Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS EN 50525-3-31

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor : Copper conductor according to BS EN 60228 class 2.

Fire Barrier : Mica glass tape.

Insulation : Thermoplastic compound of type TI 7 to EN 50363-7.

Insulation Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 70°C

Maximum short circuit temperature (5 Seconds) : 160°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX100 1mZ1-R | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

2 | 0.7 | 3.7 | 4.3 | 28 | |

2 | 0.8 | 4.3 | 5.0 | 42 | |

2 | 0.8 | 4.8 | 5.6 | 59 | |

2 | 0.8 | 5.3 | 6.2 | 81 | |

2 | 1.0 | 6.6 | 7.7 | 133 | |

2 | 1.0 | 7.4 | 8.8 | 197 | |

2 | 1.2 | 9.1 | 10.7 | 308 | |

2 | 1.2 | 10.0 | 11.9 | 412 | |

2 | 1.4 | 11.6 | 13.8 | 558 | |

2 | 1.4 | 13.1 | 15.6 | 782 | |

2 | 1.6 | 15.1 | 18.1 | 1078 | |

2 | 1.6 | 16.6 | 19.8 | 1342 | |

2 | 1.8 | 18.3 | 21.9 | 1650 | |

2 | 2.0 | 20.3 | 24.3 | 2067 | |

2 | 2.2 | 23 | 27.6 | 2703 | |

2 | 2.4 | 25.5 | 30.6 | 3378 | |

2 | 2.6 | 28.5 | 34.2 | 4267 | |

2 | 2.8 | 31.5 | 37.9 | 5359 | |

2 | 2.8 | 35 | 42.1 | 6884 | |

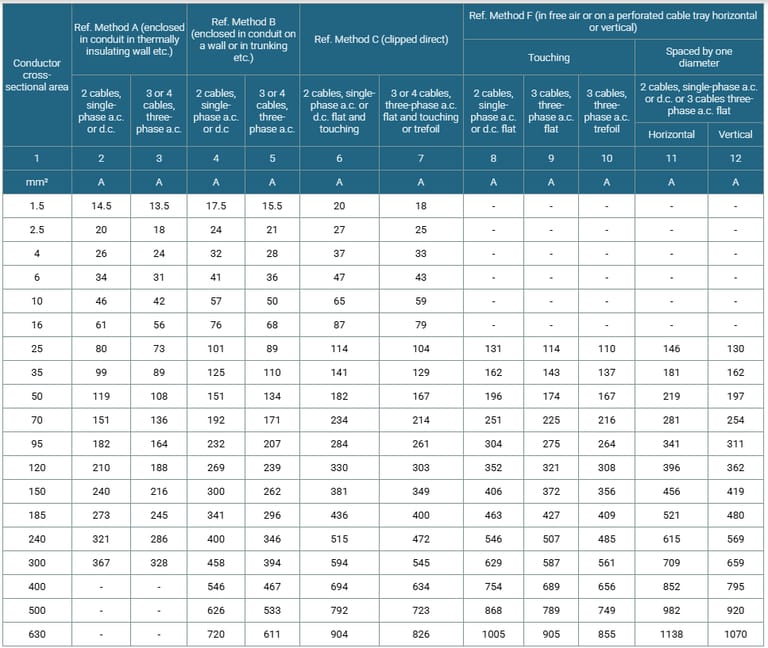

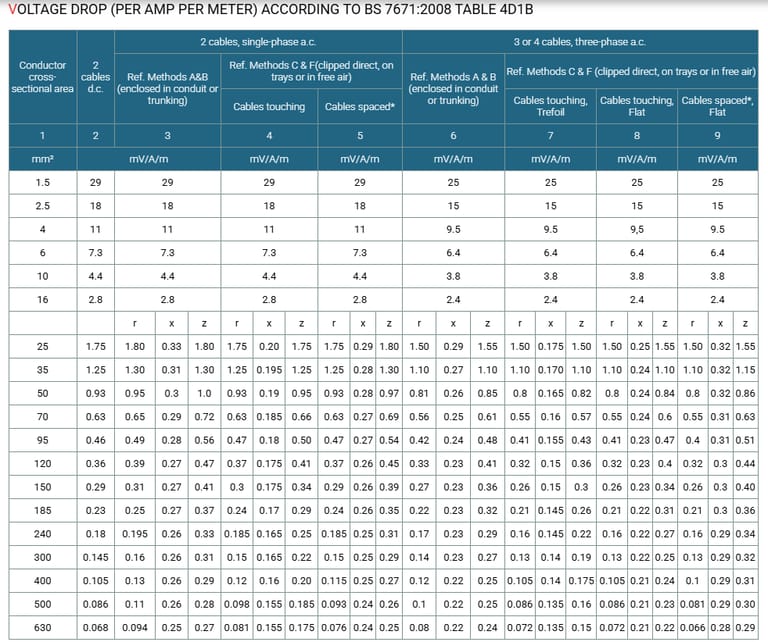

ELECTRICAL PROPERTIES

Conductor operating temperature: 70°C

Ambient temperature: 30°C

In the realm of electrical engineering and infrastructure development, the selection of appropriate power cables is paramount to ensuring safety, reliability, and compliance with stringent regulations. Among the specialised options available, 600/1000V Mica+LSZH insulated, non-sheathed power cables to BS EN 50525-3-31 (single core), often designated as FFX100 1mZ1-R, stand out for their exceptional fire-resistant properties and suitability for high-risk environments. These cables are engineered to maintain circuit integrity during fire events, minimising risks associated with smoke emission, corrosive gases, and flame propagation. In South Africa, where urbanisation and industrial growth have amplified the demand for robust electrical systems, these cables play a critical role in safeguarding lives and assets.

South Africa's diverse infrastructure landscape, encompassing bustling metropolitan areas like Johannesburg and Cape Town, demands cables that can withstand extreme conditions. The country's history of fire incidents in public facilities underscores the need for advanced materials like low smoke zero halogen (LSZH) insulation combined with mica glass tape barriers. LSZH compounds, free from halogens, reduce the release of toxic fumes during combustion, which is vital in confined spaces such as underground mass transit systems or high-rise buildings. Mica, a naturally occurring mineral with high thermal stability, enhances the cable's ability to endure prolonged exposure to flames without compromising conductivity.

Applications and Usage Scenarios

