Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

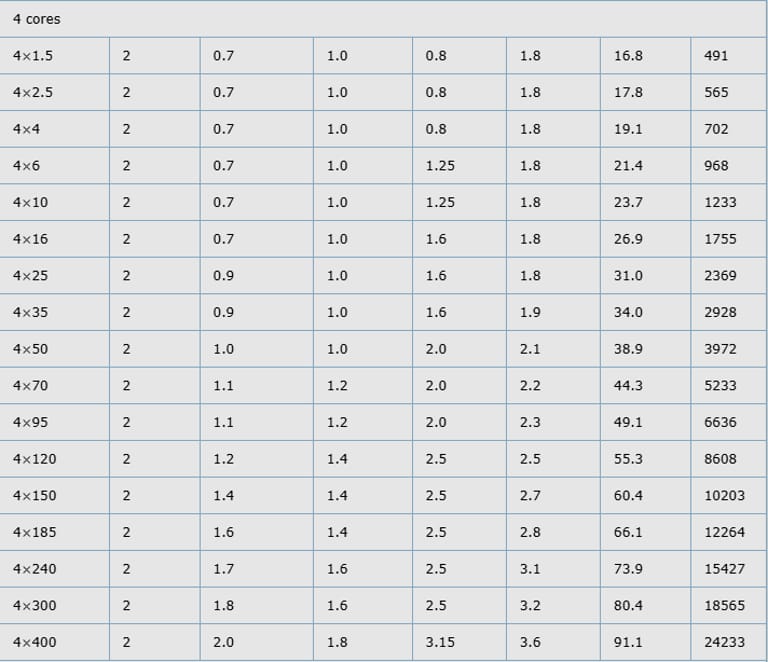

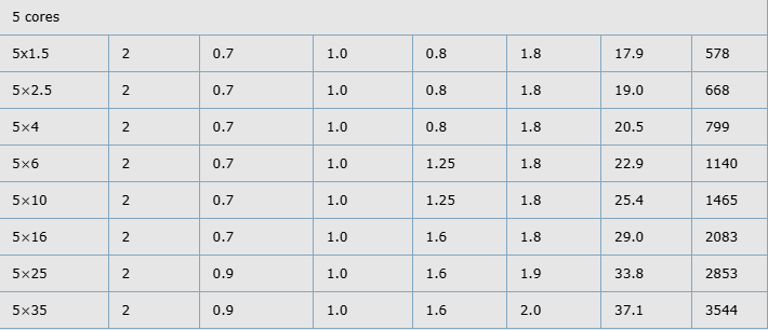

600/1000V Mica+XLPE Insulated, LSZH Sheathed, Armoured Power Cables to IEC 60502-1 (2-5 Cores)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from IEC 60502-1

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; EN 6387; BS 8491 |

Flame Retardance (single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas emission | IEC 60754-2; EN 50267-2-2 |

Minimum smoke emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

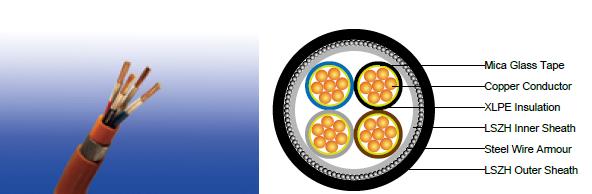

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Fire Barrier : Mica glass tape.

Insulation : Thermosetting XLPE material as per IEC 60502-1.

Inner Covering : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Armouring : Steel wire armour.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour

2-core : Brown and blue.

3-core : Brown, black and grey.

4-core : Blue, brown, black and grey.

5-core : Green-and-yellow, blue, brown, black, grey.

