Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

450/750V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is TUV approved.

STANDARDS

Basic design to BS 7211:2012

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

450/750V

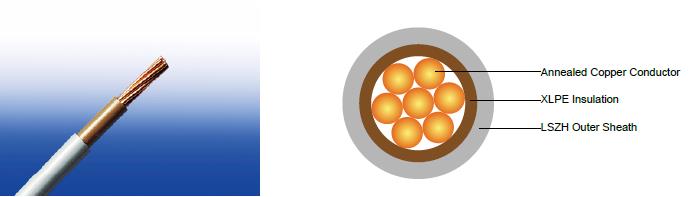

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, solid or stranded according to BS EN 60228 class 1 or class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. Crosslinked polyolefin material type EI 5 according to EN 50363-5 can be offered as option.

Outer Sheath : Extruded LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue.

Sheath Colour : White; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX300 07RZ1-U/R | |||||

|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Sheath Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | mm | kg/km |

1×1.0 | 1 | 0.7 | 0.8 | 3.9 | 4.8 | 26 |

1×1.5 | 1 | 0.7 | 0.8 | 4.2 | 5.0 | 34 |

1×2.5 | 1 | 0.7 | 0.8 | 4.6 | 5.5 | 46 |

1×4 | 1 | 0.7 | 0.8 | 5.2 | 6.3 | 65 |

1×6 | 1 | 0.7 | 0.8 | 5.7 | 6.8 | 90 |

1×1.0 | 2 | 0.7 | 0.8 | 4.0 | 4.9 | 31 |

1×1.5 | 2 | 0.7 | 0.8 | 4.3 | 5.2 | 39 |

1×2.5 | 2 | 0.7 | 0.8 | 4.7 | 5.6 | 51 |

1×4 | 2 | 0.7 | 0.9 | 5.3 | 6.4 | 72 |

1×6 | 2 | 0.7 | 0.9 | 5.9 | 7.1 | 99 |

1×10 | 2 | 0.7 | 0.9 | 6.7 | 8.1 | 141 |

1×16 | 2 | 0.7 | 0.9 | 7.6 | 9.2 | 205 |

1×25 | 2 | 0.9 | 1.0 | 9.4 | 11.4 | 318 |

1×35 | 2 | 0.9 | 1.1 | 10.6 | 12.8 | 482 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E1A

Conductor cross-sectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | Ref. Method F (in free air or on a perforated cable tray, horizontal or vertical etc) Touching | Ref. Method G (in free air) Spaced by one cable diameter | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

2 cables, single-phase a.c. or d.c. | 3 or 4 cables, three-phase a.c. | 2 cables, single-phase a.c. or d.c | 3 or 4 cables, three-phase a.c. | 2 cables, single-phase a.c. or d.c. flat and touching | 3 or 4 cables, three-phase a.c. flat and touching or trefoil | 2 cables, single-phase a.c. or d.c. flat | 3 cables, three-phase a.c. flat | 3 cables, three-phase a.c. trefoil | 2 cables, single-phase a.c. or d.c. or 3 cables three-phase a.c. flat | ||

Horizontal | Vertical | ||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

mm² | A | A | A | A | A | A | A | A | A | A | A |

1.0 | 14 | 13 | 17 | 15 | 19 | 17.5 | - | - | - | - | - |

1.5 | 19 | 17 | 23 | 20 | 25 | 23 | - | - | - | - | - |

2.5 | 26 | 23 | 31 | 28 | 34 | 31 | - | - | - | - | - |

4 | 35 | 31 | 42 | 37 | 46 | 41 | - | - | - | - | - |

6 | 45 | 40 | 54 | 48 | 59 | 54 | - | - | - | - | - |

10 | 61 | 54 | 75 | 66 | 81 | 74 | - | - | - | - | - |

16 | 81 | 73 | 100 | 88 | 109 | 99 | - | - | - | - | - |

25 | 106 | 95 | 133 | 117 | 143 | 130 | 161 | 141 | 135 | 182 | 161 |

35 | 131 | 117 | 164 | 144 | 176 | 161 | 200 | 176 | 169 | 226 | 201 |

In the realm of electrical engineering, the selection of appropriate power cables is paramount for ensuring safety, reliability, and efficiency in diverse infrastructure settings. The 450/750V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 (Single Core) represent a sophisticated solution designed for environments where fire hazards pose significant risks. These cables, featuring cross-linked polyethylene (XLPE) insulation and low smoke zero halogen (LSZH) sheathing, are engineered to minimise smoke emission and toxic gas release during combustion, making them ideal for densely populated or confined spaces.

