Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

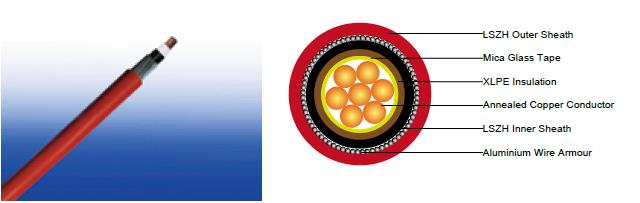

600/1000V Mica+XLPE Insulated, LSZH Sheathed, Armoured Power Cables to IEC 60502-1 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design adapted from IEC 60502-1

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; EN 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas emission | IEC 60754-2; EN 50267-2-2 |

Minimum smoke emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

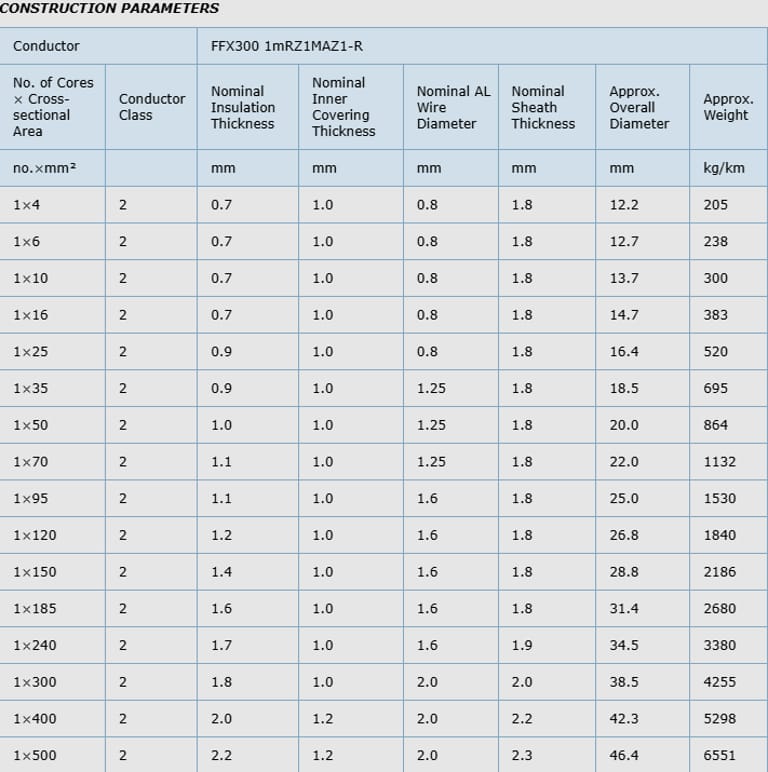

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Fire Barrier : Mica glass tape.

Insulation : Thermosetting XLPE material and thickness shall be as per IEC 60502-1.

Inner Covering Option : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Armouring : Aluminium wire.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue; other colours can be offered upon request.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 6 × Overall Diameter

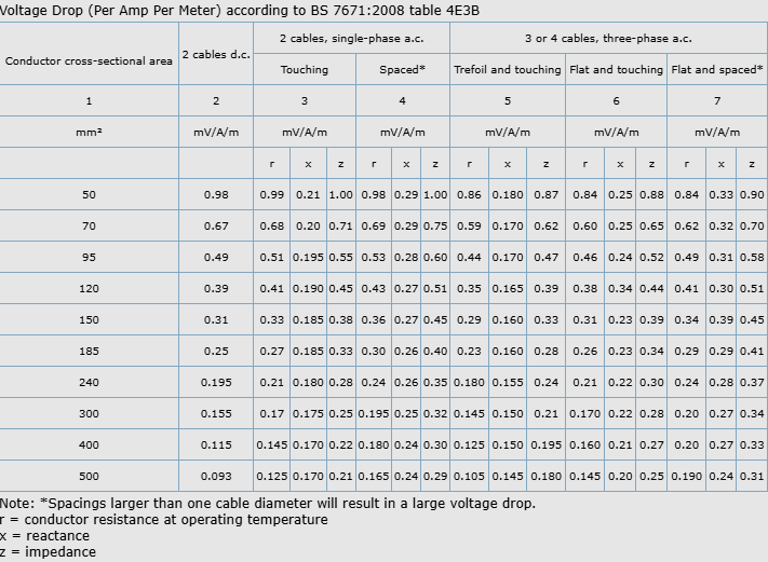

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E3A

Conductor cross- sectional area | Ref. Method c (clipped direct) | Ref. Method f (in free air or on a perforated cable tray, horizontal or vertical) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Touching | Touching | Spaced by on cable diameter | |||||||||