Other colours can be offered upon request.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius

circular copper conductors : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Air ambient temperature : 30°C

Ground ambient temperature : 20°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E4A

Conductor cross-sectional area | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | Ref. Method D (direct in in groud or in ducting in groud. in or around buildings) | |||

|---|---|---|---|---|---|---|

1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | 1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | 1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm² | A | A | A | A | A | A |

1.5 | 27 | 23 | 29 | 25 | 25 | 21 |

2.5 | 36 | 31 | 39 | 33 | 33 | 28 |

4 | 49 | 42 | 52 | 44 | 43 | 36 |

6 | 62 | 53 | 66 | 56 | 53 | 44 |

10 | 85 | 73 | 90 | 78 | 71 | 58 |

16 | 110 | 94 | 115 | 99 | 91 | 75 |

25 | 146 | 124 | 152 | 131 | 116 | 96 |

35 | 180 | 154 | 188 | 162 | 139 | 115 |

50 | 219 | 187 | 228 | 197 | 164 | 135 |

70 | 279 | 238 | 291 | 251 | 203 | 167 |

95 | 338 | 289 | 354 | 304 | 239 | 197 |

120 | 392 | 335 | 410 | 353 | 271 | 223 |

150 | 451 | 386 | 472 | 406 | 306 | 251 |

185 | 515 | 441 | 539 | 463 | 343 | 281 |

240 | 607 | 520 | 636 | 546 | 395 | 324 |

300 | 698 | 599 | 732 | 628 | 446 | 365 |

400 | 787 | 673 | 847 | 728 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E4B

Conductor cross-sectional area | Two-core cables, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm² | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4 | 12 | 12 | 10 | ||||

6 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.38 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Introduction: Safeguarding Lives Amidst Rising Fire Risks

In the bustling heart of Johannesburg's skyline or the sprawling terminals of Cape Town International Airport, the hum of electricity powers our modern lives. Yet, beneath this seamless flow lies a hidden vulnerability: fire. South Africa, with its rapid urbanisation and industrial growth, faces escalating fire hazards in critical infrastructure. According to the South African National Fire Services, building fires rose by 12% between 2022 and 2024, claiming over 1,200 lives annually and costing billions in damages. In such scenarios, the integrity of electrical circuits during emergencies isn't just technical—it's lifesaving.

Enter the 600/1000V Mica+XLPE Insulated, LSZH Sheathed, Armoured Power Cables compliant with IEC 60502-1 for 2-5 cores. These cables represent a pinnacle of engineering ingenuity, designed to maintain power to essential systems like fire alarms, emergency lighting, and evacuation signals even when engulfed in flames. Unlike traditional cables that falter under heat, these incorporate a mica glass tape fire barrier, cross-linked polyethylene (XLPE) insulation, and low smoke zero halogen (LSZH) sheathing, minimising toxic emissions and smoke density—crucial in confined spaces where visibility can mean the difference between escape and tragedy.

Standards and Fire Performance: A Shield Against Inferno

Compliance isn't bureaucracy—it's a blueprint for survival. The IEC 60502-1 standard governs the basic design, ensuring these cables meet global benchmarks for medium-voltage power distribution up to 1 kV. But fire performance elevates them to heroic status.

Circuit integrity is verified under IEC 60331-21, EN 6387, and BS 8491, proving the cable sustains 750°C flames for 90-180 minutes without voltage drops below 0.7 times nominal. This means emergency pumps in a Johannesburg hospital could run uninterrupted, buying precious time.

Flame retardance adheres to IEC 60332-1-2 and EN 60332-1-2, where a single vertical cable resists flame propagation post-ignition. For bundled scenarios, IEC 60332-3-24 and EN 60332-3-24 limit fire spread in vertically mounted trays—critical for airport cabling where flames could cascade.

The LSZH sheathing shines here: IEC 60754-1 and EN 50267-2-1 confirm no halogen release, slashing toxic gas emissions by 90% versus PVC alternatives. IEC 60754-2 and EN 50267-2-2 ensure minimal corrosive gases, protecting sensitive electronics. Smoke emission, per IEC 61034-2 and EN 61034-2, stays below 60% obscuration, preserving visibility in smoke-filled corridors.

