Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V PVC Insulated, PVC Sheathed, Armoured Power Cables to BS 6346 (2-5 Cores)

Application

The cables are intended for use in fixed installations in industrial areas, buildings and similar applications.

Standards

Basic design to BS 6346

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 50265-2-1 |

Voltage Rating

600/1000V

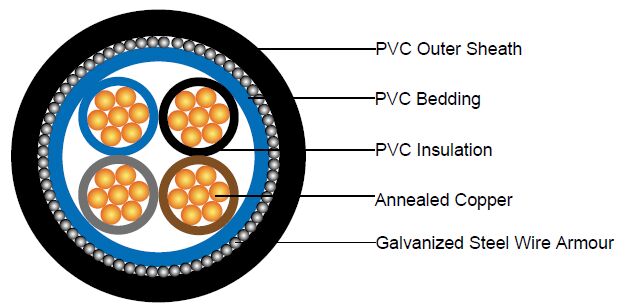

Cable Construction

Conductor | Annealed copper wire, stranded according to BS 6360 class 2. |

Insulation | PVC TI 1 according to BS 7655-3.1. |

Bedding | Extruded PVC or taped bedding comprising two or more layers of PVC tape or other synthetic tape (for cables having a nominal conductor area of 16mm² and above). |

Armouring | Galvanized steel wire |

Outer Sheath | PVC TM 1 according to BS 7655-4.1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Two-core: Brown, blue |

Sheath Colour | Black (other colours upon request) |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C |

Maximum short circuit temperature (5 Seconds) | 160°C |

Minimum bending radius | |

Circular copper conductors | 6 x Overall Diameter |

Shaped copper conductors | 8 x Overall Diameter |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 70°C |

Ambient Temperature | 30°C |

Current-Carrying Capacities (Amp) according to BS 7671: 2008 table 4D4A

Conductor crosssectional | Reference Method C (clipped direct) | Reference Method E (in free air | Reference Method D (direct in in | |||

|---|---|---|---|---|---|---|

1 two-core cable*, | 1 three-or four | 1 two-core | 1 three-or four | 1 two-core cable*, | 1 three-or four | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm2 | A | A | A | A | A | A |

1.5 | 21 | 18 | 22 | 19 | 22 | 18 |

2.5 | 28 | 25 | 31 | 26 | 29 | 24 |

4.0 | 38 | 33 | 41 | 35 | 37 | 30 |

6.0 | 49 | 42 | 53 | 45 | 46 | 38 |

10 | 67 | 58 | 72 | 62 | 60 | 50 |

16 | 89 | 77 | 97 | 83 | 78 | 64 |

25 | 118 | 102 | 128 | 110 | 99 | 82 |

35 | 145 | 125 | 157 | 135 | 119 | 98 |

50 | 175 | 151 | 190 | 163 | 140 | 116 |

70 | 222 | 192 | 241 | 207 | 173 | 143 |

95 | 269 | 231 | 291 | 251 | 204 | 169 |

120 | 310 | 267 | 336 | 290 | 231 | 192 |

150 | 356 | 306 | 386 | 332 | 261 | 217 |

185 | 405 | 348 | 439 | 378 | 292 | 243 |

240 | 476 | 409 | 516 | 445 | 336 | 280 |

300 | 547 | 469 | 592 | 510 | 379 | 316 |

400 | 621 | 540 | 683 | 590 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS 7671: 2008 table 4D4B

Nominal Cross Section Area | Two-core cables d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm2 | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 29 | 29 | 25 | ||||

