Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V Mica+XLPE Insulated, LSZH Sheathed Power Cables to IEC 60502-1 (2-5 Cores & Multicore)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is CEand TUV approved.

STANDARDS

Basic design adapted from IEC 60502-1

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; EN 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas emission | IEC 60754-2; EN 50267-2-2 |

Minimum smoke emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

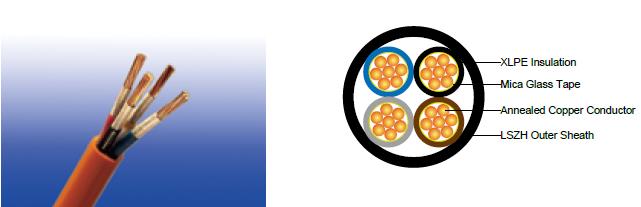

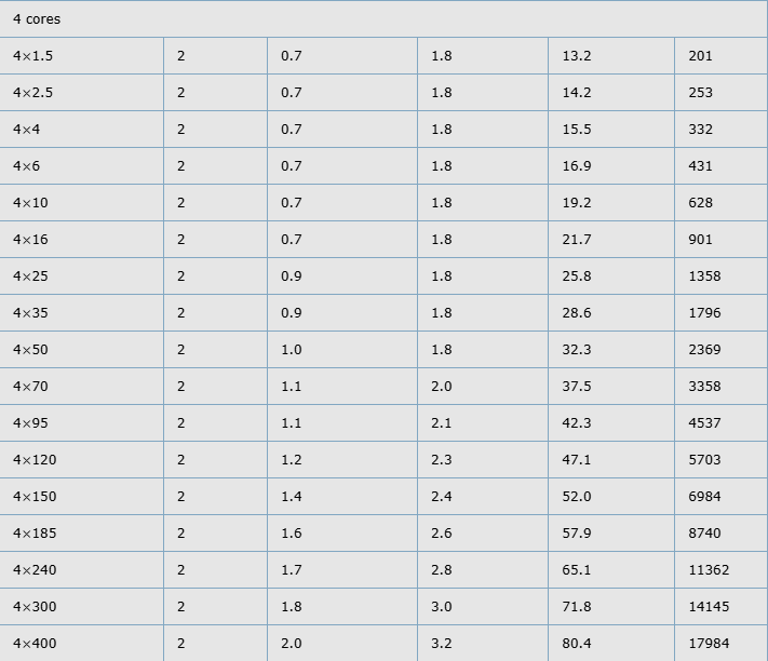

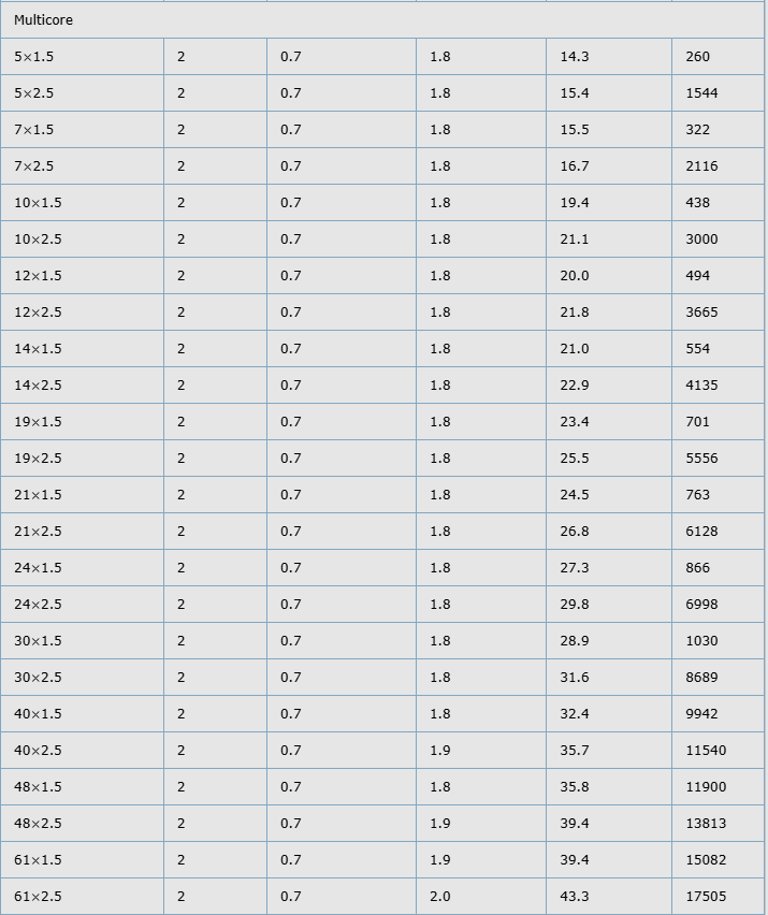

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Fire Barrier : Mica glass tape.

