Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V PVC Insulated, PVC Sheathed, Armoured Power Cables to IEC 60502 (2-4 Cores)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

Standards

Basic design adapted to IEC 60502-1

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1-2 |

Voltage Rating

600/1000V

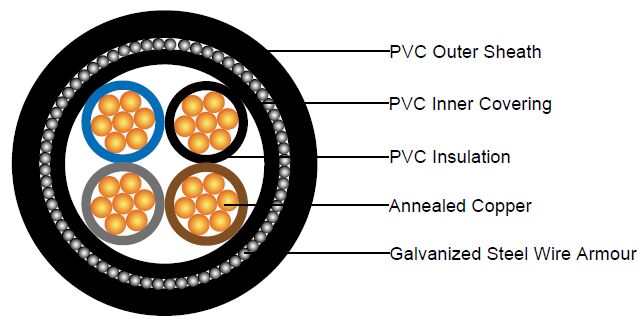

Cable Construction

Conductor | Annealed copper wire, stranded according to IEC 60228 class 2. |

Insulation | PVC/A according to IEC 60502-1. |

Inner Covering | Extruded PVC or polymeric compound. |

Armouring | Galvanized steel wire |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Two-core: Brown, blue |

Sheath Colour | Black, other colours can be offered upon request. |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C |

Maximum short circuit temperature (5 Seconds) | 160°C(≤300 mm²); 140°C(>300 mm²) |

Minimum bending radius | |

Circular copper conductors | 6 x Overall Diameter |

Shaped copper conductors | 8 x Overall Diameter |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 70°C |

Ambient Temperature | 30°C |

Current-Carrying Capacities (Amp) according to BS 7671: 2008 table 4D4A

Conductor crosssectional | Reference Method C (clipped direct) | Reference Method E (in free air or | Reference Method D (direct in in | |||

|---|---|---|---|---|---|---|

1 two-core cable, | 1 three-or four | 1 two-core | 1 three-or four | 1 two-core cable, | 1 three-or four | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm2 | A | A | A | A | A | A |

1.5 | 21 | 18 | 22 | 19 | 22 | 18 |

2.5 | 28 | 25 | 31 | 26 | 29 | 24 |

4.0 | 38 | 33 | 41 | 35 | 37 | 30 |

6.0 | 49 | 42 | 53 | 45 | 46 | 38 |

10 | 67 | 58 | 72 | 62 | 60 | 50 |

16 | 89 | 77 | 97 | 83 | 78 | 64 |

25 | 118 | 102 | 128 | 110 | 99 | 82 |

35 | 145 | 125 | 157 | 135 | 119 | 98 |

50 | 175 | 151 | 190 | 163 | 140 | 116 |

70 | 222 | 192 | 241 | 207 | 173 | 143 |

95 | 269 | 231 | 291 | 251 | 204 | 169 |

120 | 310 | 267 | 336 | 290 | 231 | 192 |

150 | 356 | 306 | 386 | 332 | 261 | 217 |

185 | 405 | 348 | 439 | 378 | 292 | 243 |

240 | 476 | 409 | 516 | 445 | 336 | 280 |

300 | 547 | 469 | 592 | 510 | 379 | 316 |

400 | 621 | 540 | 683 | 590 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS 7671: 2008 table 4D4B

Nominal Cross Section Area | Two-core cables d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm2 | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 29 | 29 | 25 | ||||

