Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

450/750V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (2-5 Cores)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is TUV approved.

STANDARDS

Basic design to BS 7211:2012

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

450/750V

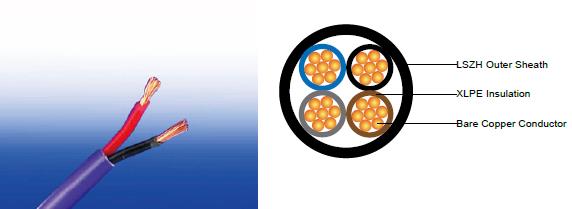

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, solid or stranded according to BS EN 60228 class 1 or class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 can be offered as option.

Inner Covering Option : The optional inner covering, where used, shall consist of an extruded layer of synthetic polymeric material. It shall surround the laid-up two, three, four or five cores, giving the assembly a practically circular shape.

Outer Sheath : Extruded LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

2-core : Brown and blue.

3-core : Brown, black and grey.

4-core : Blue, brown, black and grey.

5-core : Green/yellow, blue, brown black and grey.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

Introduction

In the realm of electrical engineering, the selection of appropriate cabling systems is paramount for ensuring safety, reliability, and efficiency in power distribution. Among the myriad options available, 450/750V XLPE insulated, LSZH sheathed power cables compliant with BS 7211 stand out for their robust design and enhanced safety features. These cables, typically featuring 2 to 5 cores, are engineered to meet the demanding requirements of modern infrastructure, particularly in environments where fire safety is critical. Cross-linked polyethylene (XLPE) insulation provides excellent electrical properties, while the low smoke zero halogen (LSZH) sheath minimises toxic emissions during combustion, making them ideal for densely populated or confined spaces.

The British Standard BS 7211:2012 outlines the basic design parameters for these thermosetting insulated, non-armoured cables with a voltage rating of 450/750V. This standard ensures consistency in manufacturing and performance, aligning with international norms such as those from the International Electrotechnical Commission (IEC). In South Africa, where rapid urbanisation and infrastructure development are ongoing, these cables have gained prominence due to stringent building regulations and a focus on public safety. The National Regulator for Compulsory Specifications (NRCS) and standards from the South African Bureau of Standards (SABS) often reference or harmonise with BS 7211, promoting the use of fire-retardant materials in high-risk installations.

Fire Performance and Safety Features

One of the standout attributes of these cables is their exceptional fire performance, which is crucial in preventing catastrophic failures in fire-prone settings. Compliant with IEC 60332-1-2 and EN 60332-1-2 for flame retardance in single vertical wire tests, they resist ignition and self-extinguish rapidly. For bundled configurations, reduced fire propagation is ensured per IEC 60332-3-24 and EN 60332-3-24.

The LSZH sheath excels in halogen-free properties (IEC 60754-1; EN 50267-2-1), emitting no corrosive gases (IEC 60754-2; EN 50267-2-2) and minimal smoke (IEC 61034-2; EN 61034-2). This is vital in enclosed spaces, as traditional PVC cables release toxic halogens like chlorine, forming hydrochloric acid that can damage equipment and harm occupants.

In analytical terms, the absence of halogens reduces smoke density by up to 80% compared to halogenated alternatives, facilitating visibility during evacuations. Corrosive gas emissions are below 0.5% acidity, minimising secondary damage to electronics and structures.

South African regulations, such as SANS 10142-1 (The Wiring of Premises), increasingly mandate LSZH cables in public buildings to align with global safety standards. This shift is driven by incidents like the 2024 Durban hospital fire, where smoke inhalation was a major cause of casualties, highlighting the life-saving potential of these cables.

Usage Scenarios and Applications

These cables are primarily deployed in power stations, mass transit systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. Their LSZH properties make them indispensable where human safety is prioritised, such as underground passenger systems or healthcare facilities.

In power stations, they handle control and auxiliary power with reliability under high temperatures. Airports utilise them for lighting and signalling, where fire risks from fuel are high. Petrochemical plants benefit from optional hydrocarbon resistance, preventing sheath degradation.

