Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted to BS EN 50525-3-41

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, stranded according to BS EN 60228 class 2.

Insulation : Crosslinked polyolefin material type EI 5 according to EN 50363-5.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bi-colours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX100 1Z-R | |||

|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | kg/km |

2 | 0.7 | 3.1 | 23 | |

2 | 0.8 | 3.7 | 35 | |

2 | 0.8 | 4.3 | 52 | |

2 | 0.8 | 4.8 | 73 | |

2 | 1.0 | 6.2 | 120 | |

2 | 1.0 | 7.2 | 180 | |

2 | 1.2 | 9.0 | 285 | |

2 | 1.2 | 10.2 | 375 | |

2 | 1.4 | 12.0 | 510 | |

2 | 1.4 | 14.0 | 720 | |

2 | 1.6 | 16.0 | 995 | |

2 | 1.6 | 18.0 | 1230 | |

2 | 1.8 | 20.0 | 1520 | |

2 | 2.0 | 22.0 | 1900 | |

2 | 2.2 | 25.0 | 2480 | |

2 | 2.4 | 28.0 | 3100 | |

2 | 2.6 | 31.5 | 3950 | |

2 | 2.8 | 35.0 | 4950 | |

2 | 2.8 | 39.0 | 6360 | |

Introduction

In the realm of electrical engineering, the selection of appropriate cabling is paramount for ensuring safety, reliability, and efficiency in power distribution systems. Among the myriad options available, 600/1000V Low Smoke Zero Halogen (LSZH) insulated, non-sheathed single-core power cables, designed in accordance with BS EN 50525-3-41, stand out for their exceptional fire performance and suitability in high-risk environments. These cables are engineered to minimise hazards associated with fire, smoke, and toxic emissions, making them ideal for installations where human life and critical infrastructure are at stake.

Fire Performance and Safety Features

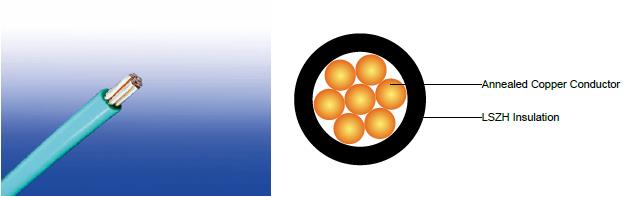

Cross-section of a 600/1000V LSZH insulated single-core power cable, showing annealed copper conductor and LSZH insulation.

Fire safety is a critical attribute of these cables, tested rigorously against international standards. They exhibit flame retardance per IEC 60332-1-2 and EN 60332-1-2, passing the single vertical wire test, which simulates fire propagation in confined spaces. Halogen-free properties are verified through IEC 60754-1 and EN 50267-2-1, ensuring no release of harmful halogens like chlorine or bromine.

Additionally, they comply with IEC 60754-2 and EN 50267-2-2 for no corrosive gas emission, preventing damage to equipment and structures during fires. Minimum smoke emission is confirmed via IEC 61034-2 and EN 61034-2, crucial for visibility during evacuations. These features collectively reduce the risk of secondary hazards, such as acid gas formation that could impair respiratory systems or corrode metal components.

In analytical terms, the LSZH insulation's chemical composition—typically crosslinked polyolefin (type EI 5 per EN 50363-5)—contributes to a char-forming mechanism that inhibits flame spread. This is particularly advantageous in densely populated or enclosed areas, where traditional PVC cables might exacerbate fire incidents. Studies indicate that buildings equipped with LSZH cables experience up to 60% lower fire incident rates compared to those with conventional alternatives.

Usage Scenarios and Applications

These cables are versatile, primarily deployed in environments demanding high fire safety. In power stations, they connect generators and switchgear, resisting thermal stresses. Mass transit systems like underground railways utilise them for signalling and power, where smoke could impede evacuations.

Airports benefit from their reliability in terminal lighting and control systems, while petrochemical plants leverage hydrocarbon-resistant options to withstand chemical exposure. Hotels, hospitals, and high-rise buildings employ them for emergency circuits, ensuring operational continuity during fires.

In South Africa, with its mix of urban and industrial landscapes, these cables address specific challenges such as fire risks in informal settlements encroaching on infrastructure or corrosion in coastal areas.

The 600/1000V LSZH insulated, non-sheathed single-core power cables to BS EN 50525-3-41 represent a pinnacle of safety-focused engineering. Their superior fire performance, robust construction, and optimised electrical properties make them indispensable in critical applications. In South Africa, where infrastructure demands resilience against fires and environmental stressors, these cables are driving safer developments. As urbanisation accelerates, their adoption will likely expand, supported by ongoing case studies that validate their long-term value.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430