Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

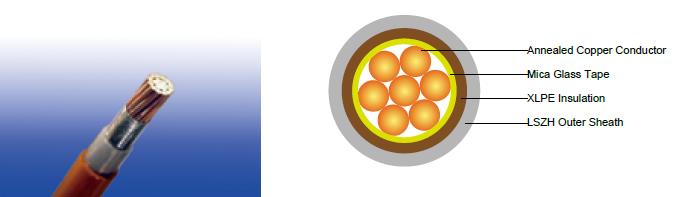

600/1000V Mica+XLPE Insulated, LSZH Sheathed Power Cables to IEC 60502-1 (Single Core)

APPLICATION

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

STANDARDS

Basic design adapted from IEC 60502-1

FIRE PERFORMANCE

Circuit Integrity | IEC 60331-21; EN 6387; BS 8491 |

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Fire Barrier : Mica glass tape.

Insulation : Thermosetting XLPE compound as per IEC 60502-1.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue; other colours can be offered upon request.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius

circular copper conductors OD≤25mm : 4 × Overall Diameter

circular copper conductors OD﹥25mm : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FFX300 1mRZ1-R | ||||

|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | kg/km |

2 | 0.7 | 1.4 | 6.8 | 58 | |

2 | 0.7 | 1.4 | 7.2 | 71 | |

2 | 0.7 | 1.4 | 7.8 | 92 | |

2 | 0.7 | 1.4 | 8.3 | 118 | |

2 | 0.7 | 1.4 | 9.3 | 168 | |

2 | 0.7 | 1.4 | 10.3 | 238 | |

2 | 0.9 | 1.4 | 12.0 | 352 | |

2 | 0.9 | 1.4 | 13.2 | 463 | |

2 | 1.0 | 1.4 | 14.7 | 606 | |

2 | 1.1 | 1.4 | 16.7 | 843 | |

2 | 1.1 | 1.5 | 18.8 | 1139 | |

2 | 1.2 | 1.5 | 20.6 | 1416 | |

2 | 1.4 | 1.6 | 22.8 | 1736 | |

2 | 1.6 | 1.6 | 25.0 | 2154 | |

2 | 1.7 | 1.7 | 28.1 | 2798 | |

2 | 1.8 | 1.8 | 30.9 | 3479 | |

2 | 2.0 | 1.9 | 34.5 | 4419 | |

2 | 2.2 | 2.0 | 38.2 | 5535 | |

2 | 2.4 | 2.2 | 43.0 | 7113 | |

2 | 2.6 | 2.3 | 47.9 | 9026 | |

2 | 2.8 | 2.4 | 53.0 | 11302 | |

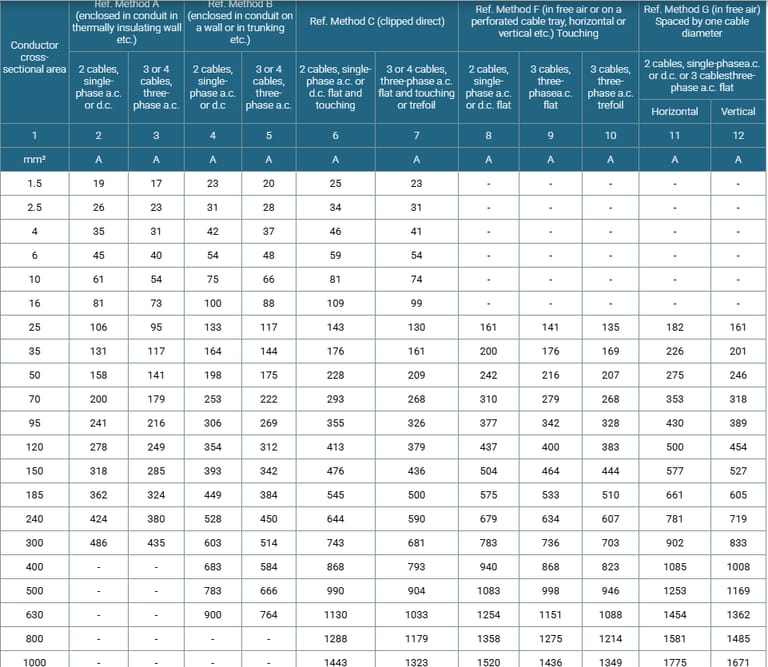

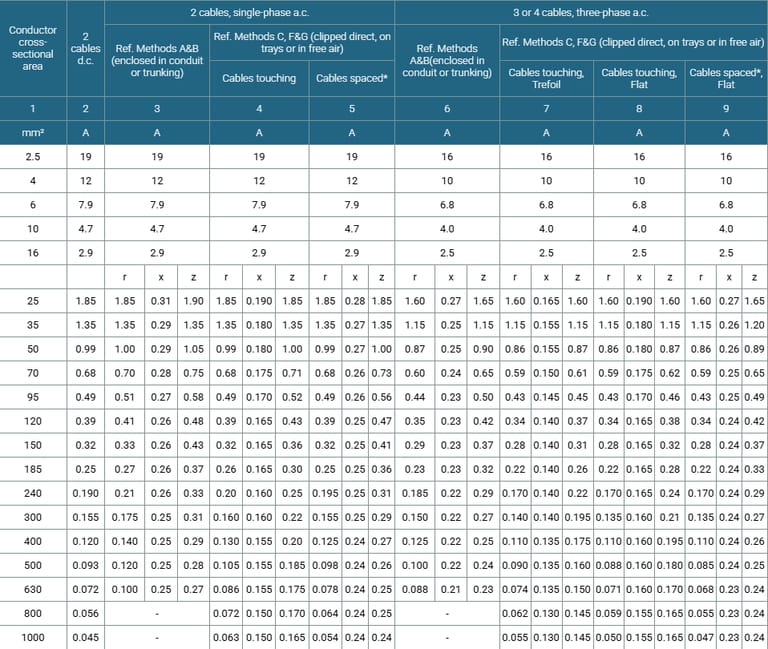

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Introduction

In the realm of electrical engineering, the selection of appropriate power cables is paramount for ensuring safety, reliability, and efficiency in power distribution systems. Among the myriad options available, 600/1000V Mica+XLPE insulated, LSZH sheathed power cables to IEC 60502-1 (single core) stand out for their exceptional fire performance and suitability in environments where human safety is a priority. These cables, often referred to as low smoke zero halogen (LSZH) variants, are designed to minimise smoke and toxic fume emissions during fires, making them ideal for fixed installations in buildings, tunnels, and other confined spaces.