Insulation : Thermosetting XLPE material and thickness shall be as per IEC 60502-1.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour

2-core : Brown and blue.

3-core : Brown, black and grey.

4-core : Blue, brown, black and grey.

5-core : Green-and-yellow, blue, brown, black, grey.

Other colours can be offered upon request.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius

circular copper conductors OD≤25mm : 4 × Overall Diameter

circular copper conductors OD﹥25mm : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

Conductor cross-sectional area | Ref. Method A (enclosed in conduit in thermally insulating wall etc.) | Ref. Method B (enclosed in conduit on a wall or in trunking etc.) | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | 1 two-core cable*, single-phase a.c. or d.c. | 1 three- or four-core cable*, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm² | A | A | A | A | A | A | A | A |

1.5 | 18.5 | 16.5 | 22 | 19.5 | 24 | 22 | 26 | 23 |

2.5 | 25 | 22 | 30 | 26 | 33 | 30 | 36 | 32 |

4 | 33 | 30 | 40 | 35 | 45 | 40 | 49 | 42 |

6 | 42 | 38 | 51 | 44 | 58 | 52 | 63 | 54 |

10 | 57 | 51 | 69 | 60 | 80 | 71 | 86 | 75 |

16 | 76 | 68 | 91 | 80 | 107 | 96 | 115 | 100 |

25 | 99 | 89 | 119 | 105 | 138 | 119 | 149 | 127 |

35 | 121 | 109 | 146 | 128 | 171 | 147 | 185 | 158 |

50 | 145 | 130 | 175 | 154 | 209 | 179 | 225 | 192 |

70 | 183 | 164 | 221 | 194 | 269 | 229 | 289 | 246 |

95 | 220 | 197 | 265 | 233 | 328 | 278 | 352 | 298 |

120 | 253 | 227 | 305 | 268 | 382 | 322 | 410 | 346 |

150 | 290 | 259 | 334 | 300 | 441 | 371 | 473 | 399 |

185 | 329 | 295 | 384 | 340 | 506 | 424 | 542 | 456 |

240 | 386 | 346 | 459 | 398 | 599 | 500 | 641 | 538 |

300 | 442 | 396 | 532 | 455 | 693 | 576 | 741 | 621 |

400 | - | - | 625 | 536 | 803 | 667 | 865 | 741 |

Note: *With or without a protective conductor.

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

Conductor cross-sectional area | Two-core cables, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm² | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4 | 12 | 12 | 10 | ||||

6 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.38 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In South Africa, where rapid urbanisation and industrial growth collide with the ever-present risks of fire in densely populated environments, the demand for reliable electrical infrastructure has never been more pressing. Imagine a bustling Johannesburg hospital during a midnight emergency, or the humming corridors of Cape Town International Airport teeming with travellers—places where a single electrical fault could cascade into catastrophe. Enter the 600/1000V Mica+XLPE insulated, LSZH sheathed power cables to IEC 60502-1 (2-5 cores and multicore): engineering marvels designed not just to transmit power, but to preserve life and property when flames threaten.

These cables, often simply called Mica+XLPE fire-resistant power cables, represent a pinnacle of modern cable technology. Adapted from the International Electrotechnical Commission (IEC) 60502-1 standard, they integrate a mica glass tape fire barrier with cross-linked polyethylene (XLPE) insulation and a low smoke zero halogen (LSZH) outer sheath. Certified under CE and TUV approvals, they are tailored for high-stakes applications in power stations, mass transit systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. In a country like South Africa, where fire incidents in commercial buildings cost millions of rands annually—estimated at over R1 billion in insured losses in 2024 alone—these cables are more than wiring; they are silent guardians.