2.5 | 18 | 18 | 15 | ||||

4.0 | 11 | 11 | 9.5 | ||||

6.0 | 7.3 | 7.3 | 6.4 | ||||

10 | 4.4 | 4.4 | 3.8 | ||||

16 | 2.8 | 2.8 | 2.4 | ||||

|

| r | x | z | r | x | z |

25 | 1.75 | 1.75 | 0.170 | 1.75 | 1.50 | 0.145 | 1.50 |

35 | 1.25 | 1.25 | 0.165 | 1.25 | 1.10 | 0.145 | 1.10 |

50 | 0.93 | 0.93 | 0.165 | 0.94 | 0.80 | 0.140 | 0.81 |

70 | 0.63 | 0.63 | 0.160 | 0.65 | 0.55 | 0.140 | 0.57 |

95 | 0.46 | 0.47 | 0.155 | 0.50 | 0.41 | 0.135 | 0.43 |

120 | 0.36 | 0.38 | 0.155 | 0.41 | 0.33 | 0.135 | 0.35 |

150 | 0.29 | 0.30 | 0.155 | 0.34 | 0.26 | 0.130 | 0.29 |

185 | 0.23 | 0.25 | 0.150 | 0.29 | 0.21 | 0.130 | 0.25 |

240 | 0.180 | 0.190 | 0.150 | 0.24 | 0.165 | 0.130 | 0.21 |

300 | 0.145 | 0.155 | 0.145 | 0.21 | 0.135 | 0.130 | 0.185 |

400 | 0.105 | 0.115 | 0.145 | 0.185 | 0.100 | 0.125 | 0.160 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In the heart of South Africa's bustling industrial landscape, where reliability and safety are paramount, power cables form the unseen backbone of electricity distribution. Among these, the 600/1000V PVC insulated, PVC sheathed, armoured power cables to BS 6346 (covering 2 to 5 cores) stand out as robust solutions designed for demanding environments. These cables, often referred to simply as PVC armoured cables, are engineered to deliver power efficiently while withstanding mechanical stress, environmental hazards, and fire risks.

Compliant with the British Standard BS 6346, these cables are ideal for fixed installations in industrial areas, buildings, and similar applications. In South Africa, where mining, manufacturing, and urban development drive the economy, such cables ensure uninterrupted power supply in challenging conditions like underground mines or high-traffic construction sites.

Application Scenarios

Armoured power cables in action, suitable for South African industrial and mining environments.

These cables are tailored for fixed installations where durability is key. In industrial areas, they power machinery in refineries, chemical plants, and manufacturing facilities, protected by their armour against impacts and rodents. In buildings, they support electrical systems in commercial and residential structures, ensuring safe power distribution.

In South Africa, armoured cables like these are vital for infrastructure projects, including urban power grids in cities like Johannesburg and rural electrification initiatives. The mining sector, a cornerstone of the economy, relies on them for underground operations where mechanical stress and environmental hazards are common. They are also used in transportation hubs and power distribution networks managed by entities like Eskom, adapting to the country's diverse climates from coastal humidity to inland dryness.

Advantages

The armoured design provides superior mechanical protection compared to unarmoured alternatives, reducing downtime and maintenance costs. Their flame-retardant properties enhance safety in fire-prone areas, while optional features like oil and UV resistance make them versatile for harsh South African conditions. Cost-effective over time, they offer reliable performance with low voltage drops, ensuring efficient energy transmission. In comparison to other cables, their compliance with BS 6346 guarantees quality, making them a preferred choice for long-term installations.

FAQs

What is the voltage rating of these cables?

They are rated at 600/1000V, suitable for low-voltage power distribution.

Can they be used outdoors?

Yes, with optional UV and weather-resistant sheaths, they are ideal for outdoor fixed installations.

What is the maximum operating temperature?

70°C continuously, with short-circuit tolerance up to 160°C for 5 seconds.

Are they fire-resistant?

They meet flame retardance standards like BS EN 50265-2-1, with options for enhanced fire performance.

How do I choose the right core count?

It depends on the application: 2 cores for single-phase, 3-5 cores for three-phase or control systems.

What bending radius should I follow?

6x overall diameter for circular conductors, 8x for shaped, to avoid damage during installation.

In conclusion, these 600/1000V PVC armoured power cables are a testament to engineering ingenuity, powering South Africa's progress with reliability and safety at their core. Whether in mines or modern buildings, they ensure the lights stay on.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430