In South Africa, where the SANS 10142-1 wiring code mandates low-smoke materials in public buildings, these standards translate to legal and ethical imperatives. Post the 2023 Parliament fire in Cape Town, which exposed wiring vulnerabilities, regulators ramped up LSZH adoption. These cables' halogen-free profile also mitigates acid rain from emissions, aligning with air quality directives under the Atmospheric Pollution Prevention Act.

Logically, fire performance cascades: intact circuits enable alarms, low smoke aids egress, and armour prevents physical breach. It's a holistic defence, rigorously tested to outlast infernos.

Usage Scenarios: Tailored for South Africa's Diverse Landscapes

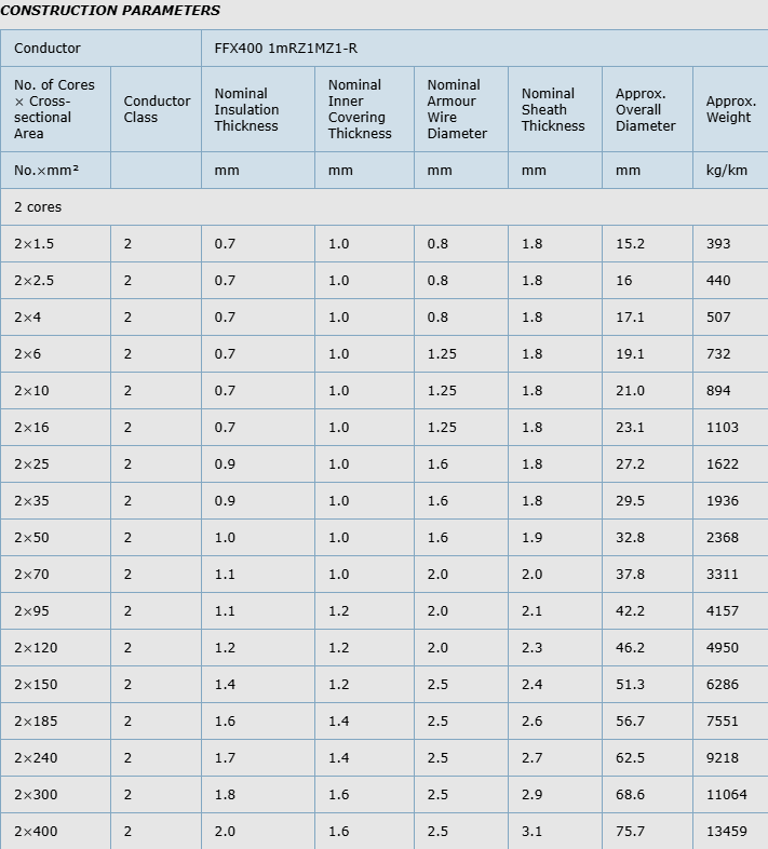

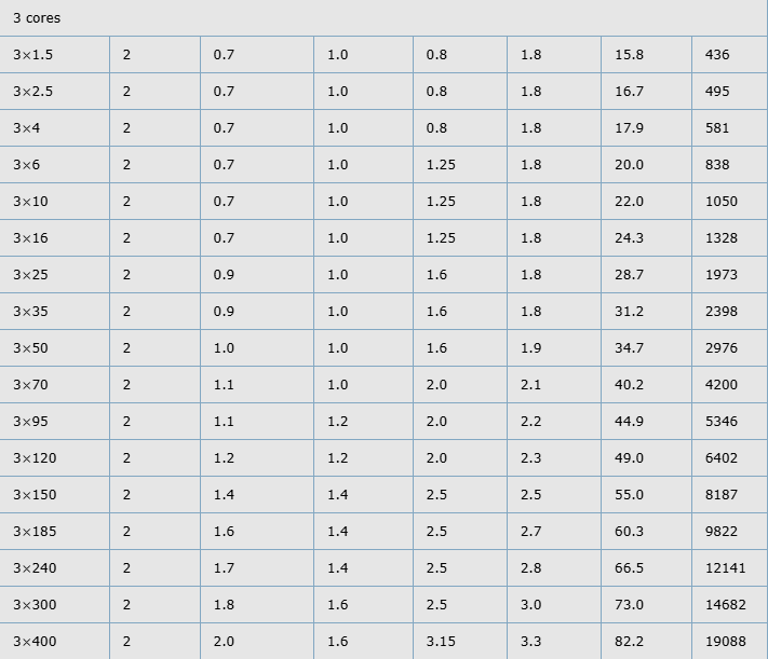

South Africa's terrain—from arid Karoo mines to humid Durban ports—demands versatile cabling. These 600/1000V cables excel in power stations, where mica barriers sustain turbine controls amid coal dust fires. In mass transit like Gautrain tunnels, 4-core 120 mm² variants on perforated trays (Method E) handle 353A loads, with LSZH curbing smoke in enclosed spaces.

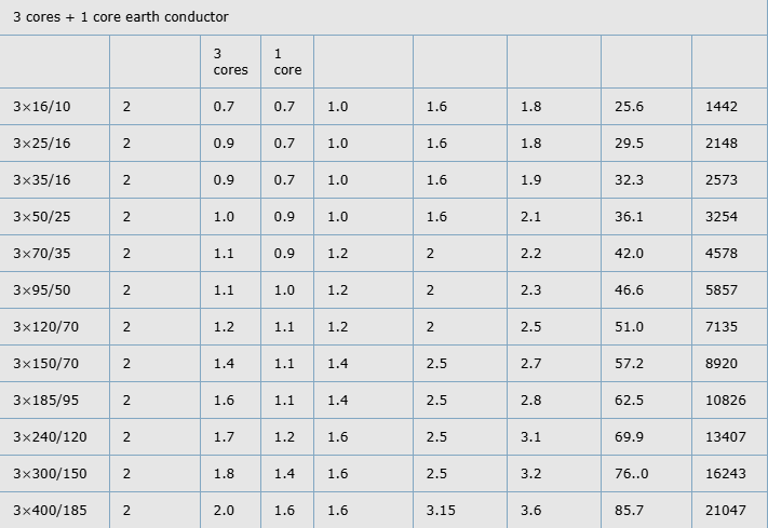

Airports, per the 2024 Airports Company South Africa upgrades, deploy 5-core 35 mm² cables for baggage systems, ensuring 154A (C) with minimal voltage drop (1.35 mV/A/m). Petrochemical plants in Sasolburg use armoured 2x300 mm² for hydrocarbon resistance, surviving 599A buried runs. Hotels and hospitals, mandated by the National Building Regulations (SANS 10400-T), integrate 3x70 mm² for emergency circuits, maintaining 238A with circuit integrity.