Fire Performance: Defying Flames in Critical Moments

Fire doesn't announce itself; it erupts, demanding cables that endure. These Mica+XLPE cables excel across a spectrum of fire tests, earning classifications like CWZ under BS 6387—resisting fire with water spray and mechanical shock. Circuit integrity under IEC 60331-21 and EN 6387 ensures power flows for 90 minutes at 750°C to 1,000°C, vital for fire pumps or emergency lifts in high-rises.

Flame retardance shines in single-cable vertical burns (IEC 60332-1-2), where the cable self-extinguishes without dripping ignited material. For bundled scenarios—think cable trays in petrochemical plants—IEC 60332-3-24 limits propagation to 2.5m, capping fire spread in enclosed spaces. Reduced smoke emission (IEC 61034-2) keeps visibility high for evacuations, while zero corrosive gases (IEC 60754-2) prevent equipment damage from acid mists.

Logically, this performance stems from material synergy: mica's incombustibility, XLPE's charring, and LSZH's clean burn. In South Africa, where urban fires rose 15% in 2024 per the Department of Human Settlements, these attributes comply with SANS 10400-T, mandating non-propagating materials in public assemblies. For instance, in hotels like those in Cape Town's V&A Waterfront, these cables wire smoke control systems, ensuring fans operate amid infernos.

Yet, fire performance isn't isolated; it intersects with installation. Clipped direct (Reference Method C) maximises heat dissipation, enhancing longevity in open-air airport runs. This rigorous testing—validated by TUV—positions these cables as a proactive shield, turning potential blackouts into sustained lifelines.

