50525-3-31 are a vital asset for South Africa’s mining and heavy industries. Their fire-resistant, low-smoke, and halogen-free properties ensure safety in high-risk environments, while their robust construction supports reliable power distribution. From underground gold mines to steel plants, these cables address critical safety and performance needs, aligning with global standards and local trends. By choosing these cables, industries can enhance safety, comply with regulations, and build resilient infrastructure for the future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430