Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

450/750V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

Exploring the Versatility of 450/750V Mica+LSZH Insulated Power Cables in Modern Infrastructure

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS EN 50525-3-41(formerly BS 7211)

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

450/750V

CABLE CONSTRUCTION

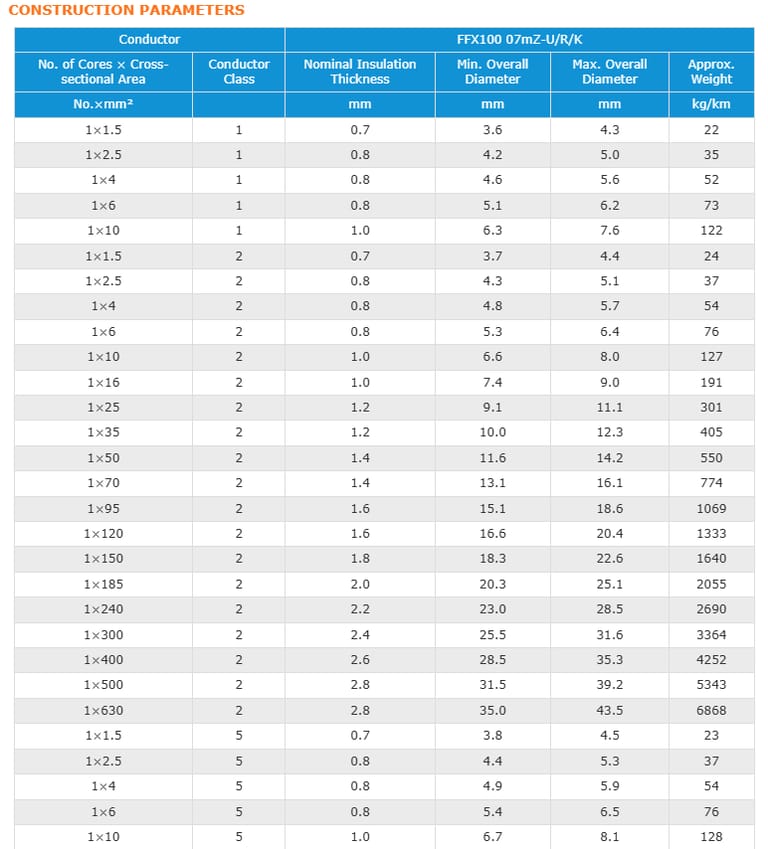

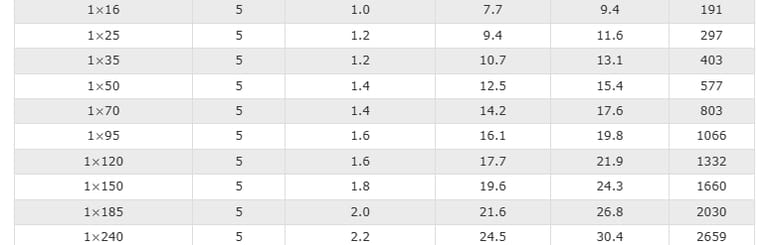

Conductor : Copper conductor according to BS EN 60228 class 1/2/5.

FFX100 07mZ-U : 1.5-10mm² Class 1 solid copper conductor to BS EN 60228.

FFX100 07mZ-R : 1.5-630mm² Class 2 stranded copper conductor to BS EN 60228.

FFX100 07mZ-K : 1.5-240mm² Class 5 stranded copper conductor to BS EN 60228.

Fire Barrier : Mica glass tape.

Insulation : Crosslinked polyolefin material type EI 5 according to EN 50363-5.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow.

