Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-41 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from BS EN 50525-3-41

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; BS 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Halogen free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

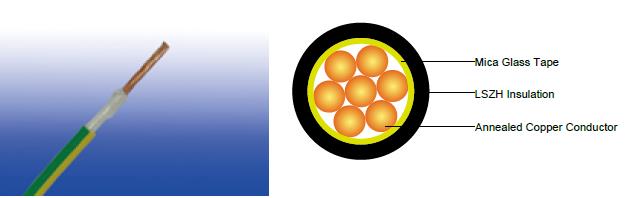

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, stranded according to BS EN 60228 class 2.

Fire Barrier : Mica glass tape.

Insulation : Crosslinked polyolefin material type EI 5 according to EN 50363-5.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bi-colours of any combination of the above mono-colours are permitted.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

OD<8mm : 4 × Overall Diameter

8mm≤OD≤12mm : 5 × Overall Diameter

OD>12mm : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX100 1mZ-R | |||

|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | kg/km |

2 | 0.7 | 4.1 | 27 | |

2 | 0.8 | 4.7 | 39 | |

2 | 0.8 | 5.3 | 57 | |

2 | 0.8 | 5.8 | 78 | |

2 | 1.0 | 7.2 | 125 | |

2 | 1.0 | 8.2 | 186 | |

2 | 1.2 | 10.0 | 291 | |

2 | 1.2 | 11.2 | 382 | |

2 | 1.4 | 13.0 | 517 | |

2 | 1.4 | 15.0 | 728 | |

2 | 1.6 | 17.0 | 1003 | |

2 | 1.6 | 19.0 | 1239 | |

2 | 1.8 | 21.0 | 1529 | |

2 | 2.0 | 23.0 | 1910 | |

2 | 2.2 | 26.0 | 2492 | |

2 | 2.4 | 29.0 | 3113 | |

2 | 2.6 | 32.5 | 3964 | |

2 | 2.8 | 36.0 | 4965 | |

2 | 2.8 | 40.0 | 6376 | |

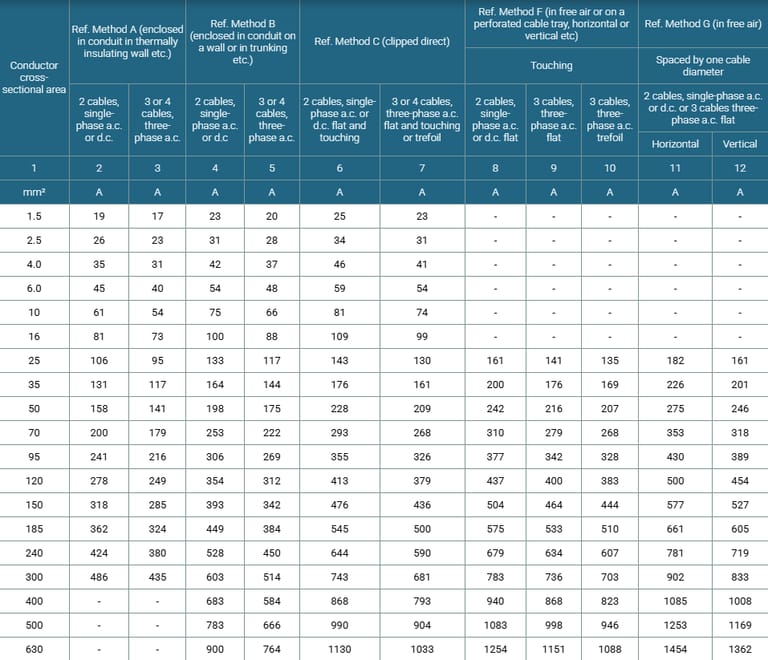

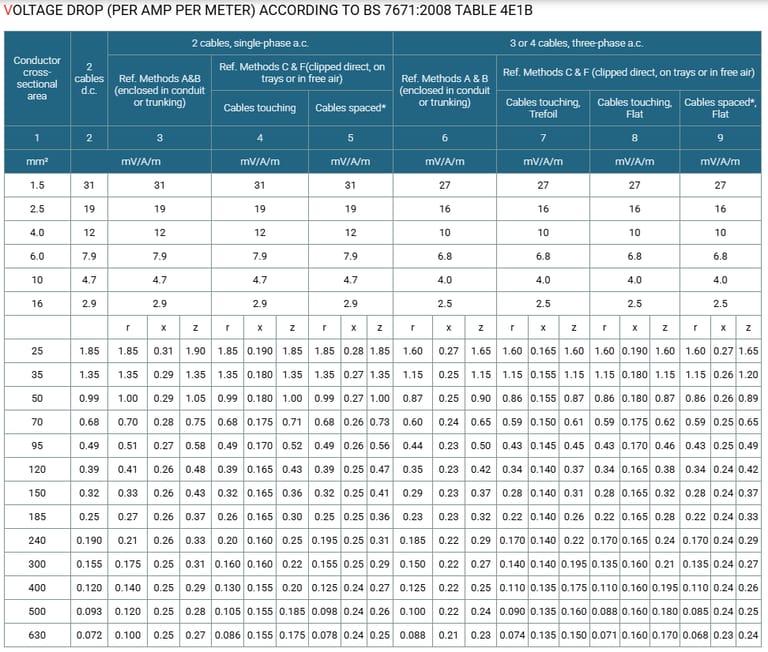

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Introduction

In the bustling landscape of South Africa, where rapid urbanisation meets the demands of industrial growth, the integrity of electrical infrastructure stands as a cornerstone of safety and continuity. From the humming generators of Eskom's power stations to the life-support systems in Johannesburg's overcrowded hospitals, and the towering silhouettes of Cape Town's high-rise developments, electrical cables form the invisible veins that pulse with power. Yet, these conduits are not impervious to the ravages of fire—a peril exacerbated by cable theft, vandalism, and the inherent flammability of conventional wiring. Enter the 600/1000V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core), a pinnacle of fire-resistant engineering designed to maintain circuit integrity amid infernos, ensuring that critical systems remain operational when every second counts.

