Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

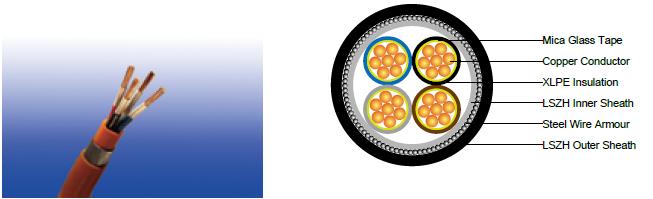

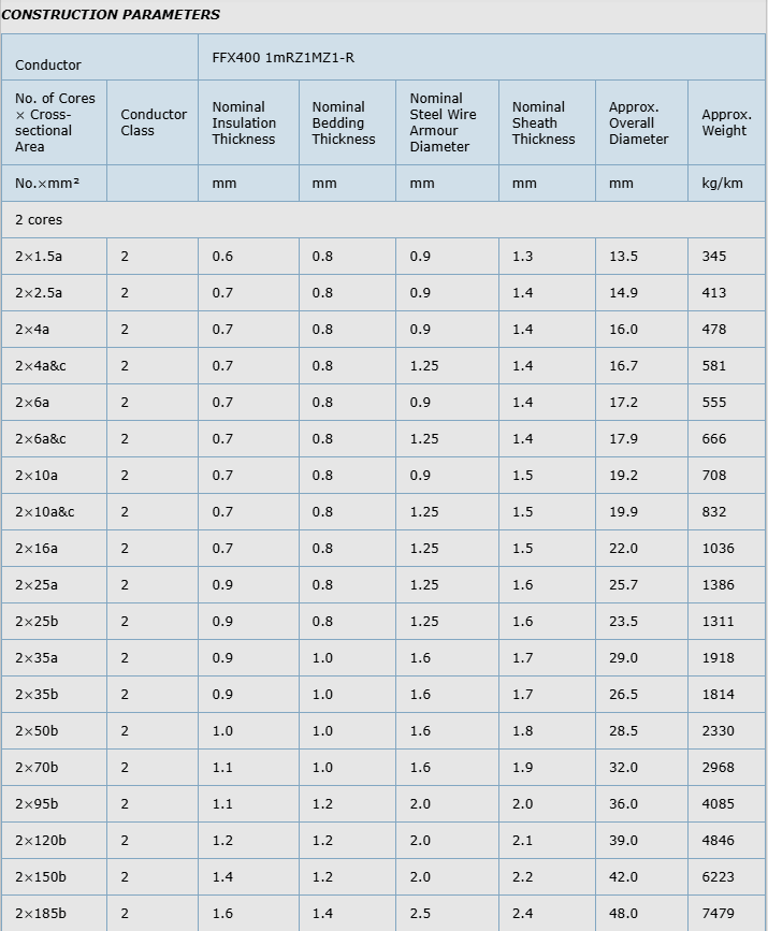

600/1000V Mica+XLPE Insulated, LSZH Sheathed, Armoured Power Cables to BS 7846 (2-5 Cores & Multicore)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to BS 7846

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; EN 6387; BS 8491 |

Flame Retardance (single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas emission | IEC 60754-2; EN 50267-2-2 |

Minimum smoke emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor : Annealed copper wire, stranded according to BS EN 60228 class 2.

Fire Barrier : Mica glass tape.

Insulation : XLPE type GP 8 according to BS 7655-1.3. HEPR type GP 6 according to BS 7655-1.2 or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Bedding : Extruded layer of polymeric material.

Armouring : Galvanized steel wire.

Outer Sheath : Extruded layer of polymeric material LTS 1 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour

2-core : Brown and blue.

3-core : Brown, black and grey.

4-core : Blue, brown, black and grey.

5-core : Green-and-yellow, blue, brown, black, grey.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 8 x Overall Diameter

Introduction

In an era where fire safety is paramount, especially in densely populated urban environments, the role of specialised electrical cables cannot be overstated. The 600/1000V Mica+XLPE insulated, LSZH sheathed, armoured power cables, designed to comply with British Standard BS 7846, represent a pinnacle of engineering innovation in fire-resistant technology. These cables are engineered to maintain circuit integrity during fire events, ensuring that essential systems like emergency lighting, fire alarms, and evacuation mechanisms continue to function. This is particularly crucial in high-risk settings where human lives and critical infrastructure are at stake.

South Africa, with its rapid urbanisation and industrial growth, has seen a surge in the adoption of such cables. The country's diverse landscape, from bustling metropolises like Johannesburg and Cape Town to expansive mining operations, demands robust electrical solutions that align with stringent safety regulations. According to recent market analyses, the demand for fire-resistant cables in South Africa is driven by regulatory compliance with standards like SANS 10400 Part T, which emphasises fire protection in buildings. This article delves into the technical intricacies of these BS 7846-compliant cables, exploring their construction, specifications, and real-world applications. By examining recent case studies from South African projects, we highlight how these cables contribute to enhanced safety and operational resilience.

The BS 7846 standard, which these cables adhere to, sets rigorous requirements for armoured cables that provide enhanced fire resistance. Unlike conventional cables, these incorporate mica tape for thermal barriers and low smoke zero halogen (LSZH) sheathing to minimise toxic emissions during combustion. This combination not only preserves electrical functionality but also reduces secondary hazards like smoke inhalation, which accounts for a significant portion of fire-related fatalities. In South Africa, where fire incidents in high-rise buildings and public facilities have prompted stricter enforcement of safety codes, these cables are increasingly integral to new constructions and retrofits.

As urban densification accelerates, with projections indicating that South Africa's urban population will exceed 70% by 2030, the need for reliable fire safety measures intensifies. This analysis will provide a comprehensive overview, from the cables' material composition to their performance under extreme conditions, underscoring their importance in safeguarding lives and property.

Usage Scenarios and Applications

These cables are primarily deployed in environments requiring uninterrupted power during emergencies, such as power stations for auxiliary systems, mass transit underground passenger systems for signalling, and airports for runway lighting and control towers. In petrochemical plants, their hydrocarbon-resistant options protect against chemical exposure, while in hotels, hospitals, and high-rise buildings, they power fire pumps, lifts, and ventilation.

In high-rise structures, the cables' armour prevents damage from falling debris, and their fire resistance ensures evacuation routes remain illuminated. Multicore variants (up to 37 cores) suit complex control systems in hospitals, maintaining life-support equipment. Optional anti-termite features are beneficial in rural or mining installations.

South Africa's mining sector utilises these for underground power distribution, where fire risks from methane are high. Overall, their versatility supports sustainable infrastructure development.

The 600/1000V Mica+XLPE insulated, LSZH sheathed, armoured power cables to BS 7846 exemplify cutting-edge fire safety technology. Their specifications and applications, validated through South African case studies, underscore their indispensable value in protecting lives and infrastructure. As South Africa advances, continued adoption will fortify resilience against fire hazards.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430