Originating from standards set by the British Standards Institution (BSI), these cables adhere to BS 7211:2012, which outlines requirements for thermosetting insulated, non-armoured cables with low emission of smoke and corrosive gases. Their TUV approval further underscores their quality and compliance with international safety benchmarks. In South Africa, where rapid urbanisation and infrastructure development are underway, such cables play a crucial role in mitigating fire-related incidents, which have historically plagued high-density areas.

South Africa's electrical infrastructure faces unique challenges, including frequent power outages, cable theft, and the need for resilient systems in extreme climates. According to recent developments, South African researchers have pioneered non-destructive testing methods for XLPE insulated cables, enhancing maintenance practices and longevity. This innovation aligns with the cables' design, which prioritises durability and performance under stress.

Fire Performance Analysis

Fire performance is a cornerstone of these cables' design, particularly in applications where human life is at stake. The LSZH sheath, extruded from low-temperature smoke type LTS 4 material per BS 7655-6.1, ensures minimal smoke density and zero halogen content, preventing the release of hydrogen chloride gas that can corrode equipment and harm respiratory systems.

Analysing the test standards, the IEC 60332-1-2 flame retardance test involves exposing a single cable to a 1 kW flame for 60 seconds, with self-extinguishment required within specified limits. For bundled configurations, IEC 60332-3-24 simulates vertical propagation, limiting char length to 2.5 metres. These tests demonstrate the cables' ability to contain fire spread, crucial in enclosed spaces like tunnels or high-rises.

Halogen-free testing under IEC 60754-1 measures hydrogen halide content below 0.5%, while acidity tests (IEC 60754-2) ensure pH above 4.3 and conductivity below 10 μS/mm, minimising corrosion. Smoke density tests in a 3m cube chamber limit transmittance to above 60%, aiding visibility for evacuation.

In South African contexts, these features are vital amid rising fire incidents in urban areas. A 2023 study on structural fire hazards highlighted gaps in developing countries, including South Africa, where inadequate fire safety leads to higher casualties. The IRIS-Fire project (2020-2025), funded by UKRI, developed models for fire risks in informal settlements but underscores the need for advanced cables in formal infrastructure. Comparatively, XLPE insulation outperforms PVC in thermal stability, maintaining integrity up to 90°C continuously and 250°C during short circuits, reducing fire ignition risks.

This rigorous fire performance positions these cables as a proactive measure against disasters, aligning with global trends towards safer building materials.

Usage Scenarios and South African Case Studies

Primarily used in power stations, mass transit systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings, these cables excel where fire safety is non-negotiable.

In South Africa, the Gautrain rapid rail link exemplifies mass transit application. Since its inception, Gautrain stations mandate LSZH armoured cables for fire safety in public spaces, as per regulations. A 2020-2025 review of construction management highlighted integrated systems ensuring passenger safety in underground tunnels, where LSZH properties prevent smoke accumulation.

At OR Tambo International Airport, ACSA's R21.7 billion infrastructure upgrade programme (announced 2025) includes fire safety systems and power backups. This multi-year project, encompassing terminal expansions and energy resilience, likely deploys XLPE LSZH cables to handle high passenger volumes and comply with aviation safety standards, reducing risks in confined terminals.

In healthcare, Chris Hani Baragwanath Hospital faced cable theft disruptions in 2022, affecting oxygen and cooling systems. Subsequent upgrades emphasised secure, fire-resistant cabling, with XLPE LSZH variants ensuring uninterrupted power in critical wards, as noted in 2023 security reports.

For high-rises, Johannesburg's evolving skyline demands fire-safe solutions. A 2023 analysis of high-rise fire challenges advocated LSZH cables to address evacuation issues. The Menlyn Maine precinct, completed in phases up to 2025, incorporated such cables in electrical reticulation, enhancing sustainability and safety in mixed-use towers.

Renewable energy projects, like Nepoworx's school installations in Orlando eKhaya and Power Park (2025), utilise XLPE cables for durable connections. These cases demonstrate the cables' versatility in South Africa's push towards net-zero infrastructure.

Conclusion

The 450/750V XLPE Insulated, LSZH Sheathed Power Cables to BS 7211 embody advanced engineering for safety-critical applications. Their in-depth specifications and South African implementations underscore their value in fostering resilient infrastructure. As the nation advances, adopting these cables will mitigate risks and support sustainable growth.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430