These single-core cables, often branded under designations like FFX100 1mZ-R, represent a sophisticated fusion of materials science and electrical engineering. Compliant with the rigorous BS EN 50525-3-31 standard, they are tailored for low-voltage applications in environments where fire poses an existential threat. The "Mica+LSZH" nomenclature—denoting mica glass tape as a fire barrier and low smoke zero halogen (LSZH) crosslinked polyolefin insulation—encapsulates their core innovation: resilience without compromise. In a nation grappling with frequent electrical fires, as evidenced by the 2023 Marshalltown blaze that claimed 76 lives in a hijacked Johannesburg building due to illegal cable connections, such cables are not merely components; they are lifelines.

Applications

These cables thrive in high-stakes realms: power stations for generator feeds, mass transit (e.g., Gautrain tunnels) for signalling, airports like OR Tambo for runway lighting, petrochemicals for pump motors, hotels for emergency lifts, hospitals for ICU backups, and high-rises for riser shafts.

In power stations, single-core configs suit busbar connections, enduring 250°C faults without arc flash escalation. Hospitals deploy them for non-sheathed flexibility in conduit-embedded walls, ensuring ventilator circuits persist 90 minutes post-fire alarm. High-rises leverage LSZH for atria, complying with SANS 10400-X (lift shafts).

Scenarios include: fault-tolerant paralleling in Eskom grids, rodent-proof sheaths in Cape Town hotels, UV-stabilised runs in Johannesburg airports. Installation mandates: torque to 2 Nm for lugs, derate 20% for grouping >4 cables.

The 600/1000V Mica+LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core) embody a technological bulwark against South Africa's fire vulnerabilities. From their layered construction to unyielding standards, these cables deliver unmatched safety in critical applications. Case studies from Koeberg, Gauteng hospitals, and Joburg high-rises underscore their transformative potential, urging policymakers and engineers to prioritise adoption. In a nation rebuilding amid adversity, investing in such innovations is not optional—it's imperative for a safer tomorrow.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430