2.5 | 18 | 18 | 15 | ||||

4.0 | 11 | 11 | 9.5 | ||||

6.0 | 7.3 | 7.3 | 6.4 | ||||

10 | 4.4 | 4.4 | 3.8 | ||||

16 | 2.8 | 2.8 | 2.4 | ||||

|

| r | x | z | r | x | z |

25 | 1.75 | 1.75 | 0.170 | 1.75 | 1.50 | 0.145 | 1.50 |

35 | 1.25 | 1.25 | 0.165 | 1.25 | 1.10 | 0.145 | 1.10 |

50 | 0.93 | 0.93 | 0.165 | 0.94 | 0.80 | 0.140 | 0.81 |

70 | 0.63 | 0.63 | 0.160 | 0.65 | 0.55 | 0.140 | 0.57 |

95 | 0.46 | 0.47 | 0.155 | 0.50 | 0.41 | 0.135 | 0.43 |

120 | 0.36 | 0.38 | 0.155 | 0.41 | 0.33 | 0.135 | 0.35 |

150 | 0.29 | 0.30 | 0.155 | 0.34 | 0.26 | 0.130 | 0.29 |

185 | 0.23 | 0.25 | 0.150 | 0.29 | 0.21 | 0.130 | 0.25 |

240 | 0.180 | 0.190 | 0.150 | 0.24 | 0.165 | 0.130 | 0.21 |

300 | 0.145 | 0.155 | 0.145 | 0.21 | 0.135 | 0.130 | 0.185 |

400 | 0.105 | 0.115 | 0.145 | 0.185 | 0.100 | 0.125 | 0.160 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance

What Are 600/1000V PVC Insulated Armoured Power Cables?

Imagine a cable that's not just a wire but a fortified conduit for electricity. These cables are rated for voltages up to 600/1000V, meaning they're suited for low-voltage power distribution where safety and efficiency are paramount. The "PVC insulated" part refers to polyvinyl chloride, a tough plastic that wraps around the copper conductors to prevent electrical leaks and short circuits. The "PVC sheathed" outer layer adds another barrier against moisture and chemicals, while the "armoured" aspect involves galvanised steel wires that protect against physical damage—like being crushed or chewed by rodents.

Adapted to the international standard IEC 60502-1, these cables ensure consistent quality worldwide. They're flame retardant, tested to IEC 60332-1-2, so they won't easily spread fire in an emergency. Available in configurations from 2 cores (for simpler setups) to 4 cores (for more complex three-phase systems), they come with options like UV resistance or anti-termite properties, making them adaptable to harsh conditions.

Application Scenarios

These cables shine in environments where reliability is non-negotiable. Primarily, they're deployed in power stations for distributing electricity safely. In mass transit systems like underground passenger networks, their armour protects against vibrations and impacts. Airports rely on them for lighting and control systems, while petrochemical plants appreciate their hydrocarbon-resistant options.

In urban settings, they're ideal for hotels, hospitals, and high-rise buildings, where fire safety and minimal downtime are crucial. Buried underground or clipped to walls, they handle everything from single-phase AC to three-phase systems.

In South Africa, with its diverse landscapes and growing infrastructure, these cables fit perfectly. They're used in rural electrification projects to bring power to remote areas, enduring dust and wildlife. Urban grids in cities like Johannesburg benefit from their durability against theft and vandalism—common issues in some regions.

Advantages

Why choose these over cheaper alternatives? First, durability: The steel armour guards against mechanical abuse, extending lifespan and reducing maintenance costs. Second, safety: Flame retardance and low smoke options (LSPVC on request) make them suitable for public spaces, complying with standards like UL 1581.

Third, versatility: Custom options for UV, oil, or pest resistance tailor them to specific needs, like South Africa's sunny climates or termite-prone areas. Electrically efficient with low voltage drop, they save energy over time. Compared to unarmoured cables, they're pricier upfront but offer long-term savings through fewer failures.

In eco terms, PVC is recyclable, and their efficiency cuts carbon footprints in power distribution.

FAQs

Q: What does IEC 60502-1 mean for these cables?

A: It's an international standard ensuring the cables meet global benchmarks for construction, insulation, and performance, adapted for safe use in various countries, including South Africa.

Q: Are these cables suitable for outdoor use in South Africa?

A: Yes, with options for UV and anti-termite resistance, they're perfect for our varied weather—from Gauteng's thunderstorms to the Western Cape's winds.

Q: How do I choose between 2-core and 4-core?

A: 2-core suits single-phase setups like home lighting; 4-core handles three-phase for industrial motors. Consult an electrician based on load requirements.

Q: What's the lifespan of these cables?

A: Typically 25-30 years, depending on installation and environment, thanks to their robust design.

Q: Can they be used in fire-prone areas?

A: Absolutely—their flame retardance meets IEC 60332, making them ideal for hospitals and high-rises.

In summary, these 600/1000V PVC insulated armoured power cables are more than wires; they're the unsung guardians of our powered world, blending science, safety, and sustainability. For South Africans, they're key to building a resilient future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430