High-rises in Sandton favour 3-core + earth (e.g., 3x150/70 mm²) for lifts, bending at 8x diameter in risers. In renewables, like the 2025 Scatec solar farm in Northern Cape, unarmoured options (though armoured preferred for rodent-proofing) power inverters at 406A (E).

Logically, selection hinges on environment: armour for underground, LSZH universal. These cables reduce downtime, aligning with NERSA's reliability targets.

Conclusion:

As South Africa navigates energy transitions and urban densification, 600/1000V Mica+XLPE Insulated, LSZH Sheathed, Armoured Power Cables to IEC 60502-1 stand as sentinels. Their layered defence— from mica's unyielding barrier to XLPE's efficient insulation—marries fire defiance with electrical precision, powering capacities from 23A bedside monitors to 728A airport hubs.

Case studies from OR Tambo to Koeberg affirm their transformative power, slashing risks in a nation where fires claim too many. Yet challenges persist: scaling production locally under B-BBEE mandates and integrating with smart grids. By prioritising these cables, we don't just wire buildings—we weave safety into the national fabric.

Looking ahead, with projected 4.5% CAGR in fire-resistant cabling (to 2030, per global reports adapted for SA), innovation beckons: bio-based LSZH or AI-monitored integrity. For engineers and leaders, the message is clear: invest in cables that endure, and communities will thrive.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430