Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

450/750V Mica+XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-5 Cores)

Unveiling the Power of 450/750V Mica+XLPE Insulated, LSZH Sheathed Power Cables

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS 7211:2012

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

450/750V

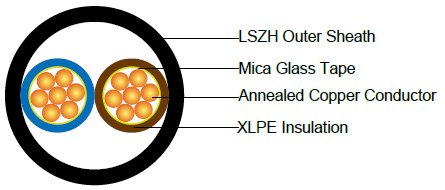

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, solid or stranded according to BS EN 60228 class 1 or class 2.

Fire Barrier : Mica glass tape.

Insulation : XLPE type GP 8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 can be offered as option.

Inner Covering Option : The optional inner covering, where used, shall consist of an extruded layer of synthetic polymeric material. It shall surround the laid-up two, three, four or five cores, giving the assembly a practically circular shape.

Outer Sheath : Extruded LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

2-core : Brown and blue.

3-core : Brown, black and grey.

4-core : Blue, brown black and grey.

5-core : Green/yellow, blue, brown black and grey.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

Conductor cross-sectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | A | A | A | A | A | A | A | A |

1.0 | 14.5 | 13 | 17 | 15 | 19 | 17 | 21 | 18 |

1.5 | 18.5 | 16.5 | 22 | 19.5 | 24 | 22 | 26 | 23 |

2.5 | 25 | 22 | 30 | 26 | 33 | 30 | 36 | 32 |

4 | 33 | 30 | 40 | 35 | 45 | 40 | 49 | 42 |

6 | 42 | 38 | 51 | 44 | 58 | 52 | 63 | 54 |

10 | 57 | 51 | 69 | 60 | 80 | 71 | 86 | 75 |

16 | 76 | 68 | 91 | 80 | 107 | 96 | 115 | 100 |

25 | 99 | 89 | 119 | 105 | 138 | 119 | 149 | 127 |

35 | 121 | 109 | 146 | 128 | 171 | 147 | 185 | 158 |

Note: *With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

Conductor cross-sectional area | Two-core cable, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm² | mV/A/m | mV/A/m | mV/A/m | ||||

1.0 | 46 | 46 | 40 | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4 | 12 | 12 | 10 | ||||

6 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

r | x | z | r | x | z | ||

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

Introduction to Fire-Resistant Power Cables

In the world of electrical engineering, safety and reliability are paramount. The 450/750V Mica+XLPE Insulated, Low Smoke Zero Halogen (LSZH) Sheathed Power Cables, designed to meet BS 7211 standards, are a cornerstone in applications where fire safety and circuit integrity are critical. These cables, known for their robust construction and fire-resistant properties, are widely used in high-risk environments like power stations, airports, hospitals, and high-rise buildings. In South Africa, where rapid urbanization and infrastructure development are driving demand for advanced electrical solutions, these cables play a vital role.

Standards Compliance

The cables adhere to stringent international standards, ensuring safety and performance:

BS 7211:2012: Specifies requirements for XLPE-insulated, LSZH-sheathed cables for low-voltage applications.

IEC 60331-21 and BS 6387: Ensure circuit integrity under fire conditions.

IEC 60332-1-2 and EN 60332-1-2: Confirm flame retardance for single cables.

IEC 60332-3-24 and EN 60332-3-24: Verify reduced fire propagation for bundled cables.

IEC 60754-1 and EN 50267-2-1: Guarantee halogen-free properties, reducing toxic gas emissions.

IEC 60754-2 and EN 50267-2-2: Ensure no corrosive gas emissions.

IEC 61034-2 and EN 61034-2: Minimize smoke emission, enhancing visibility during emergencies.

Usage Scenarios

The 450/750V Mica+XLPE Insulated, LSZH Sheathed Power Cables are designed for fixed installations in high-risk environments, including:

Power Stations: Ensuring reliable power distribution under high thermal and electrical stress.

Mass Transit Systems: Used in underground passenger systems for lighting, signaling, and control circuits, where low smoke emissions are crucial.

Airports: Powering critical systems like runway lighting and control towers, where circuit integrity is vital during emergencies.

Petrochemical Plants: Resistant to hydrocarbons and oils, ideal for harsh industrial settings.

Hospitals and High-Rise Buildings: Providing safe power for emergency systems, such as fire alarms and sprinklers, minimizing risks to occupants.

In South Africa, these cables are increasingly adopted in urban infrastructure projects due to their fire-resistant and low-smoke properties, aligning with the country’s focus on safety in densely populated areas.

The 450/750V Mica+XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-5 Cores) represent a pinnacle of safety and performance in low-voltage power distribution. Their robust construction, compliance with international standards, and suitability for high-risk environments make them indispensable in applications from power stations to high-rise buildings. In South Africa, where urbanization and safety regulations are shaping infrastructure, these cables are a critical component in projects like airport expansions and industrial upgrades. By combining fire resistance, low smoke emissions, and durability, they offer a reliable solution for modern electrical challenges, ensuring safety and efficiency for years to come.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430