Usage Scenarios: From Power Grids to Urban Lifelines

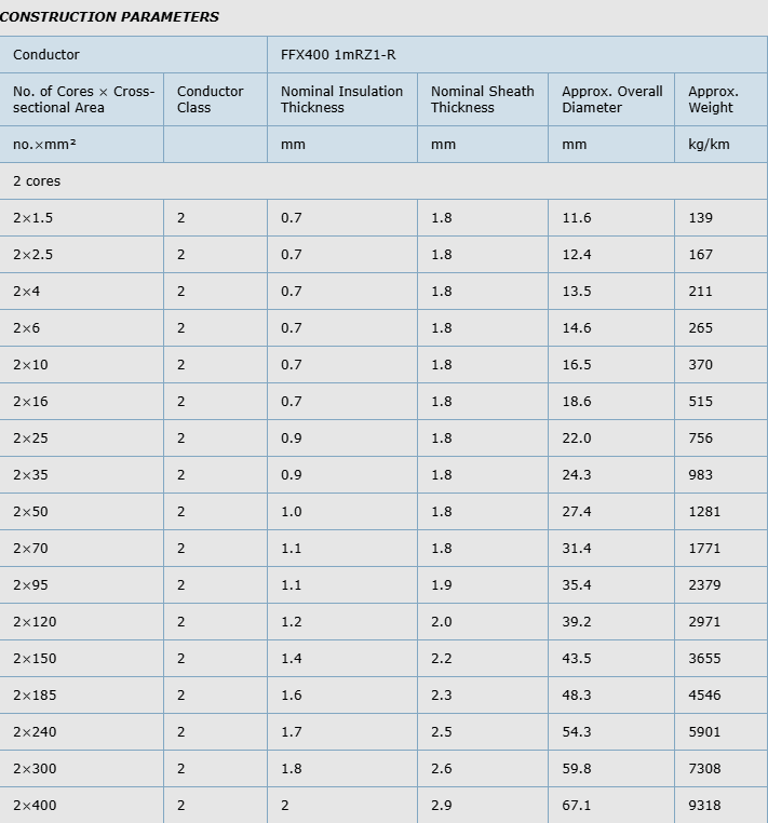

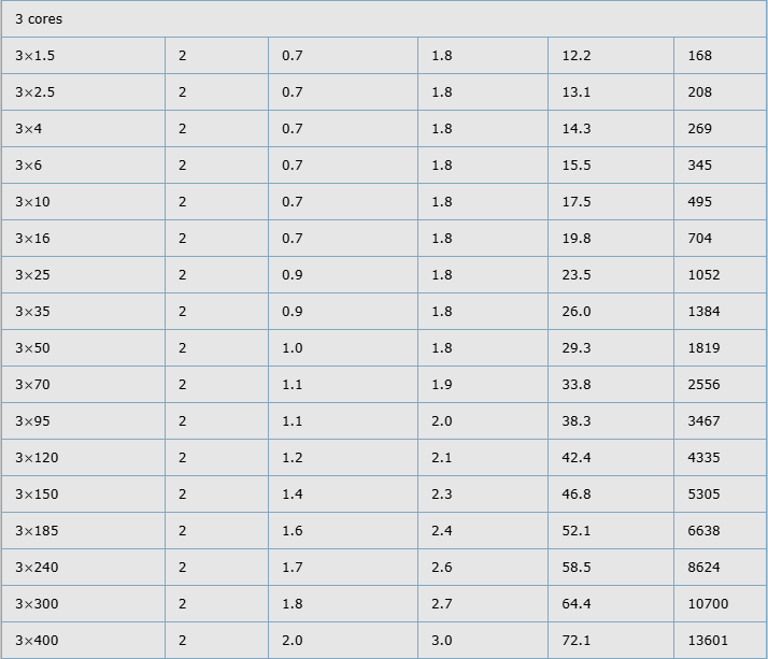

These cables thrive where failure isn't an option. In power stations like Kusile in Mpumalanga, 3x400mm² variants (72.1mm OD, 13,601kg/km) feed control circuits, their mica barrier ensuring shutdown sequences during faults. Mass transit, such as Gautrain tunnels, deploys 4x25mm² for signalling—flame-retardant bundles resisting propagation in confined spaces.

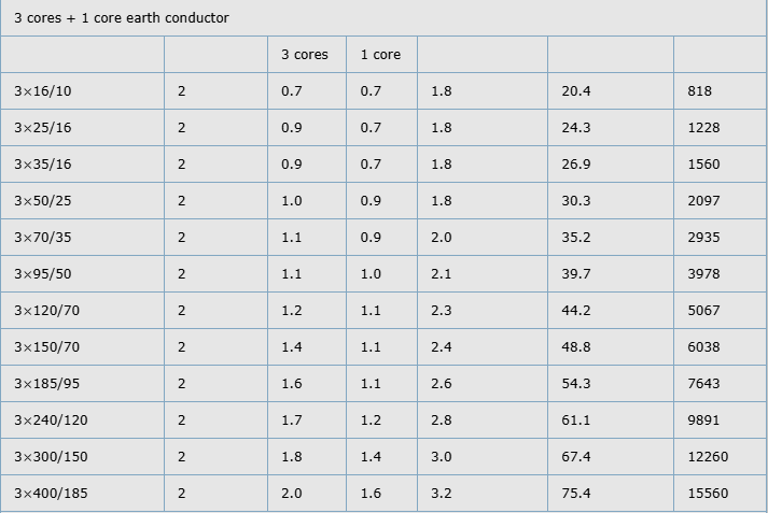

Airports like OR Tambo use multicore 19x2.5mm² (25.5mm OD) for baggage conveyors, LSZH minimising smoke in terminals. Petrochemical plants in Secunda opt for hydrocarbon-resistant sheaths on 2x185mm², enduring chemical spills. Hotels in Sun City wire emergency exits with 5x4mm², colour-coded for quick fault tracing. Hospitals demand circuit integrity for life-support; high-rises like Ponte Tower in Johannesburg route 3x150/70mm² (earth) up risers, bending at 6x OD.

Multicore shines in data centres or sewage plants, consolidating signals. Options like anti-termite for rural installs address South Africa's biodiversity threats. Overall, installation per SANS 10142-1—trayed or ducted—maximises ratings, with UV options for solar farms.

The 600/1000V Mica+XLPE insulated, LSZH sheathed power cables to IEC 60502-1 stand as a testament to innovation meeting necessity. From their robust construction and stellar fire performance to precise electrical specs and proven scenarios, they deliver logical, life-saving reliability. In South Africa, where 2025's Fire Safety Compliance Guide mandates such advancements, recent case studies at airports, hospitals, and metros affirm their impact—slashing risks and costs in an era of escalating urban fires.

As we push towards net-zero buildings and resilient grids, specifying these cables isn't optional; it's imperative. Consult SANS-compliant suppliers like Versalec for tailored integrations, ensuring your projects illuminate safely. In the words of a CHBAH engineer: "These cables don't just carry current; they carry hope." Let's wire South Africa for a fire-proof future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430