Primarily deployed in power stations for feeder circuits, these cables maintain integrity during fires, preventing blackouts. In mass transit like Johannesburg's Rea Vaya, they power signalling and lighting. Airports benefit from their low-smoke properties, aiding safe evacuations. Petrochemical plants in Secunda use hydrocarbon-resistant variants. Hotels, hospitals, and high-rises in Durban leverage their halogen-free nature for occupant safety.

In South Africa, urban expansion drives adoption; for example, in Cape Town's mixed-use developments, they integrate with smart grids for reliable power.

South African Case

Authentic case studies underscore the cables' impact. The 2021 fire at Charlotte Maxeke Johannesburg Academic Hospital (CMJAH) highlighted deficiencies in fire safety systems. The blaze, originating in a storage area, spread via electrical conduits, disrupting operations for months. Post-incident reviews revealed outdated PVC cables contributed to smoke obscuration and toxicity, complicating evacuations. In response, upgrades incorporated Mica+LSZH cables for emergency circuits, ensuring circuit integrity per BS 6387. This retrofit, completed by 2023, involved installing 1×95 mm² cables in critical wards, reducing smoke emission risks. Lessons from CMJAH influenced provincial guidelines, emphasising LSZH in public health facilities.

At Cape Town International Airport (CTIA), a 2019-2022 refurbishment programme addressed fire risks in terminal expansions. With passenger volumes exceeding 10 million annually, safety is paramount. The project utilised 600/1000V Mica+LSZH cables for runway lighting and backup power, compliant with ACSA standards. In substations, 1×240 mm² variants were clipped direct (Method C), carrying up to 515 A while maintaining integrity under IEC 60331. This enhanced resilience against electrical faults, drawing from global benchmarks like Paphos Airport but adapted for South African conditions.

In power stations, Medupi Power Station in Limpopo integrated LSZH cables during Phase 2 commissioning (2015-2020). Facing coal dust and heat, 1×400 mm² cables were used for auxiliary systems, supporting 720 A in trunking. Their fire propagation resistance prevented escalation in simulated fire tests, aligning with Eskom's safety protocols.

These cases demonstrate tangible benefits: reduced downtime, enhanced safety, and regulatory compliance, fostering broader adoption.

Conclusion

The 600/1000V Mica+LSZH insulated power cables represent a pinnacle of fire-safe engineering, vital for South Africa's infrastructure. Their standards-compliant design, robust construction, and superior performance ensure reliability in demanding scenarios. As evidenced by case studies, they mitigate risks effectively, paving the way for safer developments. Future innovations may include smart monitoring, but their current form already sets a benchmark for excellence.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430