PHYSICAL AND THERMAL PROPERTIES

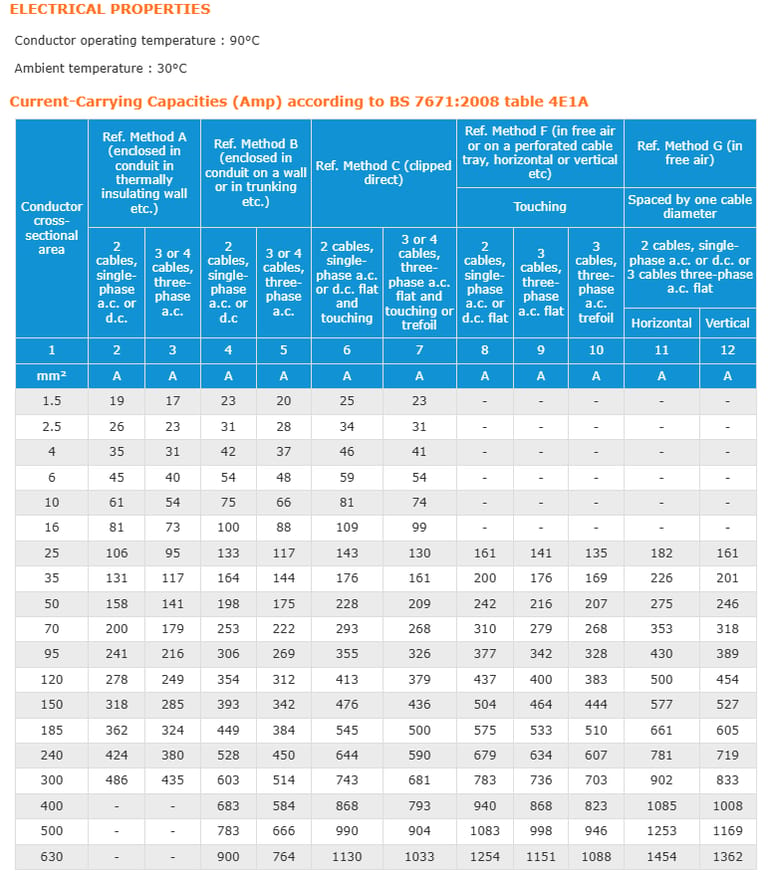

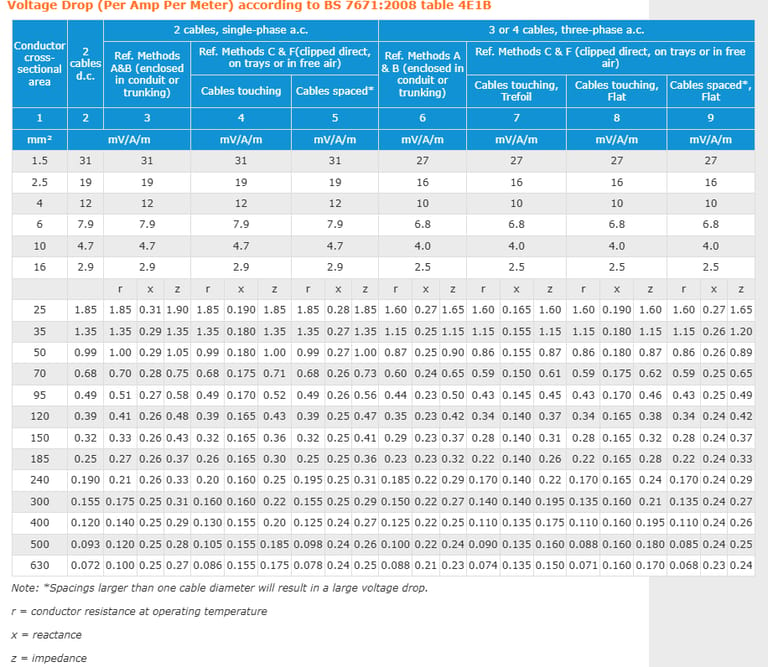

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

Introduction to 450/750V Mica+LSZH Power Cables

In the realm of electrical engineering, the 450/750V Mica+LSZH insulated, non-sheathed power cables to BS EN 50525-3-41 (single core) stand out as a pinnacle of safety and reliability. These cables, designed for critical applications, combine fire-resistant mica tape with low smoke zero halogen (LSZH) insulation, making them ideal for environments where safety and performance are paramount. From power stations to high-rise buildings, these cables ensure uninterrupted power delivery while minimizing risks associated with fire and toxic emissions. This article delves into their specifications, standards, usage scenarios, and their relevance in South Africa’s evolving infrastructure landscape, supported by case studies and answers to frequently asked questions.

Standards and Fire Performance

The cables are adapted from BS EN 50525-3-41 (formerly BS 7211), ensuring compliance with stringent international standards. Their fire performance is exceptional, making them a preferred choice for safety-critical applications:

Circuit Integrity: Meets IEC 60331-21, BS 6387, and BS 8491, ensuring functionality during fires.

Flame Retardance: Complies with IEC 60332-1-2 and EN 60332-1-2, preventing fire propagation.

Halogen-Free: Adheres to IEC 60754-1 and EN 50267-2-1, eliminating toxic halogen gas emissions.

Low Smoke Emission: Certified under IEC 61034-2 and EN 61034-2, ensuring visibility in fire scenarios.

Non-Corrosive Gas Emission: Meets IEC 60754-2 and EN 50267-2-2, protecting equipment and personnel.

These properties make the cables ideal for environments where human safety and equipment protection are critical, such as hospitals and mass transit systems.

Usage Scenarios

The versatility of 450/750V Mica+LSZH cables makes them indispensable across various sectors:

Power Stations: Their high current-carrying capacity and fire resistance ensure reliable power distribution in high-risk environments.

Mass Transit Systems: Used in underground passenger systems, these cables maintain circuit integrity during emergencies, facilitating safe evacuations.

Airports: The cables’ low smoke and halogen-free properties are critical in crowded terminals where visibility and air quality are vital during fires.

Petrochemical Plants: Optional hydrocarbon and oil-resistant sheaths make them suitable for harsh chemical environments.

Hotels and Hospitals: Their safety features protect occupants in densely populated buildings.

High-Rise Buildings: The cables’ ability to maintain power during fires supports critical systems like elevators and emergency lighting.

Frequently Asked Questions

What makes Mica+LSZH cables different from standard cables?

Unlike standard cables, Mica+LSZH cables feature a mica tape fire barrier and LSZH insulation, reducing smoke and toxic gas emissions during fires, making them ideal for safety-critical environments.

Are these cables suitable for outdoor use?

Yes, with optional UV-resistant sheaths, they can withstand prolonged exposure to sunlight, as demonstrated in the Cape Town stadium retrofit.

What conductor class should I choose?

Class 1: Best for fixed installations with minimal movement.

Class 2: Suitable for general-purpose applications requiring some flexibility.

Class 5: Ideal for applications needing high flexibility, such as temporary setups.

How do these cables contribute to safety in South Africa?

Their fire-resistant and low-smoke properties enhance safety in crowded urban settings, supporting South Africa’s infrastructure safety goals.

Can these cables be used in petrochemical plants?

Yes, optional hydrocarbon and oil-resistant sheaths make them suitable for harsh chemical environments.

The 450/750V Mica+LSZH insulated, non-sheathed power cables to BS EN 50525-3-41 are a cornerstone of modern electrical infrastructure. Their robust construction, compliance with stringent standards, and versatility make them indispensable in critical applications worldwide, including South Africa’s evolving urban landscape. From ensuring safety in metro systems to supporting sustainable stadium retrofits, these cables exemplify the blend of innovation and reliability needed for 21st-century infrastructure. As South Africa continues to address its electrical challenges, the adoption of such advanced cable technology will play a pivotal role in building safer, more resilient systems.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430