Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V, PVC Insulated and Lead Sheathed Cables according to IEC 60502-1

Application

These cables are used for electricity supply in low voltage installation system, They are suitable for installation in indoors and outdoors, in cable ducts, under ground, in power and switching stations, local energy distributions, industrial plants, where there is no risk of mechanical damage. The lead sheath brings an enhanced resistance to aromatic hydrocarbons.

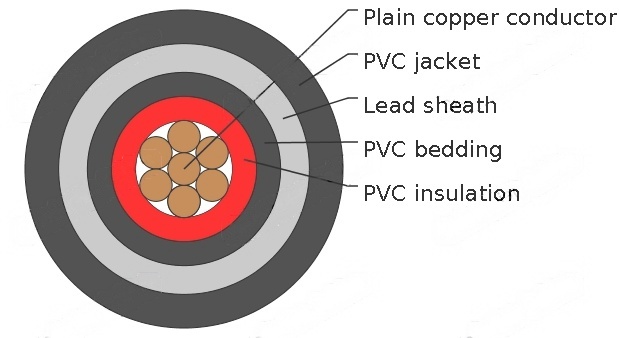

Construction

Conductors

The conductors shall be either of Class 1 or Class 2 of plain or metal-coated annealed copper or of plain aluminium or aluminium alloy, or of Class 5 of plain or metal-coated copper in accordance with IEC 60228.

Insulation

PVC Insulation material and thickness shall be as per IEC 60502-1, PVC material shall be Type A as per IEC 60502-1.

Colour Code

Colour Code (1)

1 Core | Red or Black |

2 Cores | Red, Black |

3 Cores | Red, Yellow, Blue |

4 Cores | Red, Yellow, Blue, Black |

5 Cores | Red, Yellow, Blue, Black, Green |

Above 5 Cores | Black Cores with White numerals |

Colour Code (2)

1 Core | Brown or Blue |

2 Cores | Brown, Blue |

3 Cores | Brown, Black, Grey |

4 Cores | Blue, Brown, Black, Grey |

5 Cores | Green/Yellow, Blue, Brown, Black, Grey |

Above 5 Cores | Black Cores with White numerals |

Other colours can be manufactured upon request.

Assembly / Inner Covering

The inner coverings may be extruded or lapped. For cables with circular cores, except cables with more than five cores, a lapped inner covering shall be permitted only if the interstices between the cores are substantially filled. A suitable binder is permitted before application of an extruded inner covering. The materials used for inner coverings and fillers shall be suitable for the operating temperature of the cable and compatible with the insulating material.For halogen free cables, the inner covering and fillers shall also be halogen free compound.

Lead Sheath

lead or lead alloy and shall be applied as a reasonably tight-fitting seamless tube.

Seperation Sheath

The seperation sheath shall be of extruded PVC Type ST2 as per IEC 60502-1, or other material refer to outer sheath material.

Armour

Aluminum/galvanized steel/steel wires applied helically over the Inner Covering as per IEC 60502-1, or double aluminum/steel tapes and copper/tinned copper wire can also be manufactured upon request.

Outer Sheath

Outer sheath shall be of extruded PVC Type ST1/ST2 as per IEC 60502-1, Polyethylene type ST3/ST7, Halogen free compound ST8, Polychloroprene, chlorosulfonated polyethylene or similar polymers, type SE1 are also available on request.

Applications in Low Voltage Systems

These cables are engineered for electricity supply in low voltage installation systems, typically rated at 600/1000V, where reliability under varied conditions is paramount. They are versatile, suitable for indoor and outdoor use, including cable ducts, underground burial, power stations, switching stations, local energy distributions, and industrial plants. A key limitation is that they should not be installed where there is a risk of mechanical damage, unless armoured variants are employed.

One of the standout features is the lead sheath, which provides enhanced resistance to aromatic hydrocarbons—chemicals commonly found in petroleum-based environments or industrial solvents. This makes the cables ideal for petrochemical plants, refineries, or areas with potential exposure to such substances, preventing degradation that could compromise insulation integrity. In South African contexts, where mining and heavy industry dominate, these cables support critical infrastructure without succumbing to corrosive elements.

Beyond basic power supply, their design caters to scenarios requiring chemical resilience. For instance, in underground installations, the lead sheath acts as a barrier against soil contaminants, ensuring long-term performance. This aligns with IEC 60502-1's emphasis on environmental compatibility, reducing the need for frequent replacements and minimising downtime in energy-intensive operations.

Advantages and Compliance Considerations

The integration of PVC insulation with lead sheathing offers superior chemical resistance, making these cables preferable over standard PVC types in contaminated environments. Armour variants add mechanical fortitude, crucial in South Africa's mining sector where cables face abrasion.

Compliance with IEC 60502-1 guarantees testing for partial discharge, ageing, and impact resistance. Halogen-free options address environmental concerns, reducing acid gas emissions.

In comparison to non-lead sheathed cables, these provide better longevity in hydrocarbon-rich areas, though lead's environmental impact necessitates careful disposal per regulations.

The 600/1000V PVC insulated lead sheathed cables exemplify engineering excellence under IEC 60502-1, balancing conductivity, protection, and versatility. From conductors to outer sheaths, each element is optimised for low voltage applications, ensuring safety and efficiency. As industries evolve, these cables remain indispensable, supporting sustainable power infrastructure.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430