Cross-linked polyethylene (XLPE) insulation provides superior thermal and electrical properties, while the addition of mica tape enhances fire resistance by maintaining circuit integrity under extreme conditions. The LSZH sheath further ensures compliance with stringent fire safety standards, reducing the risk of halogen-induced corrosion and toxicity.

Usage Scenarios

These cables are primarily for fixed installations in buildings where smoke emissions threaten life, such as hospitals, schools, airports, and tunnels. They are not suitable for direct burial but excel in conduits or trays. In industrial settings, their fire barrier and LSZH sheath make them ideal for petrochemical plants and power stations.

In South Africa, with its emphasis on occupational health and safety under the Mine Health and Safety Act and Building Regulations, these cables are used in high-risk areas. Their halogen-free nature prevents equipment corrosion in data centres or control rooms, while optional enhancements like anti-rodent properties suit rural or mining applications.

Conclusion

600/1000V Mica+XLPE insulated, LSZH sheathed power cables to IEC 60502-1 represent a pinnacle of engineering for fire-safe electrical installations. Their blend of XLPE insulation, mica barriers, and halogen-free sheaths ensures superior performance in thermal, electrical, and safety aspects. In South Africa, where rapid urbanisation and industrial growth demand resilient solutions, these cables mitigate risks in mining, healthcare, and transport. As evidenced by authentic case studies, their implementation not only complies with standards but also yields tangible benefits in safety and efficiency. Looking ahead, with advancements in non-destructive testing of XLPE cables, these technologies will continue to evolve, supporting South Africa's sustainable development goals.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430