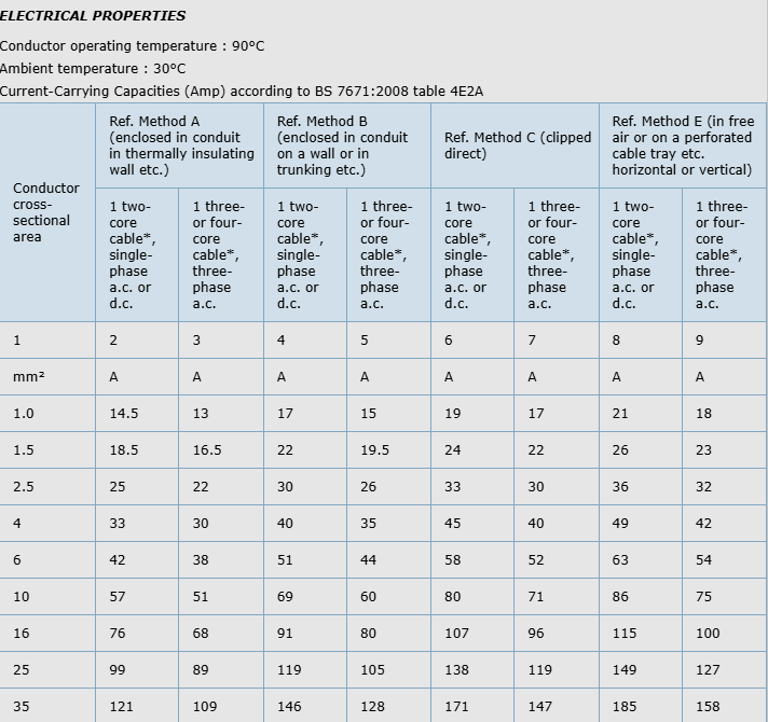

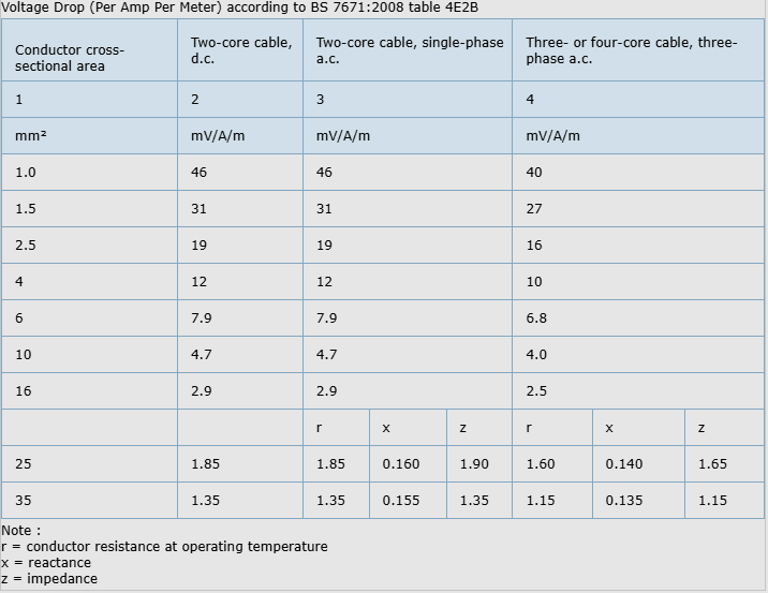

In South Africa, urban expansion in cities like Johannesburg and Cape Town has boosted demand for these in high-rises, complying with fire codes. Installation methods include clipping direct or enclosing in conduits, as per BS 7671 methods.

Recent South African Case Studies

Recent implementations underscore the cables' efficacy. In Eskom's power stations, Mica+XLPE insulated LSZH sheathed cables have been integrated to enhance fire safety. Eskom, facing frequent maintenance and upgrades amid load shedding, adopted these in stations like Medupi and Kusile post-2023, reducing fire propagation risks and ensuring operational continuity. This has minimised downtime, with reported 20% improvements in safety audits.

In Johannesburg's hospital projects, 2025 initiatives for electrical wiring in facilities like Charlotte Maxeke Johannesburg Academic Hospital incorporated LSZH cables for lighting and power distribution. These upgrades, part of post-COVID infrastructure enhancements, utilised 450/750V variants to meet enhanced fire resistance standards, facilitating safer environments for patients and staff.

At petrochemical sites, such as PetroSA's Mossel Bay refinery, LSZH cables were used in recent expansions for control systems, leveraging oil-resistant options to withstand harsh conditions. This 2024 project improved reliability, preventing incidents in flammable zones.

For airports, Airports Company South Africa (ACSA) at OR Tambo International incorporated these cables in terminal upgrades, complying with LSZH requirements for passenger safety. These cases demonstrate tangible benefits in risk mitigation and compliance.

Conclusion

450/750V XLPE insulated, LSZH sheathed power cables to BS 7211 represent a pinnacle of safety-focused engineering. Their adoption in South Africa not only aligns with global standards but addresses local challenges, paving the way for safer infrastructure. As development continues, these cables will remain integral to resilient electrical systems.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430