2 cables, single-phase a.c. or d.c. flat | 3 or 4 cables, three-phase a.c. flat | 2 cables, single- phase a.c. or d.c. flat | 3 or 4 cables, three-phase a.c. flat | 3 cables three-phase a.c. trefoil | 2 cables, d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | ||||

Horizontal | Vertical | Horizontal | Vertical | Horizontal | Vertical | ||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

mm² | A | A | A | A | A | A | A | A | A | A | A |

50 | 237 | 220 | 253 | 232 | 222 | 284 | 270 | 282 | 266 | 288 | 266 |

70 | 303 | 277 | 322 | 293 | 285 | 356 | 349 | 357 | 337 | 358 | 331 |

95 | 367 | 333 | 389 | 352 | 346 | 446 | 426 | 436 | 412 | 425 | 393 |

120 | 425 | 383 | 449 | 405 | 402 | 519 | 497 | 504 | 477 | 485 | 449 |

150 | 488 | 437 | 516 | 462 | 463 | 600 | 575 | 566 | 539 | 549 | 510 |

185 | 557 | 496 | 587 | 524 | 529 | 688 | 660 | 643 | 614 | 618 | 574 |

240 | 656 | 579 | 689 | 612 | 625 | 815 | 782 | 749 | 714 | 715 | 666 |

300 | 755 | 662 | 792 | 700 | 720 | 943 | 906 | 842 | 805 | 810 | 755 |

400 | 853 | 717 | 899 | 767 | 815 | 1137 | 1094 | 929 | 889 | 848 | 797 |

500 | 962 | 791 | 1016 | 851 | 918 | 1314 | 1266 | 1032 | 989 | 923 | 871 |

Introduction

In an era where urbanisation and industrial growth demand robust electrical infrastructure, the role of specialised power cables cannot be overstated. South Africa, with its expanding cities, critical power stations, and high-risk facilities, faces unique challenges in ensuring electrical safety amid fire hazards. The 600/1000V Mica+XLPE insulated, LSZH sheathed, armoured power cables, adapted from the IEC 60502-1 standard, represent a pinnacle of engineering designed for such environments. These single-core cables, often denoted as FFX300 1mRZ1MAZ1-R, integrate mica glass tape for fire barriers, cross-linked polyethylene (XLPE) insulation, low smoke zero halogen (LSZH) sheathing, and aluminium wire armouring to provide circuit integrity during fires while minimising toxic emissions.

Fire Performance and Compliance with Standards

Fire performance is the hallmark of these cables, addressing the devastating potential of fires in densely populated or critical facilities. Adapted from IEC 60502-1, they meet rigorous standards for circuit integrity (IEC 60331-21, EN 6387, BS 8491), ensuring functionality for at least 120 minutes under flame exposure at 750°C-830°C. This is achieved through the mica barrier, which forms a ceramic-like shield, preventing short circuits.

Flame retardance is tested via single vertical wire tests (IEC 60332-1-2, EN 60332-1-2), where the cable self-extinguishes without propagating fire. For bundled applications, reduced propagation is verified under IEC 60332-3-24 and EN 60332-3-24, simulating real-world installations in cable trays.

Halogen-free properties (IEC 60754-1, EN 50267-2-1) ensure no chlorine or bromine release, avoiding acid gas formation that could corrode equipment or harm humans. Low corrosive gas emission (IEC 60754-2, EN 50267-2-2) maintains pH levels above 4.3 and conductivity below 10 µS/mm. Minimum smoke emission (IEC 61034-2, EN 61034-2) limits density to below 60%, enhancing evacuation safety.

In scientific terms, LSZH materials decompose into non-toxic byproducts, reducing optical density and toxicity index. Comparative studies show LSZH cables emit 80% less smoke than PVC equivalents, a factor that has saved lives in fire scenarios. In South Africa, where building codes like SANS 10400-T mandate fire-resistant wiring in public buildings, these cables exceed requirements, promoting compliance and risk reduction.

Usage Scenarios: From Theory to Practice

These cables excel in high-risk applications: power stations for stable distribution, mass transit for emergency lighting, airports for control systems, petrochemical plants for explosion-prone areas, and hospitals/hotels/high-rises for life-safety circuits.

In power stations, armouring resists vibrations; in petrochemicals, hydrocarbon resistance prevents sheath breakdown. LSZH ensures safe evacuation in confined spaces.

The 600/1000V Mica+XLPE insulated, LSZH sheathed, armoured power cables to IEC 60502-1 embody advanced materials science and engineering, offering unparalleled fire resistance and electrical reliability. In South Africa, their adoption in case studies like CHBAH, ACSA, and Medupi illustrates tangible benefits in saving lives and assets. As infrastructure evolves, these cables will remain essential, driving safer, sustainable development.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430